Variable speed pumps

Variable speed pumps are an innovative solution in the field of pumping systems that allow you to effectively adjust the speed of the pump to your current needs. They provide the ability to automatically adjust the pump speed in response to changes in fluid flow or pressure. This enables optimum performance with minimum energy consumption, making them an attractive choice for a wide range of industrial and domestic applications. Variable speed pumps are based on advanced control technologies, such as frequency converters, which allow precise control of the pump motor speed and optimise its performance. This type of pump can be used in water supply, heating, air conditioning and industrial processes where precise and efficient control of the fluid flow is required. Due to their flexibility and energy efficiency, variable speed pumps are becoming an increasingly popular choice for reliable operation of water and other fluid transfer systems.

TOP-22 Variable speed pumps + other products

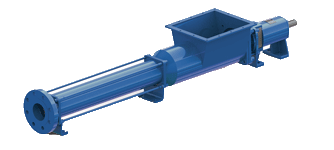

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

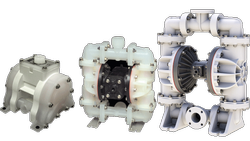

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Variable Speed Pumps: Efficient Pumping Technology

Variable speed pumps are an innovative solution in the field of pumping systems that provides flexibility and efficiency in pumping liquids. These pumps are designed to automatically adjust the speed of operation according to current needs, which allows you to significantly save energy and resources.

Advantages of industrial variable speed pumps

Industrial variable speed pumps are reliable and efficient equipment that can quickly respond to changes in load and fluid flow. They have a number of advantages:

- Energy efficiency: thanks to the ability to automatically adjust the speed, variable speed pumps consume less energy than traditional fixed speed pumps.

- Flexibility: these pumps easily adapt to different operating conditions and system needs, ensuring optimal functioning in all conditions.

- Durability: thanks to smoother starting and stopping, variable speed pumps are subjected to less mechanical stress, which increases their service life.

- Control accuracy: the ability to precisely adjust the pump speed allows you to maintain the required level of pressure and fluid flow in the system.

Variable Speed Applications in Industry

Variable Speed Applications in Industry

Variable speed pumps are widely used in various industries such as:

- Water Supply: Variable speed pumps are used to ensure continuous and efficient water supply in industrial and commercial buildings.

- Heating and Air Conditioning: They ensure optimal heat distribution and cold air production in heating and air conditioning systems.

- Industrial Processes: Variable speed pumps are used in various industrial processes where precise and efficient fluid flow control is required.

- Water Treatment: They are used to pump water in water treatment and dewatering systems where precise dosing of reagents is required.

Overall, variable speed pumps are an important technological solution for optimizing the operation of fluid pumping systems in industry and commercial enterprises. Their efficiency, flexibility and reliability make them an attractive choice for many tasks involving the pumping of liquids of various types and volumes.