Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

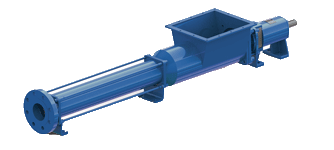

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

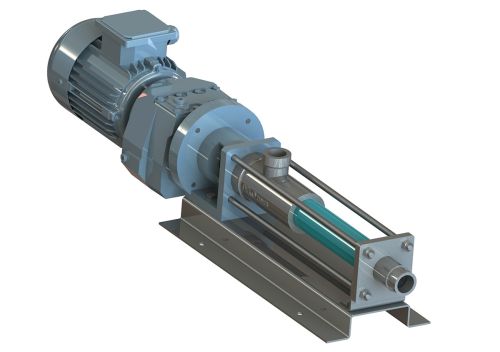

Screw dosing pump

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

10 reasons to buy screw pumps from ASCO PUMPS:

- Low maintenance of the pump during its operation

- Pumping suspensions without disturbing the structure and destroying inclusions

- Pumping of almost any liquid

- Steady flow at the pump outlet

- Proportional pumping, which makes it possible to make the pump dosing

- Ability to create high pressure

- High self-priming capacity, lifting from a depth of up to 9.5 m

- Pumping highly viscous liquids

- Wear-free pumping of liquids with abrasive particles and high dry matter content

- Simple design - easy pump maintenance, low operating costs

Articles

The last news and articles

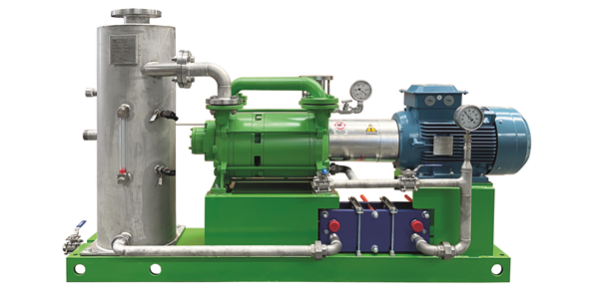

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details