Pumps for Synthetic fibers

Synthetic fiber pumps are specialized machinery designed to efficiently pump and process raw materials in the production of synthetic fibers. They have unique characteristics that allow them to provide precise pressure and flow rates of the necessary fluids and chemicals in the fiber production process. Industrial synthetic fiber pumps are often made of special materials that are resistant to aggressive chemical influences and have a complex design that can operate at high speeds and high pressures. These pumps play a key role in the synthetic fiber production process, ensuring the stability and reliability of production lines and are important for ensuring the quality and competitiveness of the products produced.

TOP-8 Pumps for synthetic fibers + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

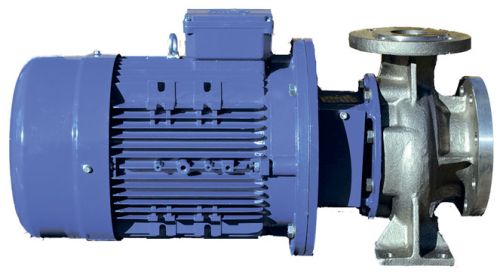

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Synthetic Fiber Pumps

Features of Synthetic Fiber Pumps

Synthetic fiber pumps play a key role in the production process of synthetic materials such as polyester, polyamide, polypropylene and other fibers. These pumps are designed to ensure the efficient pumping of chemical reagents, raw materials and solvents used in the synthesis and extrusion of fibers.

Technical requirements for industrial synthetic fiber pumps

Industrial synthetic fiber pumps must be specially designed taking into account the specifics of the synthetic material production process. They must have high reliability, stability and durability to ensure uninterrupted operation of production lines. In addition, such pumps must have chemical resistance to aggressive environments and corrosive substances that are often used in the fiber production process.

Advantages of using pumps for synthetic fibers

The use of specialized pumps for synthetic fibers provides a number of advantages for manufacturers. Firstly, it is increased production efficiency due to precise regulation of the flow rate and pressure of the pumped liquids. Secondly, it is an increase in the reliability and safety of the process due to the use of special structural materials and technical solutions capable of withstanding extreme operating conditions. Finally, it is an increase in the quality of the products produced by ensuring the stability of the parameters of the production process.

Selection of pumps for synthetic fibers

When choosing pumps for synthetic fibers, it is necessary to take into account not only the volumes of pumped liquids and the required pressure, but also the characteristics of the raw materials and reagents used. The optimal selection of pumps will ensure efficient and reliable operation of the production process, and also minimize the risks of downtime and emergencies.

As a result, industrial pumps for synthetic fibers are an integral part of the equipment for the production of modern synthetic materials, ensuring high productivity, quality and reliability of production processes.