Pumps for Hygienic liquids

Hygienic fluid pumps are specialised equipment designed to efficiently pump liquid media used for hygienic purposes, such as soaps, shampoos, shower gels and other cleaning products. These pumps feature special designs and materials to ensure the safety and hygiene of the fluids being pumped, maintaining their quality and preventing contamination. They play a key role in the production and dispensing of hygienic products in both industrial and domestic applications. Hygienic liquid pumps provide reliable and convenient dispensing of personal care products, making them an essential part of equipment for manufacturing plants and households.

TOP-7 Pumps for hygienic liquids + other products

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

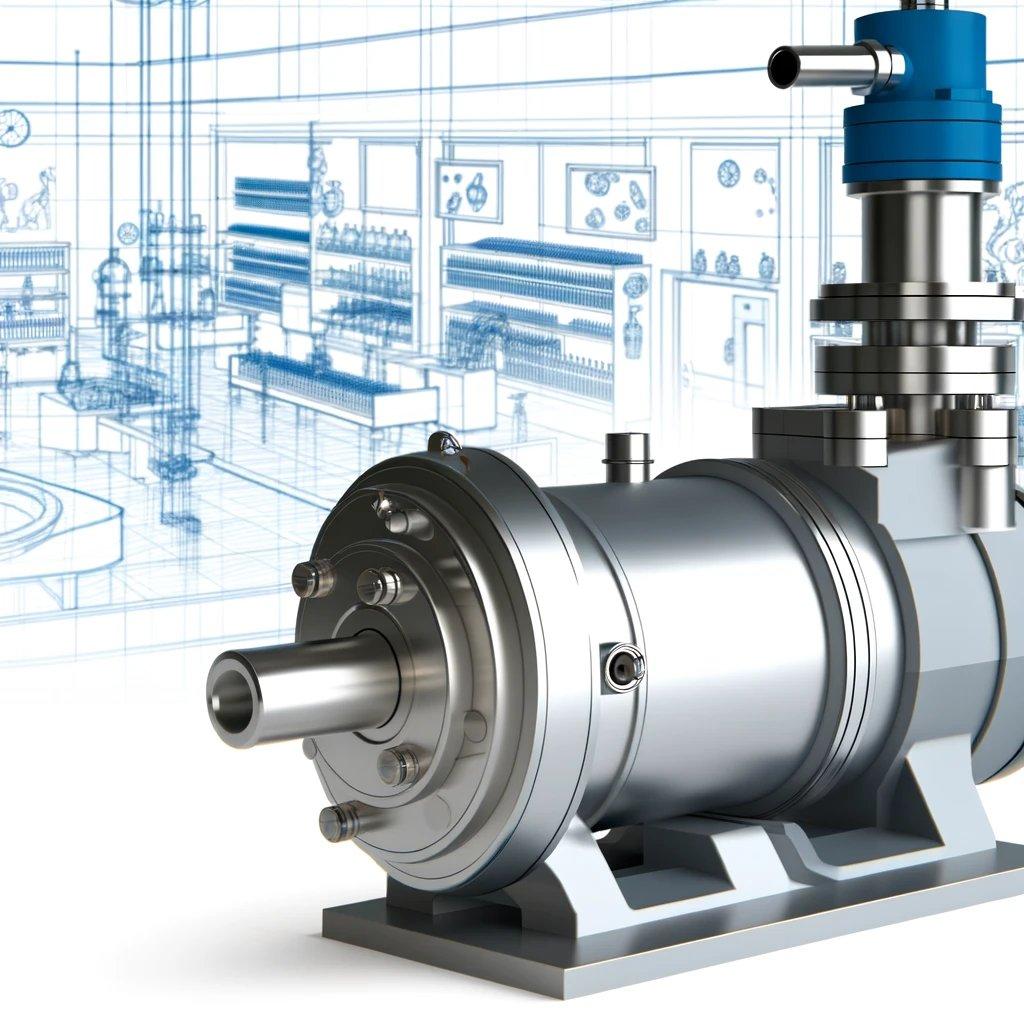

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Stainless steel centrifugal monoblock pumps

ASCO PUMPS offers industrial pumps for the food, cosmetics, pharmaceutical, petrochemical and electroplating industries. All products are manufactured using advanced technologies by cold pressing. This production method allows the pumps to operate in difficult conditions, with an extended and guaranteed service life. The main distinguishing feature of the products is that thicker sheets of 4 mm thick AISI 304/316 stainless steel are used in the production process. This guarantees a long service life of the pumping units. Another important factor is that the corrosion resistance of parts made of stainless steel obtained by cold pressing from rolled products has been significantly increased.

Pumps for hygienic liquids: safe and easy to use

Advantages of industrial hygienic liquid pumps

Hygienic liquid pumps are specialized equipment that plays an important role in the production and dispensing of hygienic products. They offer a number of advantages:

- Safety: Industrial pumps for hygienic liquids are designed to meet high safety standards, which guarantees the safety and quality of the liquids being pumped.

- Precise dispensing: they provide accurate dosing of hygiene products such as soaps, shampoos, shower gels and others, which improves production quality and increases customer satisfaction.

- Ease of use: Hygienic liquid pumps are easy to maintain and have a simple design, making them convenient to operate and maintain.

- Efficiency: thanks to special technologies and materials, they provide high efficiency in pumping liquids, which reduces losses and increases the productivity of production processes.

Key features of pumps for hygienic liquids

Hygienic liquid pumps have a number of unique features:

- Special materials: they are made from materials that are resistant to chemicals, which ensures the safety and security of the liquids being pumped.

- Variety of models: there are many different models of hygienic liquid pumps, which allows you to choose the best solution for your specific needs and conditions of use.

- Reliability: they have a high degree of reliability and durability, which guarantees uninterrupted operation for a long time.

Application of pumps for hygienic liquids

Hygienic liquid pumps are widely used in a variety of applications, including:

- Industrial production: they are used for dosing and pumping hygiene products on production lines.

- Healthcare facilities: This type of pump is used to transfer medical liquids such as antiseptics and disinfectants.

- Public places: they are installed in public toilets, bathrooms and other places where access to hygiene products is required

Conclusion

Hygiene liquid pumps are reliable and efficient equipment that play an important role in the production and use of hygiene products. Their benefits include safety, accurate dosing, ease of use and high efficiency, making them an essential component in hygiene and personal care.