Pumps for Cooling water

Cooling water pumps are an important component in the cooling systems of various technical devices and processes. They are designed to pump water that is used to reduce the temperature of equipment such as industrial units, compressors, engines and other machinery. These pumps play a key role in ensuring optimum equipment performance by circulating the cooling fluid. Cooling water pumps are widely used in a variety of industries, including industrial production, energy, chemicals and other areas where stable temperature conditions need to be maintained. They have special characteristics such as high performance, reliability and corrosion resistance, making them an integral part of cooling systems where the required temperature conditions for the smooth operation of equipment need to be provided efficiently and safely.

TOP-8 Pumps for cooling water + other products

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

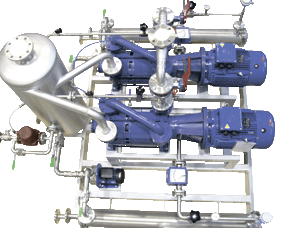

Liquid ring vacuum pump systems & centralized units

Liquid ring vacuum pump systems designed to meet most needs of vacuum of the industry. Developed with one or more pumps acting in parallel depending on the specific needs, the systems are equipped with dedicated equipment for service liquid cooling and recirculation including instrumentation and devices for control and full remote automatic operation including control panel with PLC and VFD. Units for hazardous area, on request.

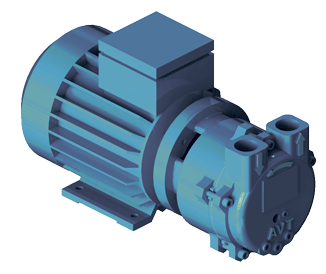

Liquid Ring Pumps, series AVM/L, AVA, AVD/L

Liquid ring vacuum pumps are designed and manufactured for pumping air or other media contaminated with corrosive gases or containing large amounts of vapours of various liquids. The pumps are manufactured to the highest quality standards and are available in a variety of materials to suit different environmental conditions. The range of water ring vacuum pumps offers various solutions: compact monoblock versions for space-saving operation, versions with intermediate support and/or free drive shaft for a wide range of drive solutions. ASCO VACUUM water ring pumps are available as single-stage or two-stage pumps. Versions that meet explosion and fire safety requirements are also available.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Cooling water pumps: ensuring efficient cooling

The benefits of using cooling water pumps

Cooling water pumps play an important role in ensuring that various technical devices that require cooling operate optimally. They are designed to pump water that is used to reduce the temperature of equipment such as industrial units, compressors, engines and other machinery. The use of cooling pumps helps to maintain stable temperature conditions, which increases the efficiency of processes and extends the service life of equipment.

Characteristics of industrial cooling water pumps

Industrial cooling water pumps have a number of special characteristics that make them an ideal choice for a variety of industrial applications. They typically offer high performance, corrosion resistance, reliability and durability. In addition, they are able to operate under high loads and extreme temperatures, making them indispensable equipment in production processes.

Applications for cooling pumps in various industries

Cooling pumps are widely used in a variety of industries, including power generation, chemical production, automotive, food and beverage, and many others. They are used to cool equipment, plants, systems and processes that need to be maintained at specific temperature conditions to ensure stable and efficient operation.

Selecting the right cooling pump for your application

When choosing a cooling pump, there are a number of factors to consider, including the volume of water to be pumped, the required head, the characteristics of the process medium and the operating conditions. It is important to choose the pump that best suits the specific needs of your production or project to ensure efficient and safe cooling of your equipment.