Pumps for Oil refineries

Pumps for oil refineries play a key role in the oil production and refining process. Industrial pumps for oil refineries ensure efficient transportation of crude oil, its pumping and processing at all stages of production. High-quality pumps for oil refineries are able to operate under high loads and aggressive environments, ensuring reliable and uninterrupted operation of production lines. A variety of types and models of pumps for oil refineries allows you to choose the best solution for specific tasks, including pumping raw materials, refined products, as well as providing circulation and cooling of equipment. It is important to choose pumps for oil refineries that meet high quality and safety standards to ensure efficient operation of production processes and minimise the risk of accidents.

TOP-12 Pumps for oil refineries + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

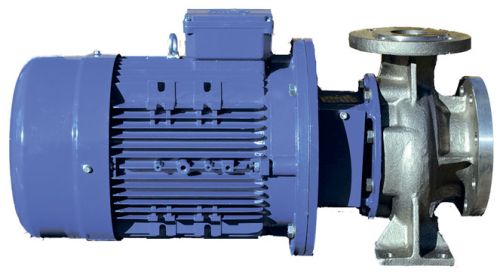

Single-stage centrifugal pumps

The product range includes chemical single-stage horizontal centrifugal pumps, horizontal monoblock centrifugal pumps, vertical single-stage centrifugal pumps, single-stage in-line centrifugal pumps and double-suction in-line pumps.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Sealless magnetic drive centrifugal pumps

ASCO PUMPS offers chemical pumps for pumping aggressive liquids such as sulfuric acid, hydrochloric and nitric acid, phosphoric acid, alkalis, wastewater with chemical impurities, solvents, salt solutions produced by FINISH THOMPSON INC. The pumps can also pump explosive liquids such as gasoline and diesel fuel.

The main products offered are horizontal and vertical centrifugal pumps with magnetic coupling, including self-priming pumps. In addition, we supply centrifugal horizontal and vertical chemical pumps with mechanical seals made of plastic, pumps for barrels, cans, and Eurocubes. The pumps are manufactured in ANSI sizes, with neodymium magnetic drives, with corrosion-resistant polypropylene and PVDF casing, and stainless steel. The range also includes pumps manufactured in accordance with EC ATEX 100 (explosion-proof version).

Magnetic coupled centrifugal pumps are the best choice of equipment when it is necessary to exclude the possibility of liquid leakage from the pump.

Filters

ASCO Filtri is a company known for its filters, specialising in the development and production of filtration solutions that are used in various industries. The products are certified and meet the highest international quality and reliability standards. We offer filtration equipment that meets the criteria of modern production tasks: modular self-cleaning designs; cartridges, bag filters; basket mesh filters; self-cleaning filters for water, hydrocarbons; coalescer filters; reverse osmosis filters; filters for water jet treatment of dirty oil. All ASCO FILTRI products are certified according to ISO 9001: 2015: 2015.

Pumps for Oil refineries

Pumps for Oil refineries

Refinery pumps are an important component of the oil industry's infrastructure. They are designed to pump oil and petroleum products at various stages of production, from extraction to sales of finished products.

Efficiency and reliability

Industrial pumps for oil refineries are highly efficient and reliable. They are capable of pumping large volumes of liquid over long distances, ensuring uninterrupted operation of production processes.

A variety of types and models

There are many different types and models of pumps for refineries on the market. These include centrifugal pumps, gear pumps, screw pumps and many more. Each type of pump has its own characteristics and is used depending on the specific operating conditions.

Specialized solutions

There are specialized solutions for different tasks in refineries. For example, chemically resistant pumps are used for pumping aggressive media and thermal pumps are used for high temperature applications. These specialized pumps ensure optimum performance and a long service life under extreme loads.

Safety and compliance with standards

Safety and compliance with standards

When choosing pumps for refineries, it is important to pay attention to their safety and compliance with quality standards. Reliable manufacturers offer certified products that meet all safety and environmental requirements.

Technical support and service

Purchasing pumps for refineries is a long-term investment. Therefore, it is important to choose a supplier that provides quality technical support and service. This will keep the pumps in good working order and maximize their service life.