High-efficiency pumps

High efficiency pumps are special pumping devices designed to provide maximum performance and efficiency in pumping liquids or gases. They feature advanced design and innovative technologies that reduce energy consumption and increase pump efficiency. High efficiency pumps are widely used in a variety of industries, including water supply, heating, air conditioning, oil and gas, and chemicals. Their use reduces operating costs and increases the productivity of production processes, making them an important element in engineering systems and technological processes.

TOP-53 High-efficiency + other products

VKC Sealless Mag-Drive Vertical Pumps

The vertical centrifugal pump is designed to submerge the pump in the pumped liquid so that the electric motor remains above the liquid level. The semi-submersible chemical pump uses special construction materials and technical solutions that allow it to withstand chemical attack not only from the inside but also from the outside. We offer sealed semi-submersible vertical pumps with magnetic coupling and pumps with mechanical seal for pumping sodium hydroxide and hypochlorite, sulfuric, hydrochloric, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities, etc.

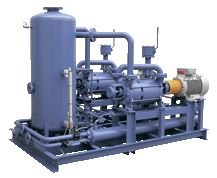

Single stage liquid ring vacuum pumps AVM & AVL

The AVM and AVL series consist of single-stage liquid ring vacuum pumps designed to achieve deep vacuum. Both series have the same hydraulics but different designs.

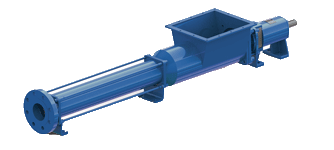

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Dry Screw Pumps AVVS series

AVVS series consists in dry screw vacuum pumps designed tooperate at very deep vacuum capable to achieve 0,05 mbar or deeper if combined with a booster pump. The new patented hybrid screw design ensures higher efficiency due to lower temperature and less power consumption. Different type of coatings protect the internals from corrosion caused by aggressive gas mixture and vapors typical of the process industry, chemical, pharmaceutical and petrochemical applications.

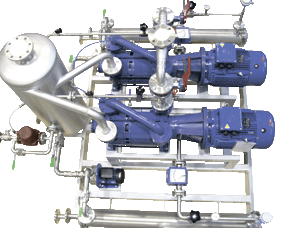

Liquid ring vacuum pump systems & centralized units

Liquid ring vacuum pump systems designed to meet most needs of vacuum of the industry. Developed with one or more pumps acting in parallel depending on the specific needs, the systems are equipped with dedicated equipment for service liquid cooling and recirculation including instrumentation and devices for control and full remote automatic operation including control panel with PLC and VFD. Units for hazardous area, on request.

Heavy duty & API 681 liquid ring vacuum pumps & systems

Liquid ring vacuum pumps and systems meeting API 681 standards for chemical and petrochemical applications. Suitable for heavy duties, are available in different exotic materials with single or double cartridge API 682 cartridge mechanical seals. Package design standards in line with most stringent project specifications and quality requirements.

Liquid ring pump condenser exhausters

Liquid ring vacuum pumps are used in centralised vacuum systems and in power generation. The vacuum systems consist of exhaust ventilation units for the main condenser and filling units for the water condenser. The systems are designed for both load and hold modes.

In many cases, the pump is assisted by a first stage gas or steam ejector to improve pump performance at different condenser loads. The ASCO VACUUM team has extensive experience in geothermal applications.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

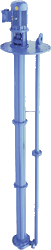

Vertical centrifugal pumps

You can buy centrifugal vertical single-stage pumps of the NCV series from ASCO PUMPS Ukraine. The maximum shaft length is 5 m. The standard design is designed for rotational speeds up to 2900 rpm. The radial bearings are lubricated by the pumped liquid, provided it does not contain any suspended abrasive particles. If the pumped fluid is slightly abrasive, the radial bearings are lubricated with an external special transparent grease.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

Motor speed gear pumps

Viking's motor-speed industrial pumps are designed for increased performance by using double ball bearings and a direct motor-pump arrangement. Reliable mechanical seals and gaskets eliminate leakage and extend pump life.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Two-stage liquid ring vacuum pumps of the AVD series

Two-stage vacuum pumps of the AVD-AVDL series are capable of creating a maximum residual pressure of up to 33 mbar. They are in demand in cases where it is necessary to pump out various moisture in the form of steam or liquids in sufficiently large quantities. The reliability of the products is beyond doubt, they are easy to maintain, and they can be used to pump out any gas or vapour. Materials used for manufacturing range from high-quality, particularly resistant cast iron to stainless steel of the highest grades, for example, AISI 316.

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Side Channel Blowers

Blowers are an excellent choice for many automated projects where the application requires large volumes of clean, dry air at low pressure and vacuum. We strive to provide a solution that allows for easy installation, yet provides low operating noise and energy savings in a small, lightweight design.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Semi-welded plate heat exchangers SIGMADUAL

SIGMADUAL heat exchangers are the latest and most efficient device for transferring heat energy from a source to a destination, which can also be used for cooling purposes. Both liquids (preferably non-freezing) and gaseous substances can move in the channels of the corrugated plates as a working medium.

Plate & shell heat exchangers SIGMASHELL

SIGMASHELL heat exchangers are a unique combination of the strength and high pressure capability of shell-and-tube heat exchangers with the compactness and high thermal efficiency of plate heat exchangers.

Gasketed plate heat exchangers SIGMA

SIGMA plate heat exchangers have excellent design characteristics that ensure their durability and reliability. Plate heat exchangers use corrugated plates that are placed between a fixed and movable pressure plate. Due to the fact that almost all of the material is used for heat transfer, plate heat exchangers have a large effective heat transfer area with a minimum of space. Often, a plate heat exchanger can deliver the same heat transfer capacity as a shell-and-tube heat exchanger that is five times larger in volume.

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

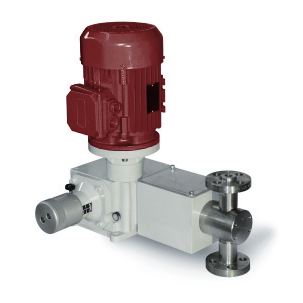

TITANO Series

The pumps of the TITANO series are designed and manufactured according to API 674 and ASME standards and cover the range of medium power up to 600 kW.

These pumps are studied to guarantee a highly reliable service and to minimize the maintenance operations and the operating costs.

The TITANO series consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex model are used.

PTO/PQO/PSO series

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

Simplex PD Plunger Pumps

The pumps in this series feature a mechanical plunger return stroke and have adjustable stroke settings from 0 to 100%, providing flexibility in operation and dosing accuracy of more than 1% over a performance range of 10 to 100%. These liquid dosing pumps maintain the required NPSH below 0.3 bar abs under standard conditions.

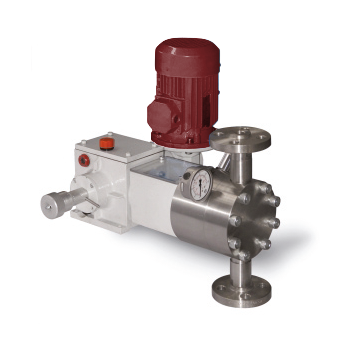

Simplex PD Diaphragm Pumps

The series is designed adopting hydraulically actuated double sandwich diaphragms with intermediate vacuum chamber lined with an oil film. This is the solution for handling any hazardous fluid and when stringent environmental regulations have to be met.

Stainless steel self-priming pump for high flow rates QUAD

QUAD pumps have been developed to provide an economical solution to the problem of pumping liquids. They have a suction height of up to 6 m and a pressure head of up to 25 m, which makes them suitable for the most demanding applications.

The absence of valves and other complex mechanisms in motion eliminates the risk of breakage and low productivity.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

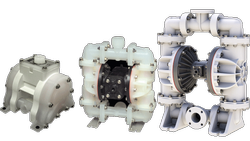

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

High Efficiency Industrial Pumps: Key Features and Benefits

Description of High Efficiency Pumps

High efficiency industrial pumps are modern pumping devices designed to ensure maximum performance and efficiency in pumping liquids or gases. Their main difference from conventional pumps is their advanced design and the use of innovative technologies that reduce energy consumption and increase the pump's efficiency.

Advantages of High Efficiency Pumps

High efficiency pumps bring many advantages, making them the best choice for industrial applications. First of all, they provide significant economic benefits by reducing operating energy costs. In addition, high-efficiency pumps have a long service life and require minimal maintenance, which reduces the cost of repairing and replacing equipment.

Applications of high-efficiency pumps in industry

High-efficiency industrial pumps are widely used in various industries, including the oil and gas, chemical, food and pharmaceutical industries. They are used to pump various liquids, including water, oil, chemical solutions and other liquids with different physicochemical properties. Their use allows you to increase the productivity and efficiency of production processes.

Choosing a high-efficiency pump

When choosing a high-efficiency pump, you need to consider a number of factors, such as performance requirements, environmental characteristics, operating conditions and budget. There are many different models and types of high-efficiency pumps, allowing you to choose the optimal solution for specific production tasks.