Pumps for oil fats and mayonnaise

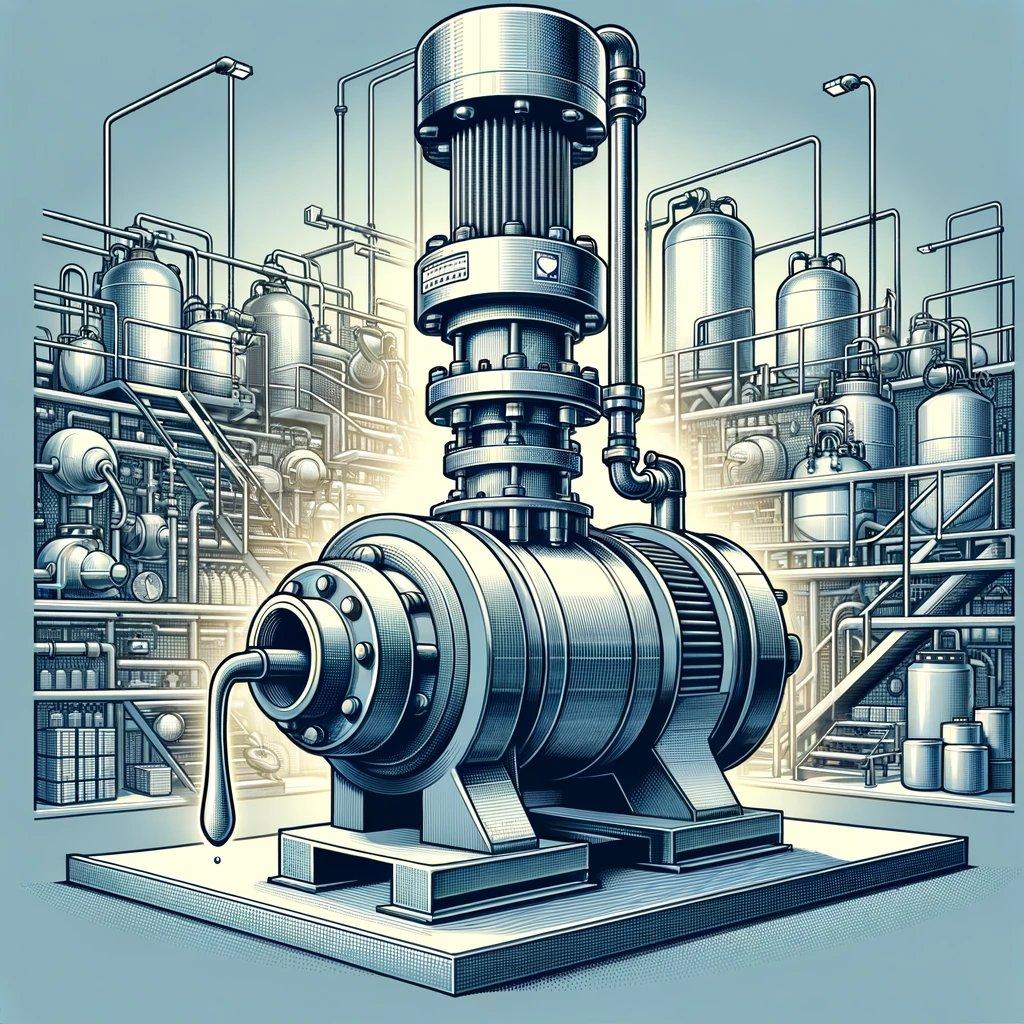

In the industrial food production market, the pumps for oil and mayonnaise production play an important role in the process of pumping and mixing various ingredients. These pumps ensure the efficient and safe transfer of oily and viscous products, such as vegetable oils and mayonnaise, from one production step to the next. Industrial pumps for oil and mayonnaise have special design features and materials that make them resistant to aggressive environments and ensure high hygiene in contact with food. Such pumps are widely used in the food industry to ensure continuous production and high quality of the final product.

TOP-13 Pumps for oil fats and mayonnaise + other products

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

APV sanitary pumps

When it comes to new developments, the range of products on the market such as hygienic pumps, you will not find a better supplier than APV SPX FLOW. Years of intensive development and product improvement have made it possible to offer a complete range of hygienic pumps to meet any process requirements in various fields such as dairy technology, brewing and beverage production, pharmaceutical and chemical industries.

APV pumps reduce production costs, create a quieter workplace, increase the reliability of the production process and ensure a higher quality of the final product. The range includes positive displacement pumps, high-performance centrifugal pumps and self-priming pumps.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Mixing and blending

APV offers a wide range of mixers and blenders for use in the dairy, food, beverage and personal care industries. These include agitators, batch mixers and continuous mixers. In addition to single mixers, APV has developed a range of modular units that can provide a high level of flexibility and efficiency for the modern production line.

APV's latest technology offers mixers that meet the specific requirements of each application, as well as provide the flexibility to process a wide range of products. The Flex-Mix™ liquiverter is a typical example of this type of plant, which allows manufacturers to respond quickly to market demand.

High-pressure homogeniser Rannie/Gaulin

The equipment required for a homogeniser includes all components that can grind liquid particles, resulting in a homogeneous and stable product emulsion. Industrial and laboratory high-pressure homogenisers are direct-acting piston pumps equipped with a pressing unit and a homogenising valve, which can be used in various industries and improve product quality and stability.

What should a homogeniser be used for? Homogenisers are widely used in the dairy, food, healthcare, cosmetic, chemical, biotechnology and pharmaceutical industries. They can provide significant added value, improved product quality and competitive advantage. Systems can be designed and configured to offer specific product characteristics, including:

- Significantly improved product palatability

- Particle size control for more homogeneous, finer emulsions

- Reduced amount of emulsifiers and stabilisers required

- Improved binding to water

- Improved colour properties

- Homogeneous emulsions

- Creams and lotions that are easier to apply

Peristaltic volumetric pumps

Peristaltic pumps, or hose pumps, are a type of positive displacement pump. The main advantage of peristaltic pumps is that nothing but the tube/hose comes into contact with the liquid. Since only the inner opening of the hose is in contact with the liquid, there is no risk of contamination of the pump.

Progressive cavity pumps

ASCO PUMPS offers standard and hygienic screw pumps, as well as spare parts such as rotors, stators and other components. The pumps are widely used in the paper and pulp industry, agricultural sector, oil and gas, paint and varnish, mining, chemical, food, explosives, artificial fibres, construction materials, wine and many other industrial sectors.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Industrial agitators

With sufficiently high power and appropriate design features, mixing devices help to achieve maximum solubility in a viscous liquid, even of solid particles of a suspension. ASCO PUMPS offers you to buy industrial mixers for your needs. This is not a standard product, so ASCO Mixers can develop mixers according to individual customer requests: using different types and diameters of impellers, with different speeds, which leads to different levels of power consumption.

Filters

ASCO Filtri is a company known for its filters, specialising in the development and production of filtration solutions that are used in various industries. The products are certified and meet the highest international quality and reliability standards. We offer filtration equipment that meets the criteria of modern production tasks: modular self-cleaning designs; cartridges, bag filters; basket mesh filters; self-cleaning filters for water, hydrocarbons; coalescer filters; reverse osmosis filters; filters for water jet treatment of dirty oil. All ASCO FILTRI products are certified according to ISO 9001: 2015: 2015.

Pumps for oil fats and mayonnaise

Pumps for oil fats and mayonnaise

In the industrial food production market, oil and mayonnaise pumps play an important role in the process of pumping and mixing various ingredients. These pumps ensure the efficient and safe transfer of oily and viscous products, such as vegetable oils and mayonnaise, from one production step to the next.

High efficiency and reliability

They are capable of processing products with different consistencies, while maintaining their performance throughout the production process.

Specialized design solutions

These pumps have specialized design solutions that allow them to work efficiently with oily fats and mayonnaise. They have unique characteristics such as high flow rates, self-cleaning capability and wear resistance.

Wide range of applications

Industrial pumps for oil fats and mayonnaise can be used in a variety of food processing industries, including the production of sauces, confectionery, dairy products, and many other products. They help ensure high quality of the final product and optimize production processes.

Compliance with safety and hygiene standards

Industrial oil and mayonnaise pumps meet strict safety and hygiene standards. They are made of special materials that ensure food safety and quality and are easy to clean and disinfect after use.

Pumps are essential equipment for food production, requiring accurate and reliable pumping of oily and viscous formulations. They effectively cope with this task, ensuring continuous operation of production lines and high quality of the final product.

Pumps are essential equipment for food production, requiring accurate and reliable pumping of oily and viscous formulations. They effectively cope with this task, ensuring continuous operation of production lines and high quality of the final product.

Advantages of use

Fat and mayonnaise pumps have a number of advantages, including high performance, reliability, ease of maintenance and long service life. They can handle products of different consistencies and ensure consistent quality throughout the production process.

Finding the right solution

When choosing an oil fats and mayonnaise pump, it is important to take into account the specifics of the production process, performance requirements and characteristics of the products being pumped. The manufacturer will be able to offer an optimal solution that meets all the requirements of the production.