Chemically resistant pumps

Chemically resistant pumps are specialised devices designed for pumping aggressive and corrosive liquids in various industrial processes. They feature special materials of construction, such as stainless steel, polypropylene, Teflon and others, which provide high resistance to chemical agents and wear. These pumps are widely used in the chemical, oil and gas, food and other industries where reliable and safe pumping of corrosive liquids is required. When choosing a chemical resistant pump, it is necessary to consider its characteristics, such as capacity, pressure, materials of construction and compatibility with a particular environment, to ensure efficient and safe operation in aggressive chemical environments.

TOP-33 Chemically resistant + other products

VKC Sealless Mag-Drive Vertical Pumps

The vertical centrifugal pump is designed to submerge the pump in the pumped liquid so that the electric motor remains above the liquid level. The semi-submersible chemical pump uses special construction materials and technical solutions that allow it to withstand chemical attack not only from the inside but also from the outside. We offer sealed semi-submersible vertical pumps with magnetic coupling and pumps with mechanical seal for pumping sodium hydroxide and hypochlorite, sulfuric, hydrochloric, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities, etc.

Single stage liquid ring vacuum pumps AVM & AVL

The AVM and AVL series consist of single-stage liquid ring vacuum pumps designed to achieve deep vacuum. Both series have the same hydraulics but different designs.

Hoses

We offer a wide range of hoses for peristaltic pumps. Our hoses are specially designed to last longer and perform better than the competition, resulting in reduced maintenance and downtime. The type of polymer and mechanical properties of the hose are the main factors for proper pump operation. The performance of a hose is determined by its elasticity, long-term resistance to compression and its chemical compatibility with the fluid being pumped.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Liquid ring pump condenser exhausters

Liquid ring vacuum pumps are used in centralised vacuum systems and in power generation. The vacuum systems consist of exhaust ventilation units for the main condenser and filling units for the water condenser. The systems are designed for both load and hold modes.

In many cases, the pump is assisted by a first stage gas or steam ejector to improve pump performance at different condenser loads. The ASCO VACUUM team has extensive experience in geothermal applications.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

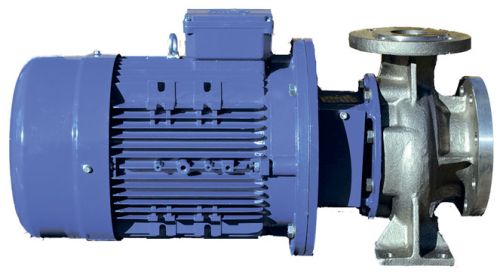

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

Vertical centrifugal pumps

You can buy centrifugal vertical single-stage pumps of the NCV series from ASCO PUMPS Ukraine. The maximum shaft length is 5 m. The standard design is designed for rotational speeds up to 2900 rpm. The radial bearings are lubricated by the pumped liquid, provided it does not contain any suspended abrasive particles. If the pumped fluid is slightly abrasive, the radial bearings are lubricated with an external special transparent grease.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

Motor speed gear pumps

Viking's motor-speed industrial pumps are designed for increased performance by using double ball bearings and a direct motor-pump arrangement. Reliable mechanical seals and gaskets eliminate leakage and extend pump life.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Side channel self-priming stainless steel pumps X series

Side channel self-priming stainless steel pumps - MX series. It is a liquid ring pump, completely made of Stainless Steel 316, self-priming and reversible.

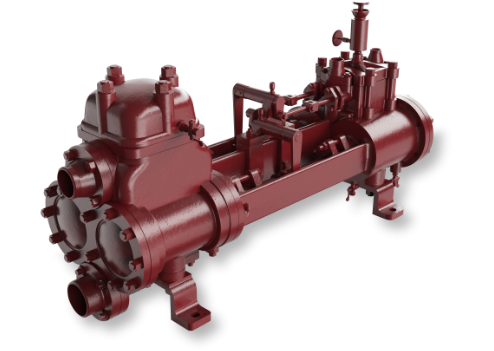

Steam driven reciprocating pumps (API 674)

Since the beginning of the last century, Peroni has been designing and manufacturing steam driven pumps used for boiler feed service, low NPSHA pump-out service and for other process applications in Petrochemical Plants and in Refineries. All Peroni steam driven pumps are reciprocating, horizontal duplex, double-acting pumps where the power is directly transmitted to the liquid end by the action of the motive fluid on the piston. The motive fluid is normally steam, but can also be air or gas.

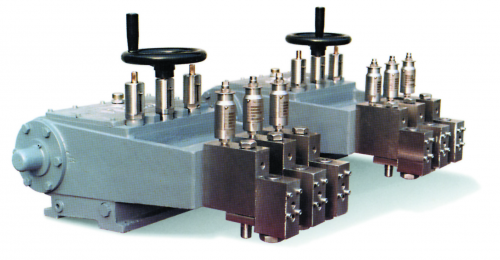

Multihead PR Plunger Pumps

The PR series presents triplex, quadruplex and quintuplex configurations for high pressure process applications, providing a compact and efficient solution for offshore applications. Its crank mechanism has an innovative design that allows multiple rams to be housed in a compact frame, ideal for space constraints.

Stainless steel self-priming pump for high flow rates QUAD

QUAD pumps have been developed to provide an economical solution to the problem of pumping liquids. They have a suction height of up to 6 m and a pressure head of up to 25 m, which makes them suitable for the most demanding applications.

The absence of valves and other complex mechanisms in motion eliminates the risk of breakage and low productivity.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

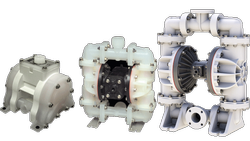

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

Drum/Barrel Pumps

FINISH THOMPSON is one of the leading manufacturers of barrel pumps and a specialist in centrifugal pumps in general. The range of drum pumps includes plastic and metal models used for emptying containers, barrels, tanks, medium-duty containers and hoppers. The range of centrifugal pumps includes stainless steel pumps, ETFE-coated process pumps, plastic pumps made of polypropylene and PVDF for aggressive, difficult chemicals.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Chemical Resistant Pumps

Chemical resistant pumps are important equipment for pumping aggressive and corrosive liquids in various industrial fields. They are specially designed using materials resistant to chemical substances, such as stainless steel, Teflon, polypropylene and others. Here is what you need to know about chemical resistant pumps:

Benefits of chemical resistant pumps

Chemical resistant pumps have a number of advantages, including:

- Corrosion resistance: The materials from which these pumps are made have high corrosion resistance, which allows them to work safely with aggressive chemical environments.

- Durability: Thanks to the use of specialized materials and engineering solutions, chemical resistant pumps have a long service life.

- Efficiency: They ensure efficient and reliable pumping of liquids even at high pressures and temperatures.

Applications of chemical resistant pumps

Chemical resistant pumps are widely used in various industries:

- Chemical industry: For pumping aggressive acids, alkalis, salt solutions and other chemical products.

- Oil and gas industry: For working with oil, oil products and chemical additives.

- Food industry: For pumping food ingredients, aggressive additives and wastewater.

- Pharmaceutical industry: For processing medical products and chemical reagents.

Choosing Chemically Resistant Pumps

When choosing a chemically resistant pump, it is important to consider the following factors:

- Liquid Type: Be sure to specify which liquids the pump will work with in order to select the appropriate material for its manufacture.

- Performance and Pressure: Make sure the pump provides the required performance and pressure for your process.

- Compatibility: Check the pump's compatibility with the chemicals and operating conditions.

- Operating Costs: Evaluate the total operating costs, including maintenance and spare parts costs.

Conclusion

Chemically resistant pumps play a key role in industrial processes where safe and reliable pumping of aggressive liquids. With proper selection and operation, they ensure efficient operation and minimize the risk of emergency situations.