Pumps for Flow Control

Flow control pumps are specialised technical devices designed to regulate or control the flow of liquid or gas in various systems and processes. They play an important role in industry, construction, agriculture and other sectors, providing accurate and efficient control of the volume and rate of media transfer. Flow control pumps can come in a variety of designs and operating principles, including centrifugal, diaphragm, gear and other types, each suitable for specific operating conditions and process requirements. It is important to choose the right pump for the specific needs and characteristics of the system to ensure reliable and efficient operation.

TOP-9 Pumps for flow control + other products

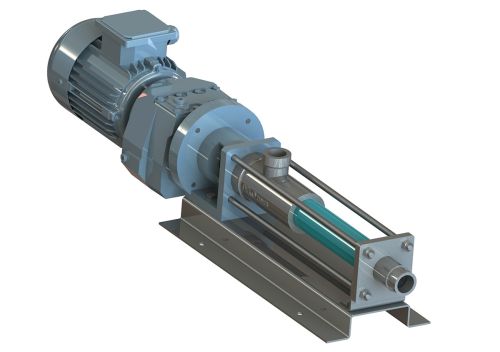

Screw dosing pump

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Flow Control Pumps

Industrial Flow Control Pumps

Flow control pumps are specialized technical devices designed to regulate or control the flow of liquids or gases in various systems and processes. They play an important role in industry, construction, agriculture and other industries, providing precise and efficient control of the volume and speed of medium transfer.

Industrial flow control pumps are designed to operate in harsh environments and have high performance and reliability. They can be used in various industries such as oil and gas, chemical, food and pharmaceutical industries, as well as in water supply and cooling systems, wastewater treatment and many others.

Flow control pump

The selection of the appropriate flow control pump depends on the specific needs and operating conditions. There is a wide range of pump types, including centrifugal, diaphragm, gear, peristaltic and others, each with its own features and advantages.

Centrifugal pumps are one of the most common types of flow control pumps. They are characterized by high performance and efficiency, can operate at various pressures and are suitable for pumping clean and dirty liquids.

Gear pumps have high dosing accuracy and are suitable for pumping viscous liquids such as lubricants and reagents. They are used in the automotive, metallurgical and food industries.

Peristaltic pumps ensure gentle and safe pumping of liquids without contact with the pump. They are widely used in the pharmaceutical and medical industries, as well as in food processing and biotechnological processes.

When choosing a pump for flow control, it is important to consider parameters such as the type of medium being pumped, pressure, flow rate, temperature, aggressiveness of the medium and tightness requirements. It is also necessary to consider the characteristics of the system in which the pump will operate, such as the length and diameter of the pipelines, the lifting height and other parameters.