Non-Metallic AOOD Pump

Metallic AOOD Pump

Pneumatic diaphragm pump for standard operating conditions are one of the most popular series on the market. They are available in a wide range of sizes (1/4" - 3") and are used to handle general-purpose liquids such as clean water, process water, mildly aggressive liquids, liquids with a moderate content of small inclusions, oil products, etc. They are often used in the ceramic, chemical and paint and varnish industries, as well as in the wastewater and utilities sectors.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

5 reasons to buy industrial diaphragm pumps from ASCO PUMPS

- All production processes are certified according to UNI EN ISO 9001/2008 standards.

- We offer our customers reliable solutions tailored to the application, operational needs and capabilities of the customer.

- All equipment is manufactured at our own plants.

- Each of the pumps we sell is thoroughly tested at the factory before being shipped to the customer. Only when our specialists are 100% sure of the integrity and performance of the equipment do they send it to you. Thus, you can be sure that the pump will serve you for a long time.

- For some of our products, preliminary design work is required, followed by installation. Our technical specialists will provide preliminary consultations and carry out the installation after the equipment has been delivered to your company. That is why we provide a guarantee for all our services.

Articles

The last news and articles

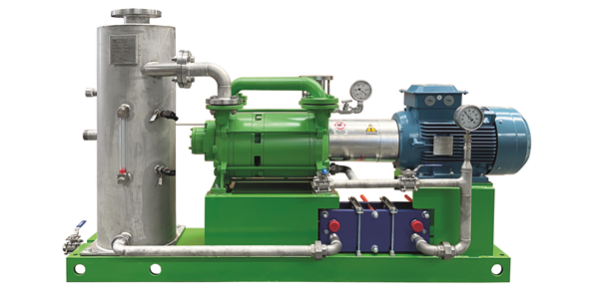

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details