Pumps for mining

A mining pump is a specialised type of industrial pumping equipment designed to efficiently move various types of liquids, gases and mixtures in mining conditions. These pumps are widely used in the oil, gas, mining and other industries that require reliable and powerful equipment for pumping raw materials.

TOP-12 Pumps for mining + other products

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Metallic AOOD Pump

Pneumatic diaphragm pump for standard operating conditions are one of the most popular series on the market. They are available in a wide range of sizes (1/4" - 3") and are used to handle general-purpose liquids such as clean water, process water, mildly aggressive liquids, liquids with a moderate content of small inclusions, oil products, etc. They are often used in the ceramic, chemical and paint and varnish industries, as well as in the wastewater and utilities sectors.

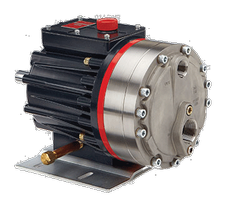

Wanner Hydra-Cell Pro® equipment

The versatility of Hydra-Cell Pro® pumps is unrivalled.

- A variety of styles and models to suit a wide range of flow rates and pressure ratings.

- Hydraulically balanced diaphragms can handle low to high viscosity liquids over the entire pump pressure range.

- A variety of construction materials are available to meet a wide range of applications and ensure optimum pump life, even when handling aggressive liquids.

- They can be equipped with SAE, ANSI or DIN flanges as well as IEC or NEMA motor mounts.

- ATEX or other certification can be provided to adapt to specific applications or to meet international standards.

- The design of the pump allows for easy change of the flow part material and the combination of different materials in one pump.

Efficient and functional - Hydra-Cell Pro® pumps can handle abrasive liquids.

- Withstands abrasive solids and solids up to 800 microns (depending on pump model) and hardness up to 9 (Mohs) without the need for fine filtration.

- Multiple diaphragms provide virtually pulsation-free flow that exceeds API 675 standards for accuracy, linearity and repeatability.

- The low shear pumping process allows delicate handling of complex structures without destruction or foaming.

Hydra-Cell Pro® pumps are environmentally friendly.

- Fluids are 100% isolated from the surrounding atmosphere.

- There is no way for toxic vapours or harmful gases to escape.

- There are no seals for volatile organic compounds (VOCs) to escape.

- Reduced energy costs for pump operation.

- Can operate dry without damaging the pump.

- Robust design allows for less than ideal operating conditions.

- No seals or gaskets to leak or replace.

- Typically operate for up to 6,000 hours between oil changes.

- Can pump acids, slurries and liquids containing up to 40% undissolved solids.

- Not dependent on the lubricant being pumped.

Top 3 Areas of Application

- Boiler feed pump.

- Steam boiler pump.

- Steam generator pump.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Dosing pumps

Valisi dosing pumps for the energy, chemical, agricultural, food and other industries have proven to be reliable equipment in more than 30 countries around the world, solving the problems of dosing liquids at industrial facilities in all industries. The wide range of products offered by ASСO PUMPS, including dosing pumps with capacities from 1 to 3200 l/h, mixers, controllers and water quality sensors, allows us to meet the needs of wastewater treatment plants, drinking water treatment plants, industrial processes, food processing, landscaping and agriculture.

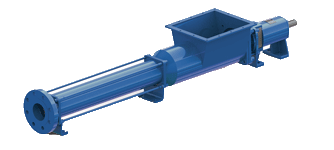

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Advantages of industrial pumps for mining

High performance and reliability

Industrial pumps for mining are designed to withstand extreme operating conditions while providing high performance and reliability in operation.

Versatility of application

Due to the variety of types and models, production pumps can be used to pump a wide range of liquids, including aggressive, viscous and high solids content.

Selection of a production pump

Key selection parameters

The selection of the right extraction pump depends on a number of critical parameters, including the type of medium to be pumped, the required capacity, pressure and operating conditions.

Types of pumps

There are different types of production pumps, including centrifugal, gear, screw and diaphragm pumps, each of which is optimized for specific operating conditions and types of applications.

Operation and maintenance of production pumps

Operating recommendations

To ensure the durability and reliability of production pumps, it is essential to follow the manufacturer's operating recommendations and perform regular maintenance.

Maintenance

Regular maintenance and timely replacement of worn-out components can prevent emergencies and extend the service life of the equipment.

Innovations in the field of mining pumps

Innovations in the field of mining pumps

Technological developments

Pumping equipment manufacturers are constantly improving their designs by introducing new technologies to increase the efficiency, reliability and safety of production pumps.

Conclusion

Mining pumps play a key role in ensuring the efficiency and safety of mining processes. Selecting the right type of pump, operating it correctly and maintaining it regularly is key to successful and productive operations in the mining industry.