Pumps for Meat processing

Meat processing pumps play a key role in the food industry, ensuring efficient transport and pumping of raw materials and finished products. Industrial meat processing pumps have special characteristics such as resistance to aggressive media and high performance to ensure continuous operation in production environments. They are used to pump liquid and paste-like components, including meat stock, sauces, marinades and fats. A meat processing pump must be easy to clean and maintain to meet food safety standards. It is important to choose pumps that meet sanitation and hygiene requirements, as well as being able to maintain high levels of production and product quality.

TOP-11 Pumps for meat processing + other products

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

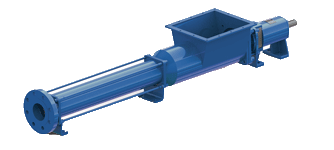

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Liquid Ring Pumps, series AVM/L, AVA, AVD/L

Liquid ring vacuum pumps are designed and manufactured for pumping air or other media contaminated with corrosive gases or containing large amounts of vapours of various liquids. The pumps are manufactured to the highest quality standards and are available in a variety of materials to suit different environmental conditions. The range of water ring vacuum pumps offers various solutions: compact monoblock versions for space-saving operation, versions with intermediate support and/or free drive shaft for a wide range of drive solutions. ASCO VACUUM water ring pumps are available as single-stage or two-stage pumps. Versions that meet explosion and fire safety requirements are also available.

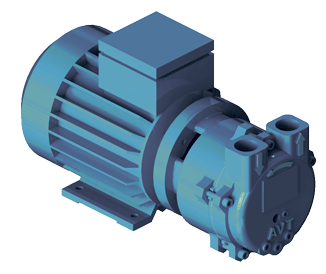

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Valves and control units

Valves are the most important components of every plant. APV offers a wide range of sanitary valves, including butterfly, single-seat and double-seat valves. Additional special valves are also available, such as control, check, constant pressure and integrated safety valves. APV valves are designed to meet the ever-increasing demands for: free product flow, flow control, safe separation of liquids, and perfect cleaning.

Pumps for meat processing

Pumps for meat processing

Meat processing pumps play an important role in the food production process. They ensure efficient pumping of raw materials and finished products, which allows food processing companies to maintain high productivity and product quality.

Industrial pumps for meat processing

Industrial pumps for meat processing are designed to meet the special requirements of this industry. They have special characteristics such as high performance, reliability and durability. These features enable them to operate under heavy load and ensure stable and trouble-free operation over a long period of time.

Meat processing - pumps

Meat processing involves a wide range of operations such as pumping meat broth, sauces, marinades, fats and other liquid and paste-like components. Pumps are used to move products along production lines, mix ingredients and package finished products.

The use of high-quality and reliable pumps for meat processing is an important step in ensuring production efficiency and product compliance with high quality and safety standards.