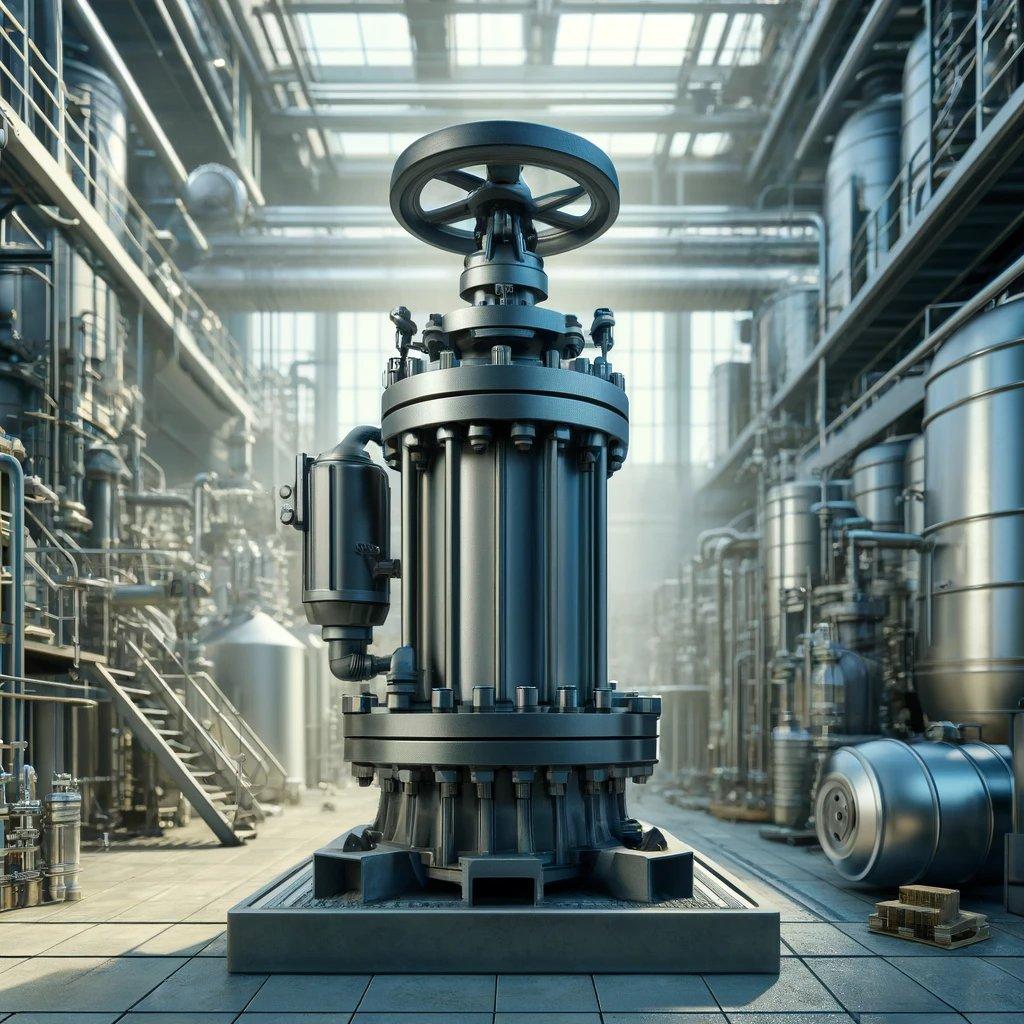

Pumps for Lime milk

Lime milk pumps are specialised devices designed for pumping highly abrasive slurries such as lime milk used in industrial gas cleaning, water treatment and cement production processes. These pumps have a reinforced design and are made of materials that are resistant to aggressive environments, which ensures a long service life and low maintenance costs. Their efficiency, reliability and ability to operate in highly abrasive environments make them an integral part of industrial processes that require the handling and transport of lime milk.

TOP-6 Pumps for lime milk + other products

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Industrial agitators

With sufficiently high power and appropriate design features, mixing devices help to achieve maximum solubility in a viscous liquid, even of solid particles of a suspension. ASCO PUMPS offers you to buy industrial mixers for your needs. This is not a standard product, so ASCO Mixers can develop mixers according to individual customer requests: using different types and diameters of impellers, with different speeds, which leads to different levels of power consumption.

Pumps for lime milk: Main characteristics

Lime milk pumps are specially designed for pumping abrasive slurries, including lime milk, which is often used in wastewater treatment, gas desulphurisation and manufacturing processes. Important characteristics of these pumps are their wear resistance, ability to cope with high viscosity and aggressive media, and reliability in operation.

Materials of construction

Lime milk pumps are usually made of materials that are resistant to corrosion and wear, such as stainless steel or special alloys. This ensures the equipment's durability under heavy use.

How it works

Industrial lime milk pumps can be centrifugal or screw pumps, depending on the performance requirements and characteristics of the pumped medium. Centrifugal pumps are suitable for high volumes and low viscosities, while screw pumps are better suited for high-viscosity and abrasive materials.

Selecting a pump for lime milk

A number of factors must be considered when selecting a lime milk pump, including capacity, maximum working pressure, abrasiveness of the medium and material requirements.

Performance and efficiency

An important parameter is the pump capacity, which must match the required pumping volume. You should also pay attention to the energy efficiency of the equipment, which helps to reduce operating costs.

Wear resistance

Wear resistance is a key factor for pumps handling abrasive media. You should choose pumps with a reinforced design and materials that can withstand high loads.

Maintenance and support

Regular maintenance of lime milk pumps helps to extend their service life and prevent unexpected production stoppages. When choosing equipment, it is important to consider the availability of spare parts and professional support from the manufacturer.

Spare parts and service

Ensuring the availability of quality spare parts and service guarantees the reliability of pumps and reduces the risk of production downtime.

Conclusion

The choice of a lime milk pump requires a thorough analysis of its characteristics and operating conditions. Industrial lime milk pumps need to be reliable, durable and efficient to ensure the smooth running of production processes.