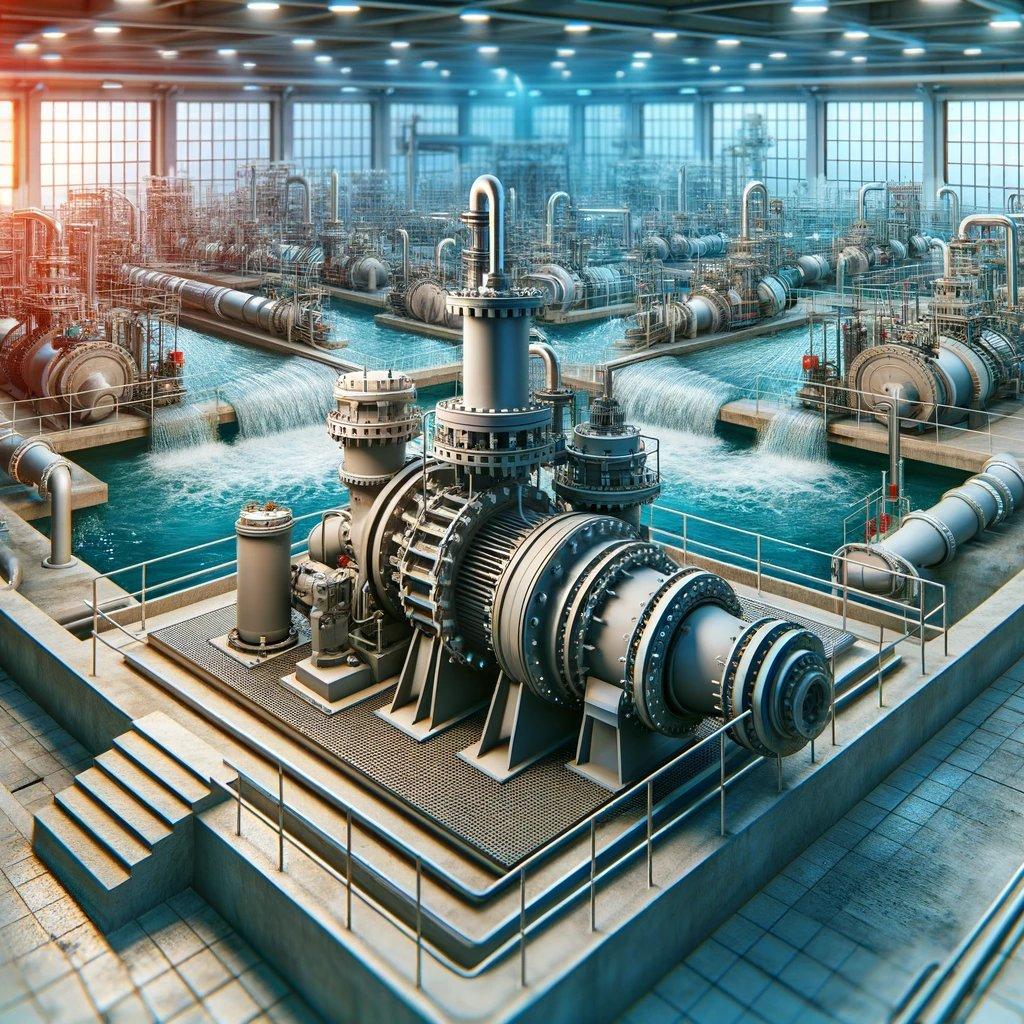

Pumps for Sewage

Sewage pumps are specialized equipment designed for pumping and treating wastewater in various industrial and municipal systems. They play a key role in removing waste and contaminated water from industrial premises, municipal networks and other facilities, ensuring effective and safe wastewater management. Industrial sewage pumps have high performance, reliability and resistance to aggressive environments, which allows them to work effectively under high loads and various chemical compositions of water. When choosing a sewage pump, it is important to take into account the specifics of the specific process, the requirements for performance and durability of the equipment, as well as comply with all relevant regulatory and environmental standards.

TOP-9 Pumps for sewage + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Stainless steel centrifugal monoblock pumps

ASCO PUMPS offers industrial pumps for the food, cosmetics, pharmaceutical, petrochemical and electroplating industries. All products are manufactured using advanced technologies by cold pressing. This production method allows the pumps to operate in difficult conditions, with an extended and guaranteed service life. The main distinguishing feature of the products is that thicker sheets of 4 mm thick AISI 304/316 stainless steel are used in the production process. This guarantees a long service life of the pumping units. Another important factor is that the corrosion resistance of parts made of stainless steel obtained by cold pressing from rolled products has been significantly increased.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

Wastewater Pumps

Effective Wastewater Management

Wastewater pumps play an important role in modern industrial and municipal systems, ensuring effective wastewater management and treatment of contaminated water. This specialized equipment is designed to pump wastewater from industrial facilities, municipal networks and other sources for further treatment and disposal.

Key features of pumps

Industrial wastewater pumps have a number of key features that make them an indispensable component in wastewater treatment and management systems. They provide high performance, overcome high pressure and effectively work with various types of contaminants, including solids, oils, fats and other substances.

Selecting pumps for specific tasks

When choosing wastewater pumps, it is important to consider a number of factors, such as the volume of pumped water, the nature of the contaminants, the required performance and the characteristics of the operating environment. Industrial pumps offer a wide range of models with different technical characteristics, which allows you to choose the optimal solution for a specific task.

Pumps for different industries

Wastewater pumps are used in many industries, including food and beverage, chemical, metallurgical, oil and gas, mining and textile. They help ensure the safety and efficiency of wastewater treatment processes in a wide variety of conditions.

Reliability and durability

Industrial sewage pumps are made of high-quality materials using advanced technologies, which ensures their high reliability and durability. They are able to work in difficult operating conditions without requiring frequent maintenance and repair, which reduces maintenance and operation costs.

Compliance with standards and regulations

When choosing sewage pumps, it is necessary to pay attention to their compliance with relevant safety and quality standards and regulations. Industrial pumps must have quality certificates and meet all requirements established by law and regulatory documents.

Environmental safety

Sewage pumps play an important role in ensuring the environmental safety of industrial and municipal facilities. They help prevent environmental pollution and preserve natural resources, ensuring effective wastewater treatment and their safe disposal.