Pumps for Alkalis

Alkali pumps are specialised equipment designed for pumping aggressive alkaline solutions. They play a key role in various industrial processes such as detergent production, water treatment, and wastewater treatment in the chemical and pharmaceutical industries. Industrial alkali pumps are made of special chemically resistant materials such as stainless steel, Teflon, and polypropylene, which ensure reliable and safe operation in aggressive environments. This type of pump is also usually equipped with special seals and corrosion protection, which ensures a long service life and minimal maintenance costs.

TOP-8 Pumps for alkalis + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

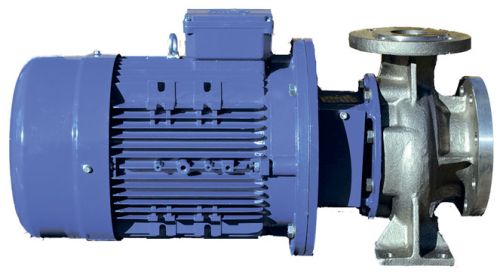

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

Drum/Barrel Pumps

FINISH THOMPSON is one of the leading manufacturers of barrel pumps and a specialist in centrifugal pumps in general. The range of drum pumps includes plastic and metal models used for emptying containers, barrels, tanks, medium-duty containers and hoppers. The range of centrifugal pumps includes stainless steel pumps, ETFE-coated process pumps, plastic pumps made of polypropylene and PVDF for aggressive, difficult chemicals.

Pumps for Alkalis

Pumps for Alkalis

Alkali pumps are specialized devices designed for pumping aggressive alkaline solutions. They are widely used in industry for handling and transporting alkaline liquids such as alkaline solutions for water cleaning, degreasing and disinfection, as well as in chemical production and pharmaceutical processes.

Chemically resistant materials

Industrial alkali pumps are made of special chemical-resistant materials such as stainless steel, Teflon, polypropylene and others. These materials provide high resistance to aggressive alkalis, preventing corrosion and ensuring a long service life.

Special seals and corrosion protection

Alkaline pumps are usually equipped with special seals and corrosion protection to ensure reliable operation in aggressive environments. This reduces the risk of leakage and damage to the pump and minimizes maintenance costs.

High performance and efficiency

Industrial alkali pumps are highly efficient and effective, enabling fast and efficient pumping of large volumes of liquid. This makes them the ideal choice for a wide range of industrial applications where large volumes of alkaline solutions need to be handled.

A variety of designs and types

There are many different designs and types of alkali pumps on the market, including centrifugal, submersible, diaphragm and other types. This allows you to choose the pump that best suits your specific needs and operating conditions.

Reliability and safety

Alkaline pumps are highly reliable and safe to operate thanks to the use of high-quality materials and components and strict quality control. This ensures stable and uninterrupted operation of the pump, even under heavy duty applications.