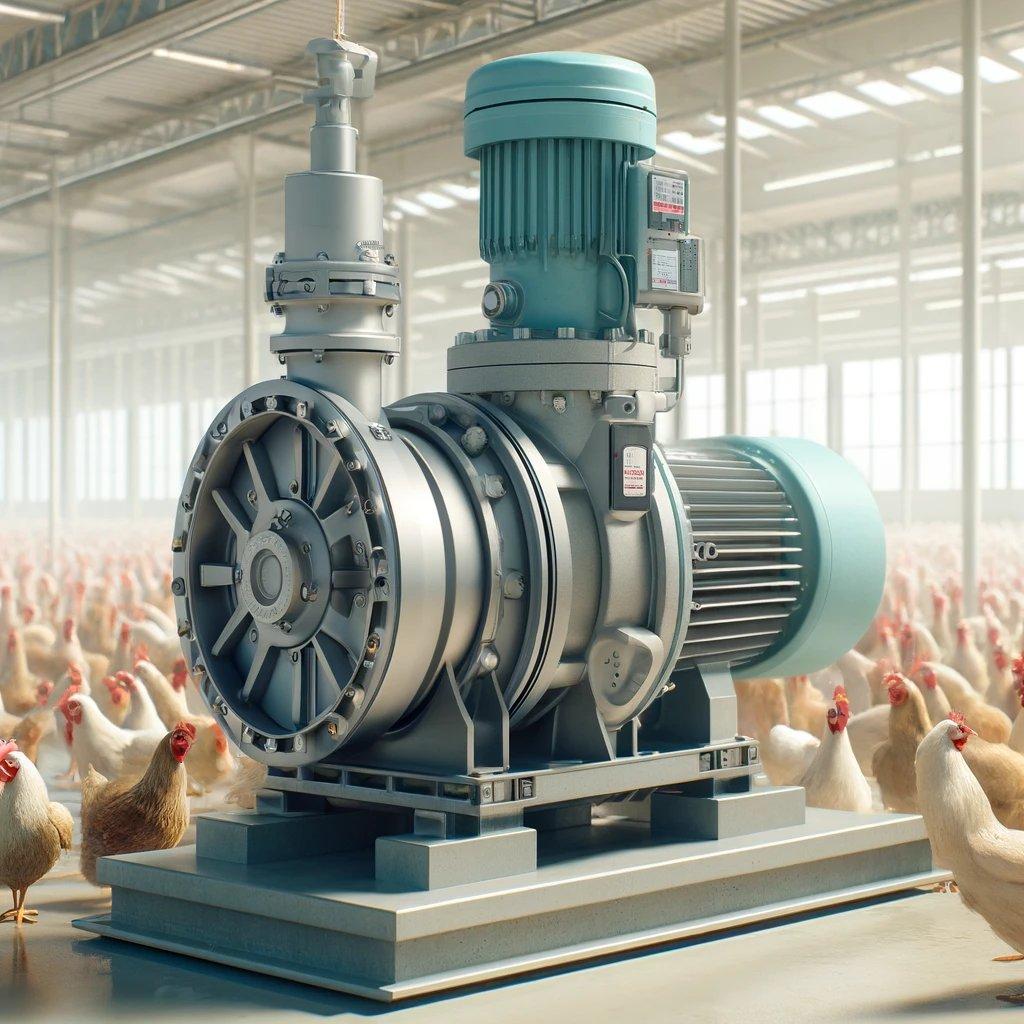

Pumps for Chicken farms

A pump for poultry farms is a specialised piece of equipment designed to efficiently pump liquids used in poultry production. It ensures reliable and safe movement of water, feed additives and other liquid components necessary to maintain the health and comfort of birds. Key characteristics of poultry farm pumps include high performance, reliability, corrosion resistance and the ability to operate in aggressive environments. They can also be equipped with special features such as self-cleaning and automatic flow control, making them the ideal choice for ensuring efficient operation of poultry farms.

TOP-9 Pumps for chicken farms + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Internal gear pumps

Our gear pump ranges are available in capacities from micro litres per hour to 350 m³/h. Maximum discharge pressures range from 8.7 to 150 bar, depending on the required capacity and the characteristics of the fluid to be pumped.

All of our gear pumps provide smooth, pulse-free, precise volumetric pumping over a wide range of temperatures and viscosities, from thin liquids to high viscosity liquids.

With a selection of wetted materials and shaft sealing options, we can offer you the right option for your application.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Stainless steel centrifugal monoblock pumps

ASCO PUMPS offers industrial pumps for the food, cosmetics, pharmaceutical, petrochemical and electroplating industries. All products are manufactured using advanced technologies by cold pressing. This production method allows the pumps to operate in difficult conditions, with an extended and guaranteed service life. The main distinguishing feature of the products is that thicker sheets of 4 mm thick AISI 304/316 stainless steel are used in the production process. This guarantees a long service life of the pumping units. Another important factor is that the corrosion resistance of parts made of stainless steel obtained by cold pressing from rolled products has been significantly increased.

Pumps for Chicken farms

Poultry farm pumps are an important part of the equipment that supports the efficient operation of poultry farms. They perform a number of key functions that are essential to ensure proper bird care and maintain optimal indoor conditions.

Performance and efficiency

Industrial pumps for poultry farms are highly productive and efficient, enabling them to pump large volumes of liquids such as water, feed and medicines quickly and efficiently. This is especially important to ensure that birds have constant access to the necessary resources and maintain their health.

Corrosion resistance and durability

Pumps for poultry farms are made of special materials that are highly resistant to corrosion and aggressive environments that are common in poultry farming. This ensures the longevity of the equipment and reduces maintenance and replacement costs.

Automation and control

Modern pumps for poultry farms are often equipped with automation and control systems that optimize fluid delivery processes and adjust flow rates according to the needs of the birds. This simplifies the work of the staff and increases the efficiency of the pumps.

Safety and sanitation

Industrial pumps for poultry farms meet high standards of safety and sanitation, which is especially important in poultry farming environments where hygiene is of utmost importance. They are easy to clean and maintain, which helps to keep the premises clean and hygienic.

A variety of models and configurations

There are many different models of poultry farm pumps on the market with different features and configurations. This allows you to choose the optimal solution depending on the specifics of the poultry farm, the volume of liquids to be pumped and the requirements for the equipment.

Support and warranty service

Purchasing pumps for poultry farms from a reliable manufacturer provides access to quality support and warranty service. This gives buyers confidence in the reliability and durability of the equipment they purchase and helps to resolve any problems quickly and efficiently.