High-pressure homogeniser Rannie/Gaulin

The equipment required for a homogeniser includes all components that can grind liquid particles, resulting in a homogeneous and stable product emulsion. Industrial and laboratory high-pressure homogenisers are direct-acting piston pumps equipped with a pressing unit and a homogenising valve, which can be used in various industries and improve product quality and stability.

What should a homogeniser be used for? Homogenisers are widely used in the dairy, food, healthcare, cosmetic, chemical, biotechnology and pharmaceutical industries. They can provide significant added value, improved product quality and competitive advantage. Systems can be designed and configured to offer specific product characteristics, including:

- Significantly improved product palatability

- Particle size control for more homogeneous, finer emulsions

- Reduced amount of emulsifiers and stabilisers required

- Improved binding to water

- Improved colour properties

- Homogeneous emulsions

- Creams and lotions that are easier to apply

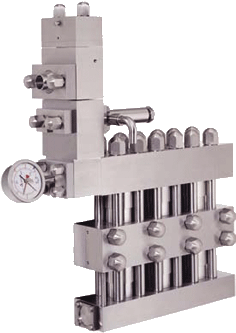

Rannie Three-Piece valve housing

Modular design consisting of a three-piece valve body and individual cylinders (3 IFI 5). The three blocks around the pump valves have a very simple and user-friendly design which, together with the individual cylinders, provide very high pressures.

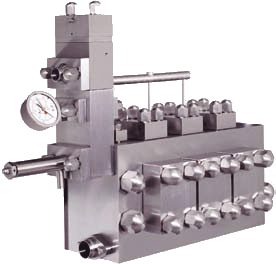

Gaulin Mono-Block valve housing

Integrated design of cylinders (3 or 5), pump valves, plunger lubrication and inlet/outlet in one unit. Access to plunger and pump valve seals via front and top covers.

Laboratory homogenisers

The laboratory homogeniser is designed for high-speed mixing, emulsifying and disintegrating liquids, suspensions and semi-solids. APV laboratory homogenisers produce the desired average particle size as well as a small spread and a uniform size distribution, i.e. exactly what you need to improve your existing products and create new ones.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 advantages of co-operating with us for the supply of industrial pumps

- High quality products

- Our company supplies industrial pumps from the world leading manufacturers. We guarantee the high quality of our products, which is confirmed by many successful projects and positive feedback from our Customers. Our pumps are highly reliable, durable and efficient, which ensures uninterrupted operation at your production facilities.

- Personal approach

- We understand the uniqueness of each order and offer customised solutions tailored specifically to the technical requirements and wishes of each customer. Our specialists are ready to provide advice, conduct technical analysis and select the most suitable type of pumping equipment.

- Service and technical support

- In addition to supplying equipment, we offer a full range of maintenance and repair services. Our qualified engineers are ready to come to the site promptly to eliminate malfunctions, which minimise downtime.

- Flexible terms of cooperation

- We strive to make cooperation with us as convenient and profitable as possible for you. In this context, we offer flexible delivery terms, including prompt order fulfilment and the ability to choose a convenient delivery method.

- Wide range of products

- Our catalogue contains a wide range of industrial pumps of various types and modifications, which allows us to meet the needs of almost any production process. From pumps for general industrial use to specialised solutions for specific industries, we have it all.

- Environmental responsibility

- We recognise the importance of environmental safety and strive to minimise our impact on the environment. The pumps we supply comply with all the latest environmental standards and requirements, enabling our customers to not only optimise their production processes but also contribute to environmental protection.

Articles

The last news and articles

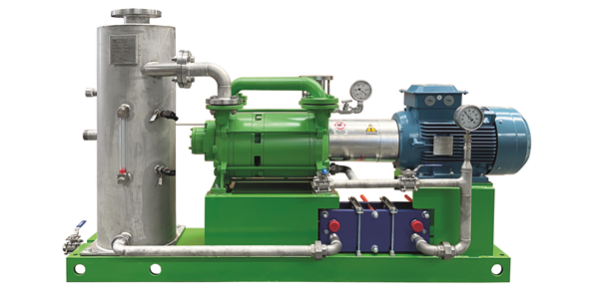

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details