Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

12 reasons to buy the peristaltic pumps from ASCO PUMPS

- 20 different sizes are available, covering flow rates from 0 to 150,000 litres per hour.

- Pumping delicate liquids with little wear and tear.

- Since only the inside of the hoses and bushings come into contact with aggressive and contaminated liquids, liquids can be pumped without the damage caused by other pumping technologies.

- Hoses are made of natural rubber NR, NBR, food grade NBR, EPDM, Hypalon, FKM, Viton

- Possibility of precise control over the volume of the supplied liquid - the device is capable of performing dosing operations of flowing substances.

- Possibility of passing solids in the pumped material, 20% of the hose identifier.

- Safe absence of liquid in the operating system - dry running is not critical.

- Seal-less design eliminates leaks, contamination and wear and tear problems associated with tightness.

- Water suction height up to 9.8 metres.

- Possibility of reverse operation of the device.

- Robust construction of ductile iron and steel construction provides the ability to create high pressure devices at the outlet - up to 15 bar.

- Low maintenance requirements for hose and boot.

Articles

The last news and articles

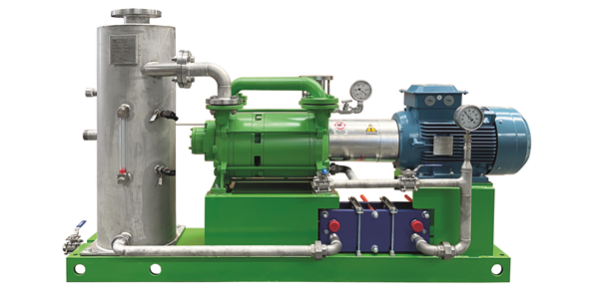

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details