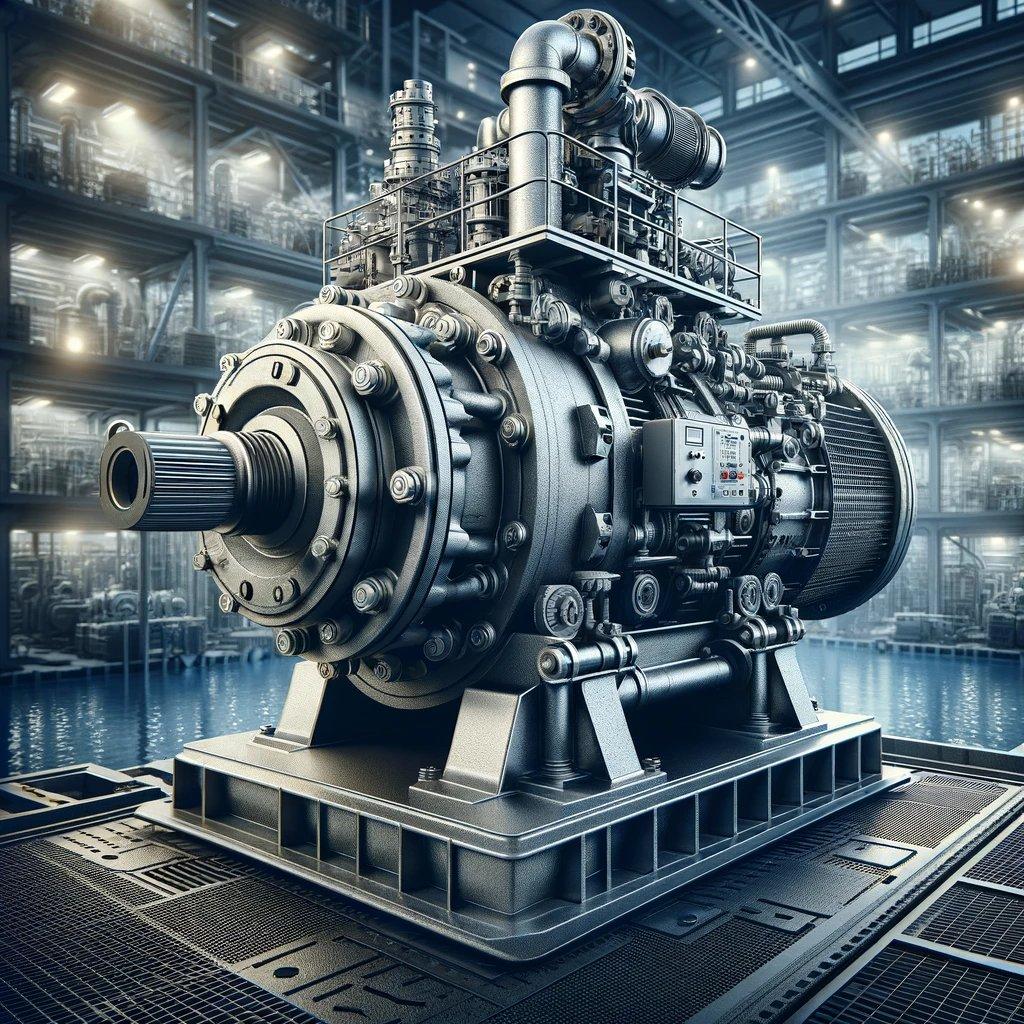

High system pressure pumps

High system pressure pumps are specialised pumping devices designed to create and maintain high pressure levels in fluid transmission systems. They have a special design and powerful motors that allow them to pump liquids under high pressure. These pumps are widely used in various industries, such as oil and gas, chemical, power and water supply, where reliable and efficient operation at high pressures is required. Their use helps to ensure stable operation of technological processes and systems, which makes them an important component in engineering systems and equipment.

TOP-17 High system pressure pumps + other products

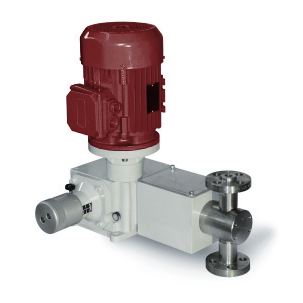

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Plate & shell heat exchangers SIGMASHELL

SIGMASHELL heat exchangers are a unique combination of the strength and high pressure capability of shell-and-tube heat exchangers with the compactness and high thermal efficiency of plate heat exchangers.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

TITANO Series

The pumps of the TITANO series are designed and manufactured according to API 674 and ASME standards and cover the range of medium power up to 600 kW.

These pumps are studied to guarantee a highly reliable service and to minimize the maintenance operations and the operating costs.

The TITANO series consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex model are used.

PTO/PQO/PSO series

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

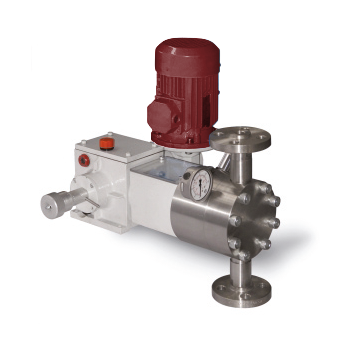

Simplex PD Plunger Pumps

The pumps in this series feature a mechanical plunger return stroke and have adjustable stroke settings from 0 to 100%, providing flexibility in operation and dosing accuracy of more than 1% over a performance range of 10 to 100%. These liquid dosing pumps maintain the required NPSH below 0.3 bar abs under standard conditions.

Simplex PD Diaphragm Pumps

The series is designed adopting hydraulically actuated double sandwich diaphragms with intermediate vacuum chamber lined with an oil film. This is the solution for handling any hazardous fluid and when stringent environmental regulations have to be met.

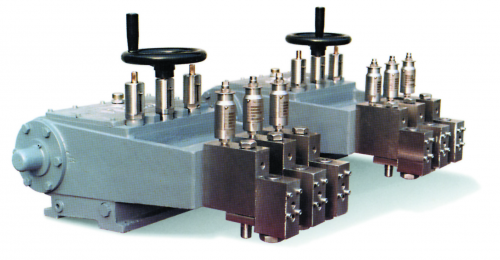

Multihead PR Plunger Pumps

The PR series presents triplex, quadruplex and quintuplex configurations for high pressure process applications, providing a compact and efficient solution for offshore applications. Its crank mechanism has an innovative design that allows multiple rams to be housed in a compact frame, ideal for space constraints.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Industrial High System Pressure Pumps: Reliability and Efficiency

Description of High System Pressure Pumps

Industrial high system pressure pumps are specialized pumping devices designed to create and maintain high pressure levels in fluid transmission systems. They have a special design and powerful motors that allow them to pump fluids under high pressure. These pumps are widely used in various industries, such as oil and gas, chemical, energy and water supply, where reliable and efficient operation at high pressures is required. Their use allows to ensure stable operation of technological processes and systems, which makes them an important component in engineering systems and equipment.

Advantages of using high system pressure pumps

The advantages of using high system pressure pumps include ensuring reliable and efficient operation of technological processes, increasing the productivity of fluid transmission systems, reducing equipment downtime and increasing the service life of pumps. Due to their power and reliability, these pumps are an integral part of industrial systems where high pressure support is required to ensure the efficient operation of production processes.

Applications of High System Pressure Pumps

High system pressure pumps are used in various industries to pump various liquids and media at high pressures. They are used in the oil and gas industry to pump crude oil, gas and water under pressure, as well as in the chemical industry to process chemical reagents and solutions. In addition, they are used in water supply and drainage systems, in cooling and heating systems, as well as in other technological processes where high pressure levels are required.

Selecting a high system pressure pump

When selecting a high system pressure pump, a number of factors should be considered, such as pressure requirements, characteristics of the pumped medium, performance, efficiency, reliability and safety. It is important to choose the optimal solution that meets the requirements of a specific production process and will ensure stable and efficient operation of the fluid transmission system.