Pumps for Ferric chloride

Ferrous chloride pumps are specialised devices designed to pump this chemical. Ferrous chlorides, such as ferric chloride(III) or ferric chloride(II), are often used in various manufacturing processes, including steel production, paints and varnishes, pharmaceuticals, and many others. Ferrous chloride pumps must be specially designed and manufactured to ensure safe and efficient pumping of this substance, taking into account its chemical properties, viscosity and temperature. These pumps are used in a variety of industrial sectors where ferrous chloride is required to be handled or transported during the production process.

TOP-8 Pumps for ferric chloride + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

Pumps for Ferric chloride

Ferric chloride (FeCl₃) is a highly corrosive and acidic liquid used in water treatment, PCB etching, and other industrial applications. When selecting a pump for ferric chloride, you must consider chemical resistance, compatibility, and reliability. Here are the best types of pumps for handling ferric chloride.

Ferrous chloride pumps are specialized devices designed to pump this chemical. Ferrous chlorides, such as ferric chloride(III) or ferric chloride(II), are often used in various manufacturing processes, including steel production, paints and varnishes, pharmaceuticals, and many others. Ferrous chloride pumps must be specially designed and manufactured to ensure safe and efficient pumping of this substance, taking into account its chemical properties, viscosity and temperature. These pumps are used in a variety of industrial sectors where ferrous chloride is required to be handled or transported during the production process.

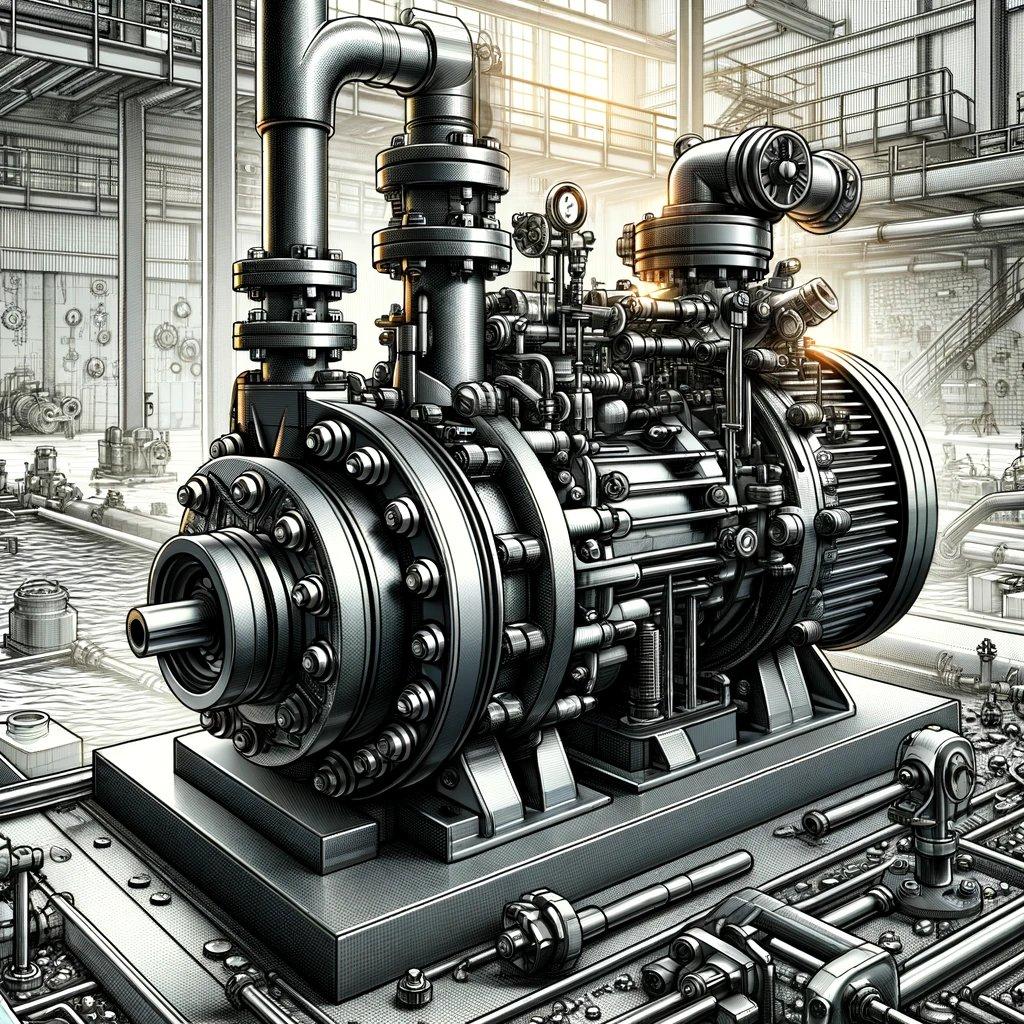

Industrial pumps for ferrous chloride

Industrial ferric chloride pumps are designed for use in the most demanding industrial environments. They provide reliable and efficient operation when pumping ferrous chloride in large volumes and at high temperatures. These pumps have special design features that enable them to handle aggressive media and provide a high level of safety and reliability.

Ferrous chloride pump

Ferrous chloride pump

The ferrous chloride pump is a key equipment in the production process that requires high performance and stable operation. It must have special characteristics to ensure efficient pumping of ferrous chloride, while minimizing wear and ensuring a long service life. These pumps can be made of various materials such as stainless steel or special alloys to ensure resistance to aggressive chemicals.

Key Considerations for Pumping Ferric Chloride

- Material Compatibility: Avoid metals like stainless steel and cast iron, as FeCl₃ is highly corrosive. Use PP, PVDF, PTFE, or FRP.

- Seal-Less Designs: Choose diaphragm or mag-drive pumps to prevent leaks.

- Self-Priming Capability: If needed, AODD and peristaltic pumps are best.

- Flow and Pressure Requirements: Match the pump specifications to your system needs.