Pumps for Maritime

Today, marine pumps play an important role in various aspects of maritime operations. They are used to pump water, fuel, oil and other liquids on ships, as well as in ports and marine stations. Industrial pumps for the maritime sector must be reliable, efficient and adapted to work in aggressive marine conditions. Such pumps ensure the continuous operation of ships and marine infrastructure facilities, maintaining the safety and efficiency of marine operations. When choosing pumps for the marine sector, it is important to consider the parameters of the environment, the type of fluid being transported, performance, energy efficiency and safety requirements. Reliable marine pumps help optimize ship and port operations, ensuring cost-effective and safe maritime transportation.

TOP-13 Pumps for maritime + other products

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Internal gear pumps

Our gear pump ranges are available in capacities from micro litres per hour to 350 m³/h. Maximum discharge pressures range from 8.7 to 150 bar, depending on the required capacity and the characteristics of the fluid to be pumped.

All of our gear pumps provide smooth, pulse-free, precise volumetric pumping over a wide range of temperatures and viscosities, from thin liquids to high viscosity liquids.

With a selection of wetted materials and shaft sealing options, we can offer you the right option for your application.

Sealless magnetic drive centrifugal pumps

ASCO PUMPS offers chemical pumps for pumping aggressive liquids such as sulfuric acid, hydrochloric and nitric acid, phosphoric acid, alkalis, wastewater with chemical impurities, solvents, salt solutions produced by FINISH THOMPSON INC. The pumps can also pump explosive liquids such as gasoline and diesel fuel.

The main products offered are horizontal and vertical centrifugal pumps with magnetic coupling, including self-priming pumps. In addition, we supply centrifugal horizontal and vertical chemical pumps with mechanical seals made of plastic, pumps for barrels, cans, and Eurocubes. The pumps are manufactured in ANSI sizes, with neodymium magnetic drives, with corrosion-resistant polypropylene and PVDF casing, and stainless steel. The range also includes pumps manufactured in accordance with EC ATEX 100 (explosion-proof version).

Magnetic coupled centrifugal pumps are the best choice of equipment when it is necessary to exclude the possibility of liquid leakage from the pump.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

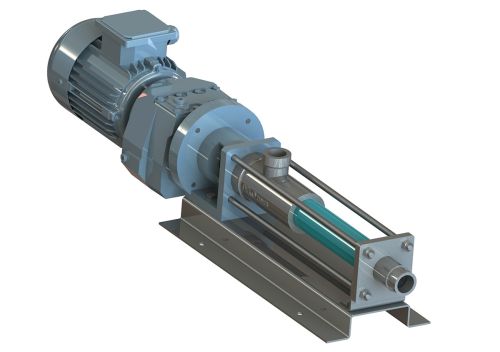

Screw dosing pump

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Sanitary plate heat exchangers

Plate heat exchangers for hygienic applications are designed for efficient heating and cooling of mechanically sensitive products in processes with high hygiene requirements. Such heat exchangers consist of a set of stainless steel plates combined into a single structure. This design can consist of several plate packs that make up separate sections in which different processing stages are carried out, such as primary heating, main heating and cooling. The heating medium is hot water, and the cooling medium is cold water, ice water or propylene glycol, depending on the required outlet temperature of the product.

Pumps for Maritime

Pumps for Maritime

Marine pumps play an important role in various aspects of marine operations. They are used for pumping liquids, controlling cooling systems, supplying fuel and other technical purposes on ships, floating facilities and shore-based structures. These pumps ensure the efficient and safe operation of marine systems and structures in a variety of environments.

Application of industrial pumps for the marine sector

Industrial pumps for the marine sector are widely used in shipbuilding, offshore oil and gas industry, seaports and offshore platforms. They ensure the reliable operation of ballast pump systems, engine cooling systems, fire extinguishing systems, water supply systems, and drainage systems. In addition, they are needed to ensure the transportation and pumping of various liquids at offshore facilities.

Characteristics of marine pumps

Marine pumps must be corrosion-resistant, efficient in salt water, and able to withstand high pressures and temperatures. They must also meet international safety and environmental sustainability standards. When selecting marine pumps, it is important to consider their type, performance, materials, overall dimensions, and the ability to integrate into existing marine systems.

Benefits of using marine pumps

The use of specialized marine pumps ensures the safety and reliability of marine operations, reduces the risk of accidents and mitigates environmental damage. These pumps help to optimize ship and offshore facility maintenance processes, increase the efficiency and productivity of marine operations, and reduce operating costs.