Pumps for Rinsing

Flushing pumps are specialised devices designed to effectively clean various surfaces, equipment and systems from dirt and residues. They provide a powerful flow of water or other liquids under high pressure, which makes it easy to remove dirt, dust, oils, rust and other contaminants. Industrial flushing pumps are often used in the automotive industry, construction, metalworking and other industries that require high-quality cleaning of surfaces before further processing or operation. They are characterised by high performance, reliability and durability, making them essential equipment in industrial and commercial applications.

TOP-14 Pumps for rinsing + other products

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

Centrifugal axial flow pump entirely made of SS

The EL series pumps are designed for pumping liquids containing solid particles. The axial impeller is resistant to wear in contaminated media.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Gasketed plate heat exchangers SIGMA

SIGMA plate heat exchangers have excellent design characteristics that ensure their durability and reliability. Plate heat exchangers use corrugated plates that are placed between a fixed and movable pressure plate. Due to the fact that almost all of the material is used for heat transfer, plate heat exchangers have a large effective heat transfer area with a minimum of space. Often, a plate heat exchanger can deliver the same heat transfer capacity as a shell-and-tube heat exchanger that is five times larger in volume.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

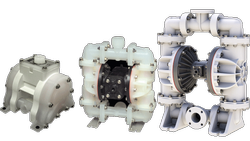

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

Washing pumps

Powerful and effective cleaning solutions

Washing pumps are important equipment that provides effective cleaning of surfaces from various types of dirt. These pumps are equipped with special mechanisms that provide high pressure of water or other liquids necessary to remove even the most stubborn deposits and dirt.

Applications in various fields

Industrial washing pumps have found wide application in various industries, such as the automotive industry, construction, agriculture, food industry and many others. They are used to clean cars, equipment, production facilities, as well as to maintain cleanliness and hygiene in various industrial and commercial facilities.

High performance and reliability

Industrial washing pumps are characterized by high performance and reliability. They are able to provide an intensive flow of liquid under high pressure, which allows you to effectively remove contaminants from surfaces. Due to their robust design and high-quality materials from which they are made, these pumps have a long service life and a high degree of reliability in operation.

Variety of models and characteristics

There are many models of industrial washing pumps on the market, differing in power, performance, pressure and other characteristics. A wide range of pumps is available to buyers, allowing them to choose the optimal solution for specific tasks and operating conditions.

Easy to use and maintain

Easy to use and maintain

One of the advantages of industrial flushing pumps is their ease of use and maintenance. They are easy to install and connect to a power source and water supply, and do not require complex maintenance. This makes the operation of these pumps convenient and cost-effective.

Effective solution for cleanliness and hygiene

The use of flushing pumps allows you to maintain a high level of cleanliness and hygiene at production facilities, vehicles and other places. This is especially important in environments where strict sanitary and safety regulations must be observed.

Conclusion

As a result, flushing pumps are indispensable equipment for ensuring cleanliness and hygiene in various industrial and commercial sectors. High performance, reliability and ease of use make them an attractive choice for business and production.