Pumps for Corrosive dyes

Corrosive dye pumps are specialised equipment designed to pump aggressive and corrosive dyes. They play an important role in industry, ensuring the reliable and efficient transfer of paints and coatings to the surface of products. Industrial pumps for corrosive dyes have special characteristics that ensure resistance to aggressive media and durability under high load conditions. Choosing the right corrosive dye pump is essential to ensure high-quality coating and corrosion protection of surfaces.

TOP-13 Pumps for corrosive dyes + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

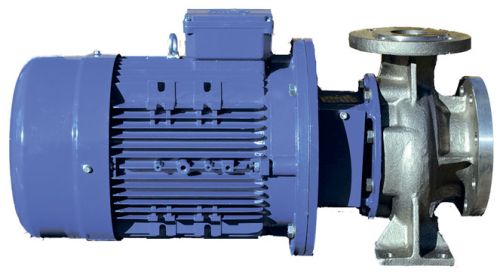

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

Stainless steel centrifugal monoblock pumps

ASCO PUMPS offers industrial pumps for the food, cosmetics, pharmaceutical, petrochemical and electroplating industries. All products are manufactured using advanced technologies by cold pressing. This production method allows the pumps to operate in difficult conditions, with an extended and guaranteed service life. The main distinguishing feature of the products is that thicker sheets of 4 mm thick AISI 304/316 stainless steel are used in the production process. This guarantees a long service life of the pumping units. Another important factor is that the corrosion resistance of parts made of stainless steel obtained by cold pressing from rolled products has been significantly increased.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

Industrial agitators

With sufficiently high power and appropriate design features, mixing devices help to achieve maximum solubility in a viscous liquid, even of solid particles of a suspension. ASCO PUMPS offers you to buy industrial mixers for your needs. This is not a standard product, so ASCO Mixers can develop mixers according to individual customer requests: using different types and diameters of impellers, with different speeds, which leads to different levels of power consumption.

Corrosive dye pumps

Corrosive dye pumps are specialized devices designed to pump aggressive paints and coatings that can be dangerous for conventional pumps. They are widely used in industry where protective coatings are required for metal structures, pipelines, equipment and other surfaces that are subject to corrosion.

Advantages of industrial pumps for corrosive dyes

Industrial pumps for corrosive dyes have several advantages over conventional pumps. They are made of particularly robust materials such as stainless steel, titanium and special polymers that provide high resistance to aggressive media and the chemicals contained in dyes.

Thanks to their specialized design, corrosive dye pumps are able to deliver stable and reliable performance even at high temperatures and pressures, making them the ideal choice for industrial paint and protective coating processes.

Choosing the right pump for corrosive dyes

When selecting a pump for corrosive dyes, several factors need to be considered, including the type of dye used, its concentration, temperature and pressure, as well as the volume and pumping rate. It is also important to pay attention to the chemical compatibility of the pump materials with the dye formulation to avoid deterioration or contamination.

Another important aspect is the performance of the pump - its ability to provide the required flow rate and pressure of the colorant during the application process. The pump must be powerful enough to ensure effective coating of surfaces without interruptions or disruptions.

Application of pumps for corrosive paints

Corrosion dye pumps are widely used in a variety of industries, including metallurgy, construction, automotive, chemicals and petrochemicals. They are used to apply anti-corrosion coatings to metal structures, cables, pipelines, as well as to paint and protect various products and materials.

Due to their efficiency and reliability, corrosion dye pumps are an important link in the industrial production process, ensuring high-quality application of protective coatings and extending the service life of equipment and facilities.