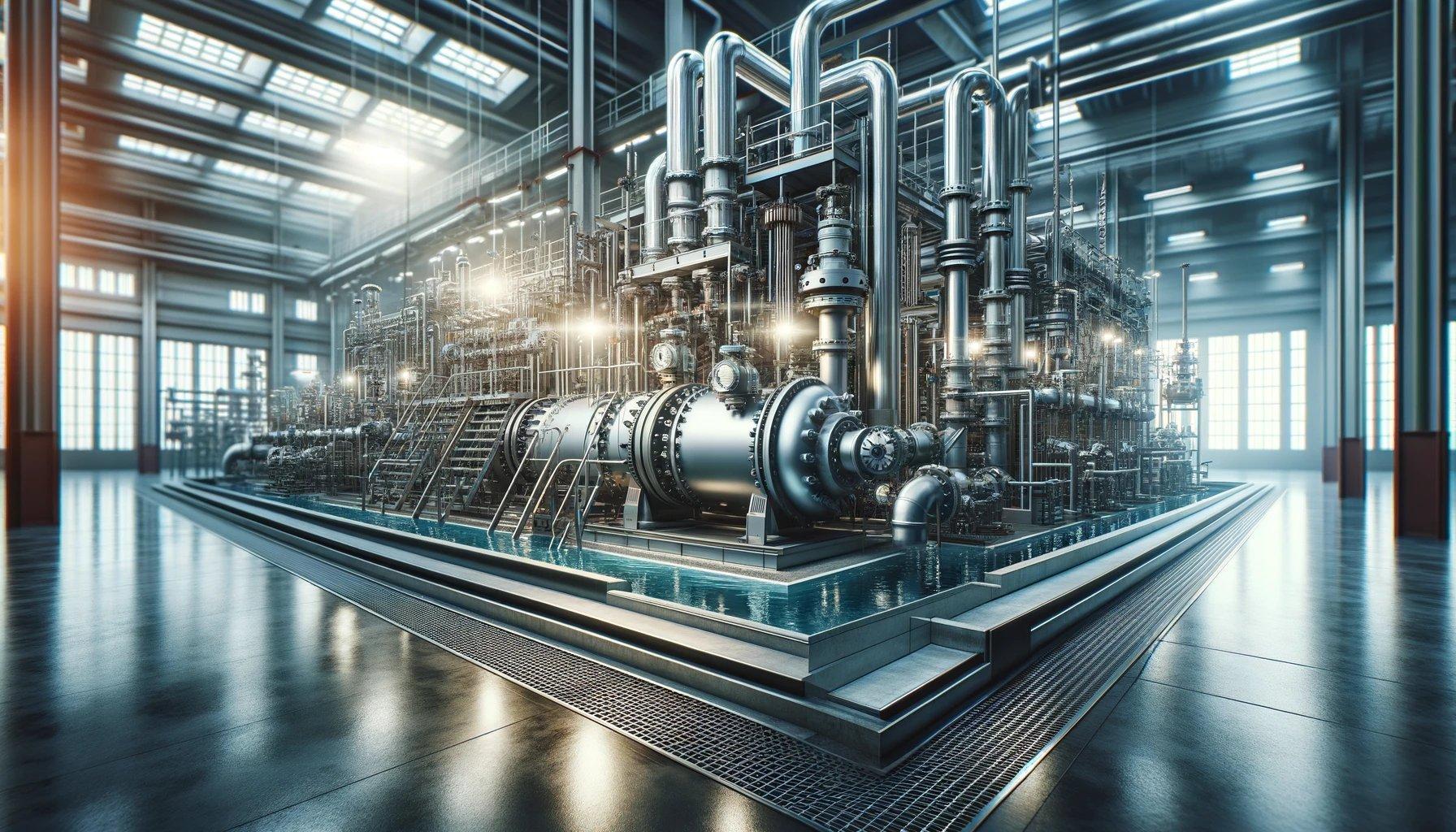

Pumps for transfer

Transfer pumps play a key role in industry, ensuring the efficient transfer of liquids and gases from one point to another. This specialised equipment is widely used in a variety of industries, including oil and gas, chemical, food and pharmaceutical. Industrial transfer pumps are highly efficient, reliable and durable, making them an integral part of many production processes. They can be equipped with various types of impellers and functionalities depending on the specific needs of the application, ensuring efficient and safe transfer of liquids and gases over long distances.

TOP-23 Pumps for transfer + other products

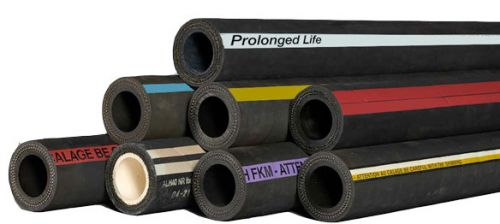

Hoses

We offer a wide range of hoses for peristaltic pumps. Our hoses are specially designed to last longer and perform better than the competition, resulting in reduced maintenance and downtime. The type of polymer and mechanical properties of the hose are the main factors for proper pump operation. The performance of a hose is determined by its elasticity, long-term resistance to compression and its chemical compatibility with the fluid being pumped.

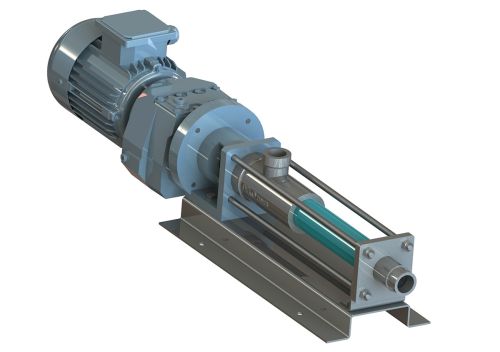

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Screw dosing pump

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

Motor speed gear pumps

Viking's motor-speed industrial pumps are designed for increased performance by using double ball bearings and a direct motor-pump arrangement. Reliable mechanical seals and gaskets eliminate leakage and extend pump life.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

PTO/PQO/PSO series

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

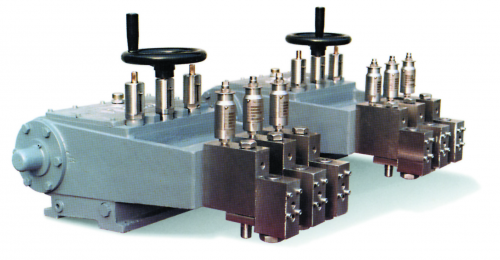

Multihead PR Plunger Pumps

The PR series presents triplex, quadruplex and quintuplex configurations for high pressure process applications, providing a compact and efficient solution for offshore applications. Its crank mechanism has an innovative design that allows multiple rams to be housed in a compact frame, ideal for space constraints.

Stainless steel self-priming pump for high flow rates QUAD

QUAD pumps have been developed to provide an economical solution to the problem of pumping liquids. They have a suction height of up to 6 m and a pressure head of up to 25 m, which makes them suitable for the most demanding applications.

The absence of valves and other complex mechanisms in motion eliminates the risk of breakage and low productivity.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Transfer Pumps

Description of Industrial Transfer Pumps

Industrial transfer pumps are important equipment in various industries, providing pumping of liquids and gases from one place to another. They are used in oil and gas, chemical, food, pharmaceutical and many other industries. These pumps are designed to handle a variety of media, including aggressive and viscous liquids, as well as corrosive environments, providing high efficiency and reliability in operation.

Advantages of using transfer pumps

One of the main advantages of industrial transfer pumps is their high performance and efficiency. They are able to handle large volumes of liquids and gases in a short time, which increases process productivity. In addition, these pumps have a reliable design and durability, which ensures their long service life and minimal maintenance costs.

Types of transfer pumps

There are many different types of transfer pumps on the market, including centrifugal, piston, peristaltic, screw and others. Each type of pump has its own characteristics and applications, which allows you to choose the most suitable option for a specific production process. For example, centrifugal pumps are well suited for pumping large volumes of liquids over long distances, while piston pumps provide high pressure and dosing accuracy.

Transfer Pump Applications

Industrial transfer pumps are used in a wide range of industries and applications. They are used for pumping raw materials, transporting products, treating wastewater, circulating fluids in cooling systems, and many other tasks. Due to their versatility and reliability, these pumps are an integral part of many production processes.

Choosing a transfer pump

When choosing a transfer pump, it is necessary to take into account a number of factors, such as the type of medium being transferred, the required volume and pressure, operating conditions, and others. It is also important to pay attention to the quality and reliability of the manufacturer to be sure of the long-term operation of the equipment. After consulting with an experienced specialist, you can choose the pump that best meets the specific needs and requirements of production.