Pumps for Measuring

Measurement pumps are specialised equipment used to accurately and consistently measure the flow of liquids or gases. These pumps play a key role in a variety of industrial processes, laboratory research and other industries where the flow of a medium needs to be monitored and controlled. They provide high measurement accuracy and reliable operation, enabling reliable data for analysis and decision-making. Measurement pumps are available in a variety of configurations and types, including peristaltic, diaphragm, centrifugal and other types, allowing you to choose the best solution for your specific application and operating conditions. They are widely used in industries such as chemicals, oil and gas, medicine, and scientific research to measure and control the flow of various liquids and gases.

TOP-7 Pumps for measuring + other products

Oscillating piston flowmeter

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

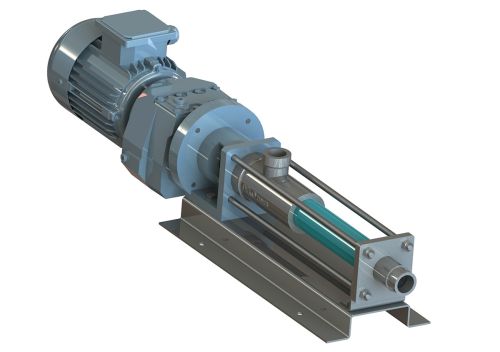

Screw dosing pump

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Metering Pumps: An Overview

Metering pumps are specialized equipment used to accurately and consistently measure the flow of liquids or gases. These pumps play a key role in various industries, laboratory research, and other areas where the control and management of the flow of a medium is required. They provide high measurement accuracy and reliable operation, which allows you to obtain reliable data for analysis and decision-making.

Advantages of industrial metering pumps

- High accuracy: industrial metering pumps have high measurement accuracy, which allows you to obtain accurate and reliable data;

- Wide range of applications: these pumps can be used in various industries, including the chemical industry, the oil and gas sector, medicine and scientific research;

- Reliability and durability: industrial metering pumps are made of durable materials and have a high degree of reliability and durability;

- Variety of models: there are many different models of metering pumps on the market, which allows you to choose the optimal solution for specific tasks and operating conditions.

Choosing a metering pump

When choosing a pump for measurement, several key factors should be considered:

When choosing a pump for measurement, several key factors should be considered:

- Type of measured medium: the choice of the pump should correspond to the type of measured medium, its physical and chemical properties;

- Measurement accuracy: it is necessary to choose a pump with sufficient accuracy for the required measurements;

- Performance and pressure: consider the required pump performance and pressure to ensure the effective operation of the measurement system;

- Operating conditions: the pump must be adapted to the operating conditions, including temperature conditions and aggressive environments.

By choosing the right pump for measurement, you can be sure of the accuracy and reliability of the measured data, which is a key point for the efficiency of your process or research.