Sanitary pumps

Sanitary pumps are specialised pumping devices designed for pumping sanitary and hygienic liquids in various industries and domestic use. They have special characteristics such as a high level of tightness, compatibility with aggressive media, ease of maintenance and ease of installation. Sanitary pumps play an important role in production processes and ensure the safety and quality of the liquids being pumped, making them an integral part of modern sanitary systems.

TOP-15 Sanitary + other products

Flex-Mix™ Instant

Flex-Mix™ Instant is a high-performance vacuum process unit suitable for use in a variety of industrial applications. It is designed to recombine, dissolve and disperse powdered products in liquids using high shear rate vacuum mixing.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

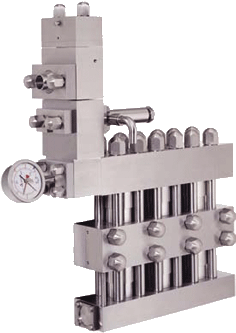

Rannie Three-Piece valve housing

Modular design consisting of a three-piece valve body and individual cylinders (3 IFI 5). The three blocks around the pump valves have a very simple and user-friendly design which, together with the individual cylinders, provide very high pressures.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Flex-Mix™ ТРМ

Flex-Mix ™ ТРМ - is a mixer used for mixing powders and liquids in the production of dairy products, sugar syrups, brines, etc.

Side channel self-priming stainless steel pumps X series

Side channel self-priming stainless steel pumps - MX series. It is a liquid ring pump, completely made of Stainless Steel 316, self-priming and reversible.

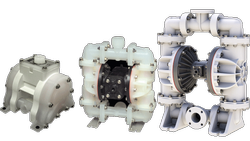

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Sanitary Pumps: Their Role and Benefits

Sanitary pumps are specialized devices designed to pump sanitary and hygienically clean liquids. They play an important role in various industries as well as in domestic use. Here are some key aspects to know about sanitary pumps:

Advantages of sanitary pumps

Industrial sanitary pumps have a number of advantages that make them indispensable in various processes:

- High level of tightness: sanitary pumps provide reliable sealing, which eliminates the penetration of harmful substances into the pumped liquid.

- Compatibility with aggressive media: they are able to work with liquids containing aggressive chemicals without loss of performance and durability.

- Ease of maintenance: sanitary pumps usually have a design that simplifies maintenance and servicing, which reduces the cost of repairs and replacement of parts.

- Convenience of installation: thanks to their compact size and ergonomic design, they are easy to install in various conditions.

- High performance: they are able to provide efficient and reliable pumping of large volumes of liquid in a short period of time.

Applications of sanitary pumps

Sanitary pumps are widely used in various industries:

- Food industry: they are used to pump food, beverages, dairy products, oils and fats.

- Pharmaceutical industry: sanitary pumps play an important role in the production processes of medicines and medical products.

- Cosmetic industry: they are used to pump cosmetics, disinfectants and other sanitary materials.

- Chemical industry: sanitary pumps are used to work with chemicals, reagents and solutions.

- Water supply and sewage: they provide pumping of water, wastewater and other liquids in water supply and sewage systems.

Choosing a sanitary pump

When choosing a sanitary pump, the following criteria must be taken into account:

- Type of pumped liquid: different pumps are designed to work with different liquids, so it is necessary to choose the appropriate type for a specific task.

- Performance and pressure: they must meet the required production parameters.

- Materials of construction: it is important to choose pumps with materials that are resistant to chemical influences and compatible with the pumped liquid.

- Reliability and durability: pumps must be reliable, have a high degree of wear protection and provide a long service life.

In general, sanitary pumps are important equipment for ensuring the hygiene and safety of pumped liquids in various industries and domestic use.