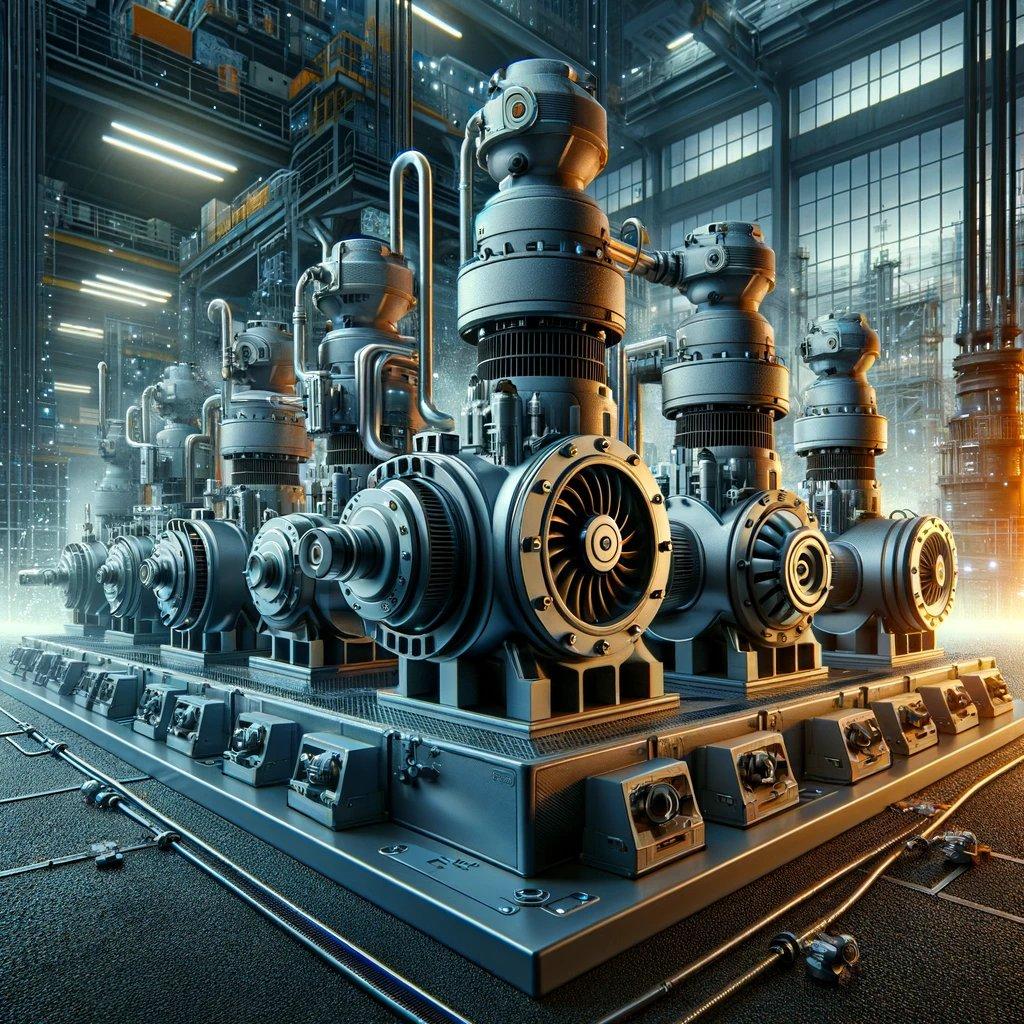

Pumps for Cooling

Cooling pumps are specialised devices designed to provide efficient cooling of various systems and equipment. They play a key role in industrial processes, the automotive and power generation industries, as well as in domestic and commercial air conditioning systems. Cooling pumps circulate a cooling liquid or gas, maintaining optimum temperature and preventing equipment from overheating. They offer a variety of features, such as performance, reliability, energy efficiency and noise levels, allowing you to choose the pump that best suits your specific requirements and operating conditions.

TOP-14 Pumps for cooling + other products

Tubular heat exchanger - ParaTube

In some cases, tubular heat exchangers are used for pasteurization and sterilization of dairy products. Unlike plate heat exchangers, these heat exchangers have no contact points in the product channel and can therefore be used to handle products whose particles are limited to a certain size. The maximum particle size depends on the pipe diameter. When operating in sterilization mode, a tube heat exchanger is less likely to need to be stopped for cleaning than a plate heat exchanger. In terms of heat transfer, a tube heat exchanger is less efficient than a plate heat exchanger.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

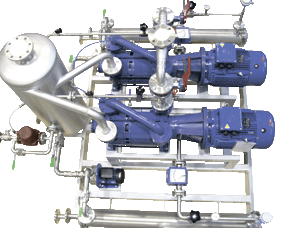

Liquid ring vacuum pump systems & centralized units

Liquid ring vacuum pump systems designed to meet most needs of vacuum of the industry. Developed with one or more pumps acting in parallel depending on the specific needs, the systems are equipped with dedicated equipment for service liquid cooling and recirculation including instrumentation and devices for control and full remote automatic operation including control panel with PLC and VFD. Units for hazardous area, on request.

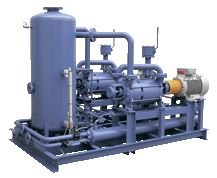

Heavy duty & API 681 liquid ring vacuum pumps & systems

Liquid ring vacuum pumps and systems meeting API 681 standards for chemical and petrochemical applications. Suitable for heavy duties, are available in different exotic materials with single or double cartridge API 682 cartridge mechanical seals. Package design standards in line with most stringent project specifications and quality requirements.

Liquid ring pump condenser exhausters

Liquid ring vacuum pumps are used in centralised vacuum systems and in power generation. The vacuum systems consist of exhaust ventilation units for the main condenser and filling units for the water condenser. The systems are designed for both load and hold modes.

In many cases, the pump is assisted by a first stage gas or steam ejector to improve pump performance at different condenser loads. The ASCO VACUUM team has extensive experience in geothermal applications.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

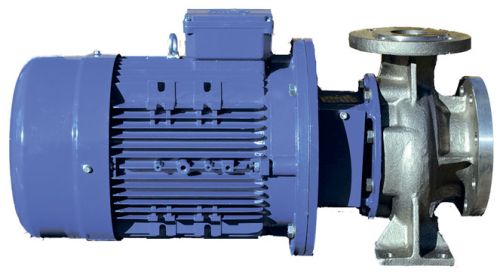

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

Side Channel Blowers

Blowers are an excellent choice for many automated projects where the application requires large volumes of clean, dry air at low pressure and vacuum. We strive to provide a solution that allows for easy installation, yet provides low operating noise and energy savings in a small, lightweight design.

Semi-welded plate heat exchangers SIGMADUAL

SIGMADUAL heat exchangers are the latest and most efficient device for transferring heat energy from a source to a destination, which can also be used for cooling purposes. Both liquids (preferably non-freezing) and gaseous substances can move in the channels of the corrugated plates as a working medium.

Plate & shell heat exchangers SIGMASHELL

SIGMASHELL heat exchangers are a unique combination of the strength and high pressure capability of shell-and-tube heat exchangers with the compactness and high thermal efficiency of plate heat exchangers.

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Cooling pumps

Efficiency and reliability

Cooling pumps play a key role in many industries, ensuring effective cooling of equipment and systems. They are characterized by high efficiency and reliability, which makes them an indispensable component of many production and commercial processes.

Variety of models

Today, there is a huge variety of cooling pumps designed for different purposes and operating conditions. From small pumps for domestic air conditioning systems to large industrial pumps for cooling heat exchangers and equipment cooling systems.

Performance and efficiency

Industrial cooling pumps are characterized by high performance and energy efficiency. They are able to provide intensive cooling with minimal energy consumption, which allows to reduce operating costs and increase production efficiency.

Pump selection

When choosing a cooling pump, it is necessary to consider not only its performance and energy efficiency, but also factors such as the type of equipment being cooled, the required cooling volume, operating conditions and available budget. It is important to choose the pump that best meets your specific needs and production conditions.

Industrial cooling pumps

Wide range of applications

Industrial cooling pumps are used in many industries, including energy, chemical production, oil and gas, food and pharmaceutical industries. They are used to cool heat exchangers, compressors, generators, engines and other equipment that requires constant cooling.

High reliability

Industrial cooling pumps are characterized by increased reliability and durability. Their design and manufacturing materials are specially designed for operation in aggressive conditions and at high loads, which ensures uninterrupted operation and a long service life.

Special technical solutions

Some industrial cooling pumps are equipped with special technical solutions, such as automatic control systems, overload and accident protection devices, pump condition monitoring systems, etc. This allows to increase the efficiency of operation and ensure the safety of equipment operation.

Cooling pump

Cooling pump

Compact dimensions

Cooling pumps have compact dimensions, which allows them to be installed in limited spaces and integrated into various cooling systems. This is especially important for residential and commercial air conditioning systems, where space is often minimized.

Easy to maintain

Cooling pumps usually have a simple design, which makes maintenance and repair easier. Due to this, they can be serviced quickly and efficiently without the need for specialized specialists.

High efficiency

Modern cooling pumps have high energy efficiency, which allows you to reduce energy consumption and operating costs. They are able to provide effective cooling with minimal electricity consumption, which is especially important for air conditioning systems in homes and offices.

Reliability and durability

Cooling pumps are made of high-quality materials that are highly resistant to corrosion and wear. This ensures reliable and durable operation of the pump for a long time without the need for replacement or repair.