Chemical Injection Packages

Chemical Injection packages are the instrument to implement a chemical treatment program in oil & gas industry (upstream and downstream), water treatment field, power generation and in any field where it is required the injection of an additive to a specific process. These units are specifically designed to dose a precise and accurate amount of a chemical into a system at a required pressure either continuously or intermittently.

Hydraulic & Wellhead Control Panels

Control cabinets (single or multifunctional) and high-pressure units are designed to control downhole safety valves, control valves, gate valves, air valves and gas lift valves. The cabinets are designed for local or remote control. The control cabinets are available in IP 65. All electrical and electronic control systems meet the requirements for operation in hazardous areas. The control method can be pneumatic, electro-hydraulic and PLC. The equipment is designed to meet the most demanding operating conditions on oil platforms, onshore, in all weather conditions.

Engineered Pump Skids

Frame mounted pumping units are efficient complete pump unit installations. The design of the unit is adapted to each specific application. Frame-mounted pumping units include: a support frame, a process vessel, pumps, instrumentation, pipework and fittings, and electrical equipment.

The units are suitable for operation in ATEX zones, as well as in other safe general industrial areas. The most common applications are: transport of anti-corrosion agents, anti-limescale agents, foam defoamers, hypochlorite injection systems, monoethylene glycol and diethylene glycol injection systems.

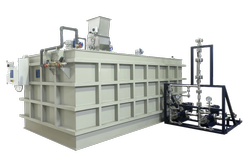

Automatic Polymer Preparation Unit

Polyelectrolytes are organic substances normally used as water solutions to remove particles (by coagulation and flocculation process) in both municipal and industrial water treatment plants. The Automatic Polyelectrolyte Preparation Units are designed and manufactured to automatically prepare polyelectrolyte solutions at a required concentration, in order to optimize the consumption of polyelectrolyte.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 advantages of co-operating with us for the supply of industrial pumps

- High quality products

- Our company supplies industrial pumps from the world leading manufacturers. We guarantee the high quality of our products, which is confirmed by many successful projects and positive feedback from our Customers. Our pumps are highly reliable, durable and efficient, which ensures uninterrupted operation at your production facilities.

- Personal approach

- We understand the uniqueness of each order and offer customised solutions tailored specifically to the technical requirements and wishes of each customer. Our specialists are ready to provide advice, conduct technical analysis and select the most suitable type of pumping equipment.

- Service and technical support

- In addition to supplying equipment, we offer a full range of maintenance and repair services. Our qualified engineers are ready to come to the site promptly to eliminate malfunctions, which minimise downtime.

- Flexible terms of cooperation

- We strive to make cooperation with us as convenient and profitable as possible for you. In this context, we offer flexible delivery terms, including prompt order fulfilment and the ability to choose a convenient delivery method.

- Wide range of products

- Our catalogue contains a wide range of industrial pumps of various types and modifications, which allows us to meet the needs of almost any production process. From pumps for general industrial use to specialised solutions for specific industries, we have it all.

- Environmental responsibility

- We recognise the importance of environmental safety and strive to minimise our impact on the environment. The pumps we supply comply with all the latest environmental standards and requirements, enabling our customers to not only optimise their production processes but also contribute to environmental protection.

Articles

The last news and articles

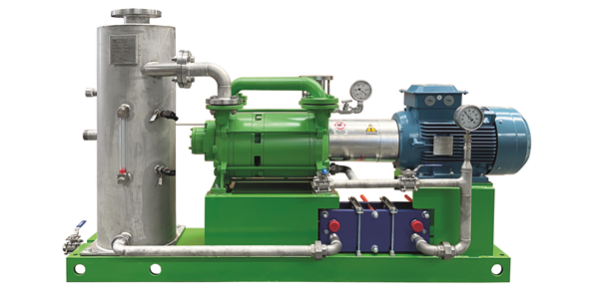

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details