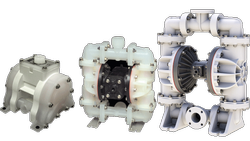

Non-Metallic AOOD Pump

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

- High level of energy saving

- Safety of the production process

- Increase in production efficiency

- Reduced downtime

- Uninterrupted operation at low temperatures

- Pumps comply with FDA standards

Articles

The last news and articles

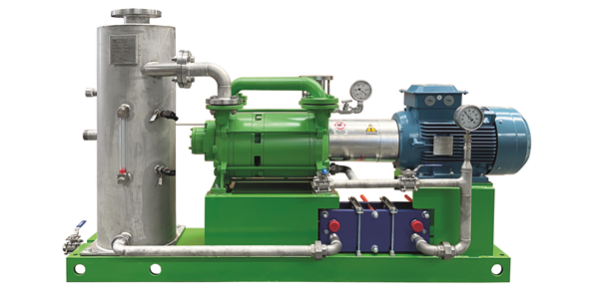

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details