Pumps for Wine

Wine pumps play an important role in the winemaking industry, providing liquid transfer at various stages of wine production, from harvesting and crushing berries to filtration and bottling. Industrial wine pumps must be specially designed to work with this beverage, taking into account its characteristics and requirements for hygiene and preservation of taste. Wine pumps must be reliable, providing precise and gentle pumping without affecting the taste and aroma of the beverage. They can have special materials that are compatible with wine, as well as unique design features such as diaphragm or peristaltic pumps that can prevent oxidation and preserve the quality of the wine. Wine pumps can be adapted to work with different types of wine and in different production conditions, from small wineries to large wineries. It is important to choose pumps that meet the specific requirements of a particular production and ensure efficient and safe wine transfer with minimal losses and risk of contamination.

TOP-9 Pumps for wine + other products

Rotary lobe pump R

The R-series pump is ideal for the type of application where pumps with metal rotors will not work effectively. When you need to strip clean your pump because the product will not wash out by using a normal CIP process such as meat processing, the R pump overcomes this problem by its simple robust design. The R pump design utilities a floating rotor without rotor nuts. Rotors are interchangeable and can only be fitted in one position due to a specially modified square shaft.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Stainless steel centrifugal monoblock pumps

ASCO PUMPS offers industrial pumps for the food, cosmetics, pharmaceutical, petrochemical and electroplating industries. All products are manufactured using advanced technologies by cold pressing. This production method allows the pumps to operate in difficult conditions, with an extended and guaranteed service life. The main distinguishing feature of the products is that thicker sheets of 4 mm thick AISI 304/316 stainless steel are used in the production process. This guarantees a long service life of the pumping units. Another important factor is that the corrosion resistance of parts made of stainless steel obtained by cold pressing from rolled products has been significantly increased.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Flexible impeller pumps

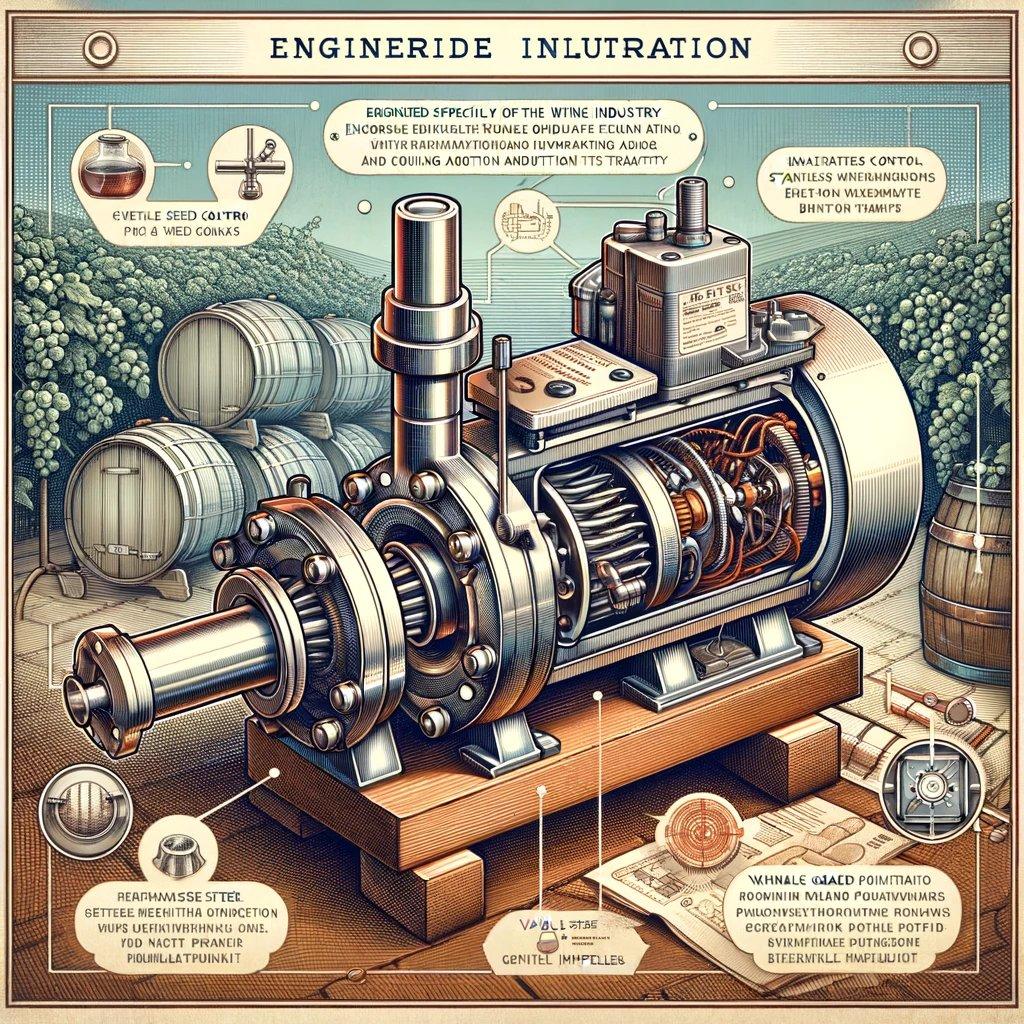

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

GUTH RA - portable agitators lateral for wineries

GUTH RA portable agitators are used for mixing, stirring and homogenising water-like or medium viscosity products. They are most commonly used in wine cellars for the production of wine and sparkling wines, but are also used in other food industries where gentle and efficient mixing is required.

The classic characteristics of RA series stirrers are their durability and efficiency. They are an important partner in the wine industry worldwide thanks to their first-class mixing results. GUTH RA portable stirrer is an unbeatable, long-term solution for any mixing problem.

Pumps for Wine

Choosing the right wine pump is crucial for an efficient production process and maintaining the quality of the beverage. Wine pumps need to have special characteristics that ensure gentle and hygienic pumping of the liquid without adversely affecting its taste and aroma.

Pumping quality

Industrial wine pumps are designed to minimize the mechanical impact on the liquid. This helps preserve the taste and aroma characteristics of the wine, preventing oxidation and loss of quality.

Maintaining hygiene

An important aspect when choosing a wine pump is its ability to ensure a high level of hygiene. Industrial wine pumps are usually made of materials that are easy to clean and disinfect, which helps to avoid contamination of wine with harmful microorganisms.

Variability

Wine pumps are available in a variety of versions to meet the needs of different types of wineries. They can be adapted to handle different types of wine and different production conditions, including small wineries and large wineries.

Durability and reliability

Purchasing an industrial wine pump is a major investment decision. Therefore, it is important to choose pumps from reliable manufacturers who guarantee the durability and reliable operation of their products. This will help to avoid unexpected production stoppages and reduce maintenance and repair costs.

Compatibility with the production process

Compatibility with the production process

A wine pump needs to be integrated into the production process and meet its requirements. This includes not only the ability to pump wine efficiently, but also compliance with the safety standards and quality requirements set by winemaking organizations and legislation.

Technical support

When choosing a wine pump, it is also important to pay attention to the availability of technical support from the manufacturer. This will help to quickly resolve any technical issues and ensure the smooth operation of the equipment.