Pumps for Water hardness

High-hardness water pumps are specialised devices designed to pump water containing large amounts of solid particles such as sand, silt, clay and other sediments efficiently. These pumps have a special design and materials that allow them to operate safely and reliably in conditions where conventional pumps may not be efficient enough or wear out quickly. Industrial pumps for high hardness water are widely used in a variety of industries, including mining, construction, agriculture, groundwater exploration, as well as for cleaning and pumping water from water sources with a high content of solid particles.

TOP-7 Pumps for water hardness + other products

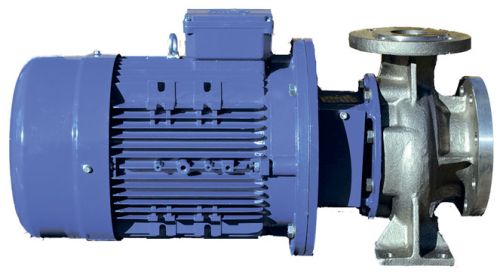

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

High Hardness Water Pumps

High Hardness Water Pumps are specialized devices designed to efficiently pump water containing a large amount of solid particles such as sand, silt, clay and other sediments. These pumps have a special design and materials that allow them to operate safely and reliably in conditions where conventional pumps may not be efficient enough or wear out quickly.

Benefits of using pumps for high hardness water:

- Wear resistance: Industrial pumps for high hardness water are usually made of special materials that are resistant to wear and corrosion, which ensures a long service life of the device.

- Effective cleaning: These pumps are able to effectively pump water containing a large number of solid particles, which allows for effective cleaning of water sources and water supply systems.

- Applications in various industries: Industrial pumps for high hardness water have found wide application in various industries, including mining, construction, agriculture and manufacturing.

- Reliability and safety: High hardness water pumps are reliable and safe devices capable of operating in extreme conditions and ensuring stable operation of the water supply system.

Choosing the Right Pump for Hard Water

Choosing the Right Pump for Hard Water

When choosing a pump for hard water, there are several key factors to consider, such as the type of water used, the volume of liquid being pumped, the required performance and pressure, and the operating conditions. It is important to choose pumps that meet the specific needs and requirements of your production or enterprise.

Based on the above, we can conclude that hard water pumps are an integral part of many industrial processes where efficient pumping of liquids with a high solids content is required. Proper selection and operation of such pumps ensure reliable and efficient operation of the water supply system, which is a key factor for successful production and ensuring safety at the enterprise.