Pumps for Irrigation water

Irrigation water pumps are specialized equipment designed to pump water from sources (rivers, lakes, reservoirs) to the irrigation system of agricultural lands. They are an integral part of modern agriculture, ensuring the efficient use of water resources for irrigation of crops. Industrial irrigation water pumps have high performance, reliability and durability, which allows them to work in difficult conditions and provide a stable supply of water to large areas of land. Irrigation water pumps can be either booster pumps, used to supply water to irrigation systems, or self-priming pumps, capable of drawing water from sources. They have different types and capacities, which allows you to choose the pump that best meets the specific needs and characteristics of the site.

TOP-6 Pumps for irrigation water + other products

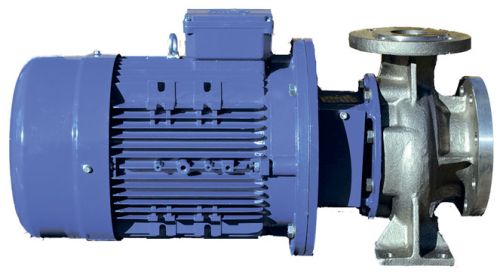

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

Irrigation water pumps: essential equipment in agriculture

Advantages of industrial irrigation water pumps

Irrigation water pumps play a key role in ensuring effective irrigation of agricultural land. They are essential equipment for pumping water from irrigation system sources, ensuring stable and uniform distribution of moisture across crops. Here are the main advantages to consider when choosing an irrigation water pump:

- High performance: industrial irrigation water pumps have a large throughput capacity, allowing them to effectively supply water to large areas of land.

- Reliability and durability: they are made of quality materials, ensuring a long service life and reliable operation even under intensive use.

- Variety of types and capacities: There are different types of irrigation water pumps on the market, which allows you to choose the optimal equipment for specific needs and characteristics of the site.

- Ease of maintenance: Most irrigation water pumps are easy to maintain and repair, which reduces operating costs and ensures smooth operation of the equipment.

Choosing the right pump for irrigation water

When choosing an irrigation water pump, there are several key parameters to consider:

- Performance: determine the required volume of water and pressure to irrigate your site.

- Pump type: choose the appropriate type of pump depending on the water source (well, river, lake) and irrigation system (drip irrigation, sprinkler system).

- Power: consider the power of the pump engine so that it meets the needs of your farm.

- Manufacturer reliability: give preference to pumps from proven manufacturers with a good reputation in the market.

Practical applications of irrigation water pumps

Irrigation water pumps are widely used in agriculture for the following purposes:

- Crop irrigation: providing plants with moisture for their growth and development.

- Starting irrigation systems: supplying water to drip irrigation systems or sprinkler systems.

- Reservoir filling: filling reservoirs on farms or pastures for livestock to drink.

- Drought protection: creating water reservoirs for use during periods of drought and lack of rainfall.

Conclusion

Irrigation pumps are an important element in agriculture, ensuring efficient use of water resources and increasing crop yields. Choosing the right pump can optimize your irrigation system, reduce watering costs, and increase the productivity of your farm.