Pumps for Volumetric Dispensing

Volumetric metering pumps are specialised devices designed to accurately and evenly dispense liquid or gaseous products with a certain volume. They are widely used in various industries, medicine, pharmaceuticals and chemicals to automate the processes of mixing, dosing and feeding various substances. Volumetric dosing pumps provide high accuracy and stability of dosing, which minimises material losses and ensures high quality of the final product. They are equipped with special control and regulation systems, as well as various speed and volume settings, making them a versatile and reliable tool for various production tasks.

TOP-19 Pumps for volumetric dispensing + other products

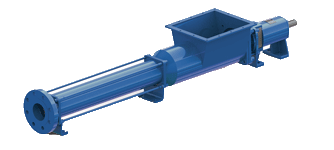

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

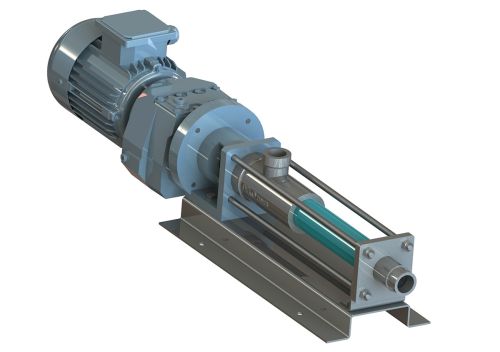

Screw dosing pump

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

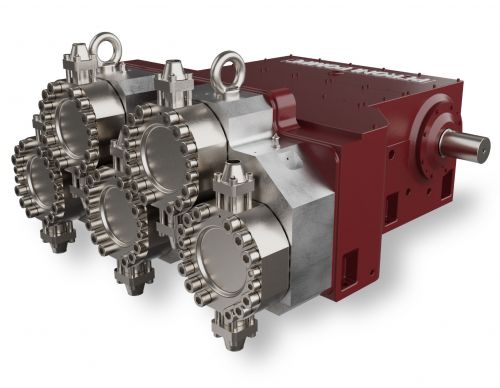

TITANO Series

The pumps of the TITANO series are designed and manufactured according to API 674 and ASME standards and cover the range of medium power up to 600 kW.

These pumps are studied to guarantee a highly reliable service and to minimize the maintenance operations and the operating costs.

The TITANO series consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex model are used.

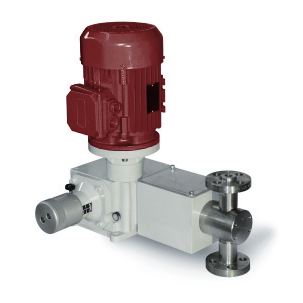

Simplex PD Plunger Pumps

The pumps in this series feature a mechanical plunger return stroke and have adjustable stroke settings from 0 to 100%, providing flexibility in operation and dosing accuracy of more than 1% over a performance range of 10 to 100%. These liquid dosing pumps maintain the required NPSH below 0.3 bar abs under standard conditions.

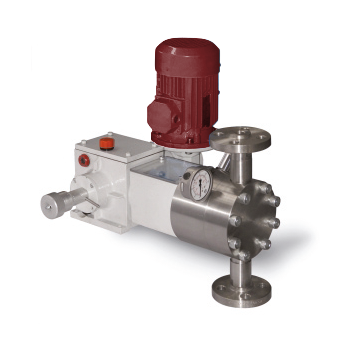

Simplex PD Diaphragm Pumps

The series is designed adopting hydraulically actuated double sandwich diaphragms with intermediate vacuum chamber lined with an oil film. This is the solution for handling any hazardous fluid and when stringent environmental regulations have to be met.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Process Diaphragm Pumps

Peroni's process diaphragm pumps are specially designed for offshore platform applications, with dimensions reduced by up to 25% compared to pumps from other manufacturers.

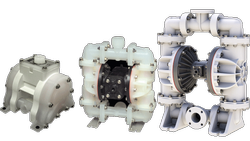

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Positive dosing pumps

Dosing accuracy

Positive dosing pumps provide high accuracy when dosing liquids or gases. This is especially important in industrial processes where strict adherence to certain proportions of components is required to achieve optimal product quality.

Feed uniformity

One of the key advantages of volumetric dosing pumps is the uniformity of material feed. This eliminates distortions and deviations in the production process, which significantly reduces the number of defects and increases work efficiency.

Wide range of applications

Industrial volumetric dosing pumps are designed to work with various types of liquids and gases, including aggressive chemicals and highly viscous materials. This makes them a universal tool in various industries, such as chemical, food, pharmaceutical and others.

Industrial volumetric dosing pumps

Reliability and durability

Industrial volumetric dosing pumps are characterized by high reliability and durability. Made of high-quality materials, resistant to corrosion and aggressive environments, which ensures a long service life and minimal maintenance costs.

Modern technologies

Modern industrial pumps for volumetric dosing are equipped with advanced technologies, such as automatic control and regulation systems, digital displays, as well as the possibility of remote control and monitoring. This ensures maximum efficiency and ease of use.

Positive dosing pump

Positive dosing pump

Easy to maintain

Positive dosing pumps have a simple design, which makes them easy to maintain and repair. They do not require complex adjustment and can be quickly replaced if necessary, which reduces downtime and increases productivity.

Economical

The use of volumetric dosing pumps allows you to reduce material consumption due to accurate and uniform dosing. This allows you to reduce production costs and increase the competitiveness of products in the market.

Compliance with standards

Industrial volumetric dosing pumps meet high quality and safety standards. They are certified and undergo strict quality control at all stages of production, which ensures safety and reliability of operation.