Pumps for Bitumen

Bitumen pumps are specialised devices designed to pump highly viscous liquids such as bitumen and asphalt mixtures. They are used in road construction, as well as in the production and transportation of bituminous materials. Industrial bitumen pumps have a special design that ensures high reliability and efficiency at high temperatures and in conditions of high fluid viscosity. These pumps play an important role in the production and distribution of bitumen, ensuring continuous and safe pumping of materials at construction sites and industrial enterprises.

TOP-5 Pumps for bitumen + other products

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

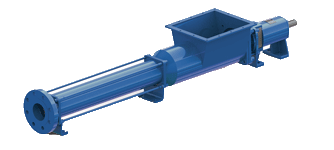

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Pumps for Bitumen

Bitumen pumps are specialized devices designed to pump highly viscous liquids such as bitumen and asphalt mixtures. These pumps play an important role in the bitumen production and distribution process, ensuring continuous and safe pumping of materials at construction sites and industrial enterprises.

Features of industrial bitumen pumps

Industrial bitumen pumps have a special design for handling highly viscous and aggressive liquids. They typically have reinforced casings and gaskets that are resistant to the chemical components of bitumen, as well as special seals that ensure tightness and prevent material leakage. This allows the pumps to operate efficiently even at high temperatures and in conditions of high fluid viscosity.

Application of bitumen pumps

Bitumen pumps are widely used in various industries, including road construction, oil refining, asphalt concrete production, and others. They are used for pumping bitumen from one tank to another, for loading bitumen into bitumen boilers, and for supplying bitumen mixtures to road surfaces. Industrial bitumen pumps provide high performance and reliability, which makes them essential equipment at construction sites and industrial enterprises engaged in the production and processing of bitumen.

Choosing the right pump for bitumen

Choosing the right pump for bitumen

When choosing a bitumen pump, it is necessary to take into account not only its performance and technical characteristics, but also the specifics of a particular production process or construction site. It is important to take into account the operating conditions, characteristics of the pumped material, leakage and safety requirements, as well as the possibility of maintenance and repair. With the right selection and operation of bitumen pumps, you can ensure the efficient functioning of the production process and minimize the risk of accidents.