Pumps for Control

Control pumps are specialised devices used to measure and control the flow of liquids or gases in various processes and systems. They provide precise supply and control of the flow of the medium, which allows you to effectively manage production processes, maintain the required environmental parameters and ensure the safety and efficiency of technical systems. Control pumps are widely used in industry, construction, as well as in agriculture, medicine and scientific research. They can be equipped with various sensors, automation systems and software to monitor and control the processes of supplying and distributing liquids or gases.

TOP-7 Pumps for control + other products

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Multi-Function Electromagnetic dosing pump

Valisi electromagnetic metering pumps are suitable for dosing of all types of liquid products. All pumps are diaphragm pumps, which means they accurately dispense small, constant volumes of liquids or chemicals. In addition, their hermetic design allows them to self-drain after use, reducing the risk of leaks and clogging.

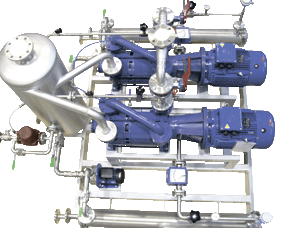

Liquid ring vacuum pump systems & centralized units

Liquid ring vacuum pump systems designed to meet most needs of vacuum of the industry. Developed with one or more pumps acting in parallel depending on the specific needs, the systems are equipped with dedicated equipment for service liquid cooling and recirculation including instrumentation and devices for control and full remote automatic operation including control panel with PLC and VFD. Units for hazardous area, on request.

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Control Pumps

Control pumps play a key role in various industries and ensure effective control of the supply and distribution processes of liquids or gases. They are specialized devices designed to measure and regulate the flow of the medium, ensuring accurate supply and flow control. These pumps are widely used in various fields such as manufacturing, energy, agriculture, construction and others.

Industrial Control Pumps

Industrial control pumps are designed specifically for use in difficult industrial conditions. They are characterized by high reliability, performance and durability, which makes them an ideal choice for industrial enterprises. These pumps can handle various types of liquids and gases, ensuring stable and efficient operation of technical systems.

Control pump

Control pump

A control pump is an integral part of many production processes and systems. It provides precise control of the flow rate of the medium and allows you to maintain the required parameters in operating conditions. Pumps of this type are usually equipped with various sensors and automation systems, which ensures reliable and efficient operation of the control system. Control pumps are important technical equipment that plays a key role in ensuring the safety, efficiency and reliability of production processes. Choosing the right pump depends on specific needs and operating conditions, so before buying, you must carefully study the characteristics and features of each model.