Wanner Hydra-Cell Pro® pumps without seals and packings

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 advantages of co-operating with us for the supply of industrial pumps

- High quality products

- Our company supplies industrial pumps from the world leading manufacturers. We guarantee the high quality of our products, which is confirmed by many successful projects and positive feedback from our Customers. Our pumps are highly reliable, durable and efficient, which ensures uninterrupted operation at your production facilities.

- Personal approach

- We understand the uniqueness of each order and offer customised solutions tailored specifically to the technical requirements and wishes of each customer. Our specialists are ready to provide advice, conduct technical analysis and select the most suitable type of pumping equipment.

- Service and technical support

- In addition to supplying equipment, we offer a full range of maintenance and repair services. Our qualified engineers are ready to come to the site promptly to eliminate malfunctions, which minimise downtime.

- Flexible terms of cooperation

- We strive to make cooperation with us as convenient and profitable as possible for you. In this context, we offer flexible delivery terms, including prompt order fulfilment and the ability to choose a convenient delivery method.

- Wide range of products

- Our catalogue contains a wide range of industrial pumps of various types and modifications, which allows us to meet the needs of almost any production process. From pumps for general industrial use to specialised solutions for specific industries, we have it all.

- Environmental responsibility

- We recognise the importance of environmental safety and strive to minimise our impact on the environment. The pumps we supply comply with all the latest environmental standards and requirements, enabling our customers to not only optimise their production processes but also contribute to environmental protection.

Articles

The last news and articles

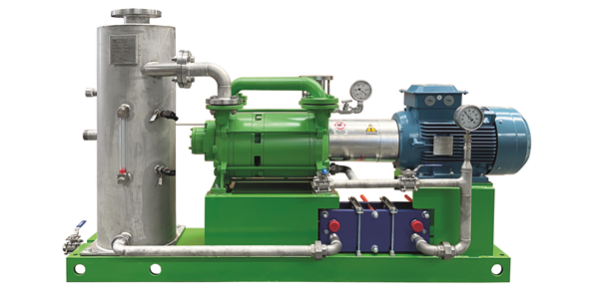

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details