Pumps for research and development

Research and development pumps are specialised devices designed to support research, testing and new product development processes. They are widely used in laboratories, engineering companies and scientific institutions to move and control liquids, gases and other media. Industrial research and development pumps offer high performance, precision and reliability, making them indispensable tools for creating and testing new products and technologies. These pumps typically come with a variety of speed and pressure settings, as well as specialised features such as flow control and volume measurement. It is important to choose pumps that meet the specific needs and requirements of your project to ensure efficient operation and achieve the desired research and development results.

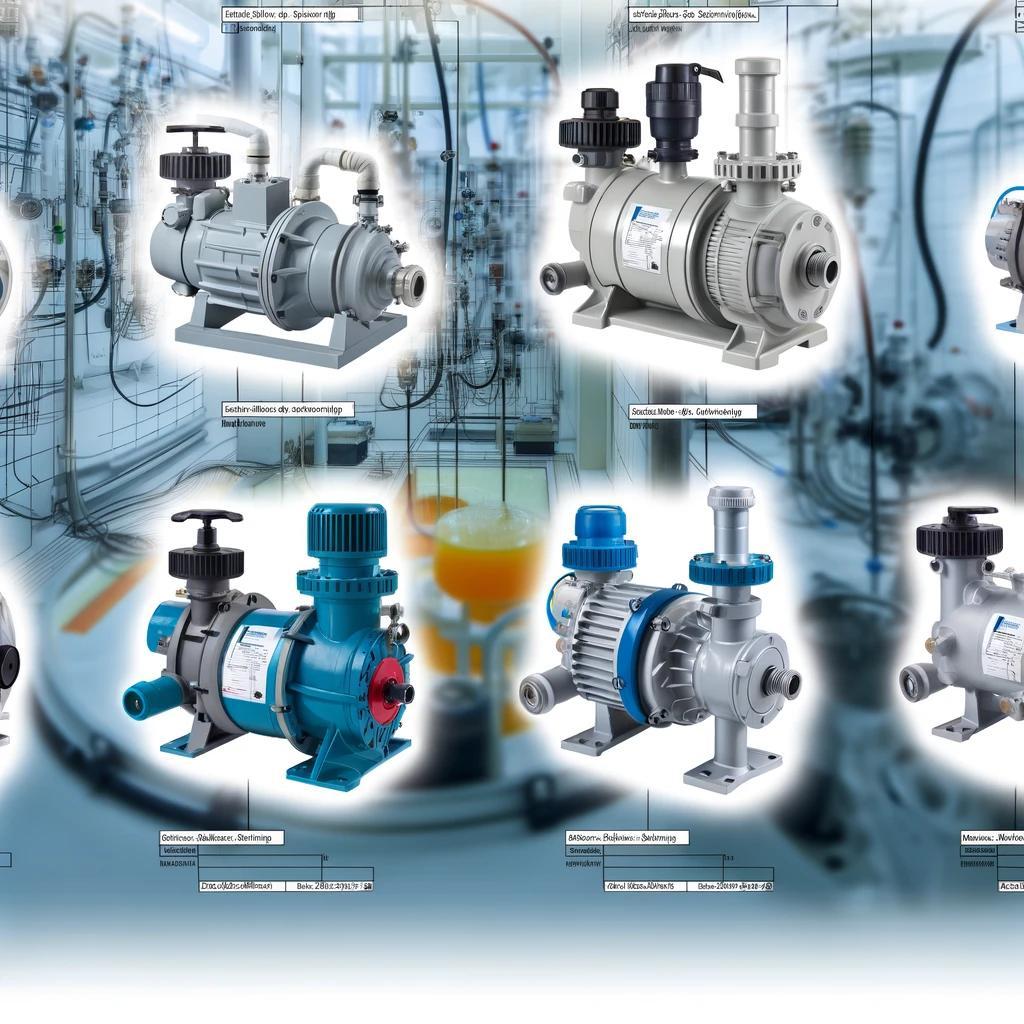

TOP-8 Pumps for research and development + other products

Single-stage centrifugal pumps

The product range includes chemical single-stage horizontal centrifugal pumps, horizontal monoblock centrifugal pumps, vertical single-stage centrifugal pumps, single-stage in-line centrifugal pumps and double-suction in-line pumps.

Non-Metallic AOOD Pump

Metallic AOOD Pump

Pneumatic diaphragm pump for standard operating conditions are one of the most popular series on the market. They are available in a wide range of sizes (1/4" - 3") and are used to handle general-purpose liquids such as clean water, process water, mildly aggressive liquids, liquids with a moderate content of small inclusions, oil products, etc. They are often used in the ceramic, chemical and paint and varnish industries, as well as in the wastewater and utilities sectors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Pumps for research and development

Research and development pumps are key components in a wide range of scientific and engineering processes. They play an important role in moving and controlling the various liquids, gases and other media required to conduct experiments and create new products and technologies.

Applications of pumps for research and development

Industrial research and development pumps are used in a variety of industries, including the chemical industry, pharmaceuticals, biotechnology, food processing, oil and gas, and many others. They are used to mix, transfer, dose and control the flow of various substances.

Features and benefits

Industrial pumps for research and development are characterized by high performance, precision and reliability. They ensure a uniform flow of media, which is especially important when conducting precise experiments and testing new formulas and recipes. Thanks to state-of-the-art technology and innovative solutions, these pumps are able to operate in a variety of conditions and deliver consistent performance.

Selecting the right pump

When selecting a pump for your R&D application, it is important to consider the specifics of your project, the required flow and pressure characteristics, and the specifics of your process environment. Different types of pumps, such as centrifugal, peristaltic, gear and diaphragm pumps, have their own unique characteristics and are designed for specific applications.

Maintenance and service

To ensure long-lasting and efficient operation of pumps, regular maintenance and service is necessary. This includes checking the condition of the pump, replacing worn parts, lubricating and cleaning. You should also monitor the pump's operating parameters and respond to any deviations in a timely manner.

Conclusion

Research and development pumps play an important role in scientific and engineering projects by ensuring the efficient movement and control of various media. When properly selected and maintained, they help you achieve the desired results and increase the productivity and reliability of your process.

.