Butterfly valve SV/SVS

The DELTA SV/SVS butterfly valves are manually or pneumatically operated shut-off valves. The valves are very robust and reliable and their compact design makes them ideal for almost all applications. The valve is very easy to install and maintain.

Single-seat valve SW4

When designing this valve, great care was taken to make it easy to handle, install and maintain.

Its hygienic design makes it ideal for use in the dairy, beverage and brewing industries as well as in the chemical and pharmaceutical industries.

Single-seat valve SWmini4

Hygienic universal valve in a small size. The hygienic design of the valve makes it ideal for use in the dairy, brewing, beverage, chemical and pharmaceutical industries. The valves are designed for universal use and are characterised by increased mechanical reliability and absolute ease of maintenance.

Single-seat valve MS4/MSP4

The MS4 and MSP4 aseptic single seat valve series are designed for applications in the food, beverage, dairy, pharmaceutical and chemical industries. These valves are available in shut-off, change over, and tank outlet configurations.

Double Seat Mixproof Valve DE3

Double Seal Valve Delta SD4

SD4 valves are (double seal) safe flow valves designed for safe media separation applications in the food, beverage, dairy, pharmaceutical and chemical industries. It is available as a shut-off, change-over and tank bottom valve.

Double Seat Ball Valve DKR2

Double seat ball valves APV DELTA DKR2 are proving their worth day by day in the fields of brewing, beverage technology, dairies and the food industry as well as in chemistry! The field of application of the APV DELTA DKR2 valve comprises the separation of two line sections with different fluids by two independent seals with intermediate leakage chamber and free drain to the atmosphere. They were especially developed for use in industries where the highest priority is given to the protection against the mixing of products.

Double Seal Valve SWcip4

The SWcip4 valve is a double seal valve designed especially for CIP applications. The valve replaces old-fashioned block and bleed concepts based on three butterfly valves or double butterfly valves. With two serial seat seals and a separation cavity, this double seal valve ensures that intermixing of CIP media is avoided. This valve helps to increase product safety demands in CIP systems.

AP1 - Aseptic Diaphragm Valves

The SPX FLOW AP1 diaphragm valve range offers optimum protection of the product in aseptic applications. Product safety is provided by the hermetic separation of the product chamber from the environment (atmosphere) by a flexible diaphragm shaft. The function of the valve is to shut off line sections or aseptic tanks.

Pressure Relief Valves DELTA UF / UFR

APV offers the DELTA UF/UFR pressure relief valves to protect systems against overpressure. The valve opens when the set pressure values are exceeded.

Constant Pressure Valves CPV

The CPV constant pressure diaphragm valve forms part of the pneumatically operated pressure regulating and pressure holding valves which keep process pressures constant in process technological plants of the food and beverage as well as of the pharmaceutical and chemical industries (e.g. application of separators, pasteurizers and UHT plants, fillers, etc.).

Modulating Valves RG4

The RG4 control valve is designed for continuous flow and pressure control. It is equipped with a diaphragm actuator and a positioner. It can be used in all industries. For hygienic applications, it is available with flexible flow coefficient values. For aseptic applications, the valve can be equipped with a PTFE diaphragm, stainless steel siphon or vapour barrier.

Valve Control Units CU4

The CU4 series is a portfolio of control units that allows users to safely, efficiently, and reliably process their products. Each CU4 offers advanced functionality and features at a price-competitive value. These innovative control units can be used on any pneumatically-operated SPX FLOW sanitary valve. There are several variants available depending on the valve type, controls system, and user interface.

Vacuum Valves VRA / VRAH

The valve is available in an upright design, APV VRA and a suspended design, APV VRAH. The valve opens when a vacuum of a certain pressure occurs in the tank and it closes when the vacuum has disappeared (VRA - closing by spring pressure, VRAH - closing by dead weight). The seat lifter opens the valve during the CIP process in order to clean the valve seat and the seat seal. It can also be used for remote controlled function check.

Check Valves RUF3

The RUF3 check valve is inserted into the process line where it is necessary to prevent the backflow of the medium. When the pressure is balanced, the valve starts to close under the action of the spring and remains closed when the pressure from the spring increases. It is used in any production. Prevents the backflow of fluid.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 advantages of co-operating with us for the supply of industrial pumps

- High quality products

- Our company supplies industrial pumps from the world leading manufacturers. We guarantee the high quality of our products, which is confirmed by many successful projects and positive feedback from our Customers. Our pumps are highly reliable, durable and efficient, which ensures uninterrupted operation at your production facilities.

- Personal approach

- We understand the uniqueness of each order and offer customised solutions tailored specifically to the technical requirements and wishes of each customer. Our specialists are ready to provide advice, conduct technical analysis and select the most suitable type of pumping equipment.

- Service and technical support

- In addition to supplying equipment, we offer a full range of maintenance and repair services. Our qualified engineers are ready to come to the site promptly to eliminate malfunctions, which minimise downtime.

- Flexible terms of cooperation

- We strive to make cooperation with us as convenient and profitable as possible for you. In this context, we offer flexible delivery terms, including prompt order fulfilment and the ability to choose a convenient delivery method.

- Wide range of products

- Our catalogue contains a wide range of industrial pumps of various types and modifications, which allows us to meet the needs of almost any production process. From pumps for general industrial use to specialised solutions for specific industries, we have it all.

- Environmental responsibility

- We recognise the importance of environmental safety and strive to minimise our impact on the environment. The pumps we supply comply with all the latest environmental standards and requirements, enabling our customers to not only optimise their production processes but also contribute to environmental protection.

Articles

The last news and articles

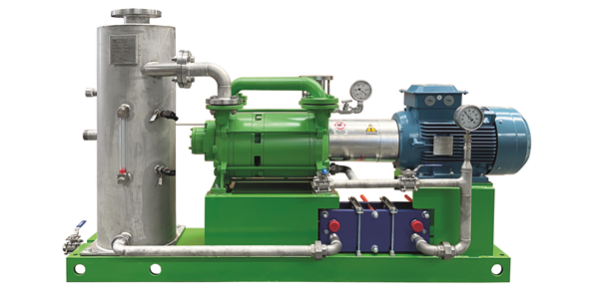

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details