Pumps for paper

Paper production pumps play an important role in ensuring the continuity of the production process. They are used to transport water, pulp and other components required to create paper pulp. Industrial papermaking pumps have special characteristics that allow them to move large volumes of liquids under high pressure efficiently. Paper production pumps need to be reliable and durable to minimise downtime and ensure production stability. In addition, they must meet environmental safety requirements to ensure that they do not harm the environment.

TOP-14 Pumps for paper + other products

Non-Metallic AOOD Pump

Metallic AOOD Pump

Pneumatic diaphragm pump for standard operating conditions are one of the most popular series on the market. They are available in a wide range of sizes (1/4" - 3") and are used to handle general-purpose liquids such as clean water, process water, mildly aggressive liquids, liquids with a moderate content of small inclusions, oil products, etc. They are often used in the ceramic, chemical and paint and varnish industries, as well as in the wastewater and utilities sectors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

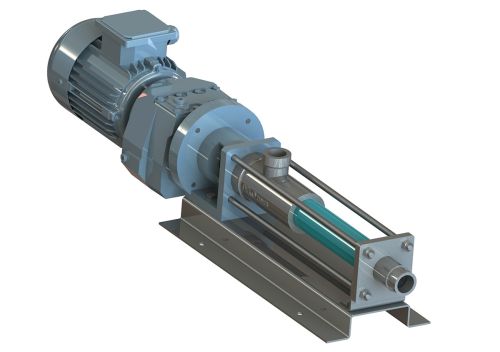

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Screw dosing pump

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

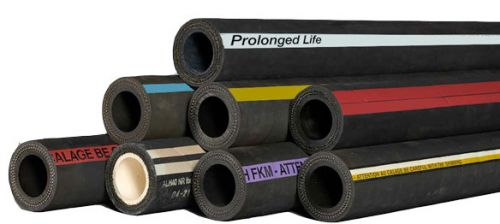

Hoses

We offer a wide range of hoses for peristaltic pumps. Our hoses are specially designed to last longer and perform better than the competition, resulting in reduced maintenance and downtime. The type of polymer and mechanical properties of the hose are the main factors for proper pump operation. The performance of a hose is determined by its elasticity, long-term resistance to compression and its chemical compatibility with the fluid being pumped.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

Pumps for paper production

Pumps for paper production

Paper pumps play a key role in the paper making process. They ensure the continuous movement of water, pulp and other components required for paper production. When selecting papermaking pumps, it is important to consider their performance, reliability and efficiency.

Applications for papermaking pumps

Industrial pumps for papermaking are used at various stages of production, including the supply of water, pulp, additives and the pumping of paper pulp. They have special design features that allow them to work effectively with aggressive media and high pressures.

Characteristics of pumps for papermaking

Pumps used in papermaking need to have certain characteristics, such as high performance, resistance to wear and corrosion, and the ability to deliver fluid under high pressure. It is also important that they are easy to maintain and have low operating costs.

Industrial pumps for paper production

Industrial papermaking pumps are specialized devices designed to withstand the high loads and demands of papermaking. They can be made of various materials, such as stainless steel, cast iron or special polymers, which provide high resistance to corrosion and abrasive materials.

Selection of pumps for paper production

Selection of pumps for paper production

When selecting industrial pumps for paper production, it is necessary to take into account the specifics of the technological process, the volume of materials to be pumped, operating conditions, and the requirements for safety and environmental friendliness. The optimal choice of pumping equipment will increase production efficiency and minimize maintenance and repair costs.

Advantages of industrial pumps for paper production

Industrial pumps for papermaking have a number of advantages, such as high performance, reliability, durability and resistance to aggressive environments. They are able to ensure continuous and stable operation of production lines, which is an important factor in ensuring the high quality of the products.

Conclusion

The paper pump is a key element of the paper production process. It is designed to transport the pulp, pulp and other components required to create the paper stock. Choosing the right pump plays an important role in ensuring the efficiency and reliability of your paper production.