Stainless steel centrifugal monoblock pumps

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Side channel self-priming stainless steel pumps X series

Side channel self-priming stainless steel pumps - MX series. It is a liquid ring pump, completely made of Stainless Steel 316, self-priming and reversible.

Stainless steel self-priming pump for high flow rates QUAD

QUAD pumps have been developed to provide an economical solution to the problem of pumping liquids. They have a suction height of up to 6 m and a pressure head of up to 25 m, which makes them suitable for the most demanding applications.

The absence of valves and other complex mechanisms in motion eliminates the risk of breakage and low productivity.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 reasons to buy hygienic centrifugal pumps from ASCO PUMPS

- High reliability. The high quality and very low internal friction make these pumps very reliable, even under severe operating conditions.

- Compactness. Very compact and lightweight pumps, which affects their performance and hydraulic efficiency.

- Reduced speed. Some models are available with a 1400 rpm motor, which provides a gentler and smoother pump movement.

- High casing thickness. High thickness steel (3 mm), which provides higher mechanical and corrosion resistance and therefore a longer service life.

- Flammable liquids. Explosion-proof motors are available for use with flammable liquids and meet ATEX standards.

- Easy dismantling. Cleaning and replacement of the mechanical seal and impeller are incredibly easy as the pump can be easily disassembled.

Articles

The last news and articles

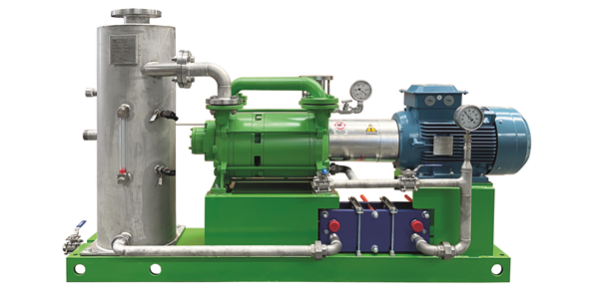

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details