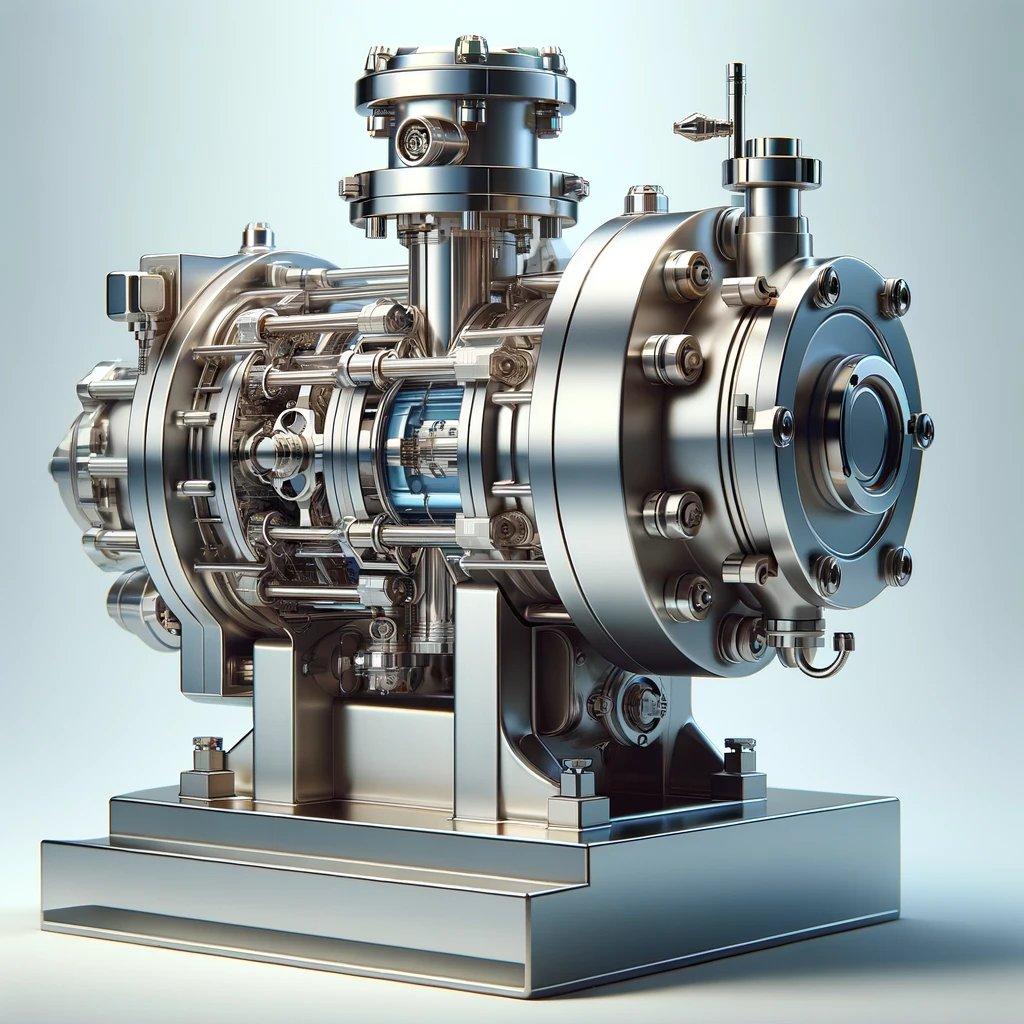

SIP pumps

SIP pumps, or pumps for in site sterilisation systems, are an integral part of processes in industries where a high level of hygiene and sterility is required. These specialised pumps are designed to transfer clean and sterile media with high precision and safety to ensure the safety and quality of production in the food, pharmaceutical and other sensitive industries. SIP pumps have special characteristics such as compatibility with aggressive chemicals and resistance to high temperatures and pressures, which allows them to operate in the most demanding production environments. It is important to choose the right SIP pump for your specific production requirements to ensure the efficiency and safety of your sterilisation and production processes.

TOP-6 Sip pumps + other products

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

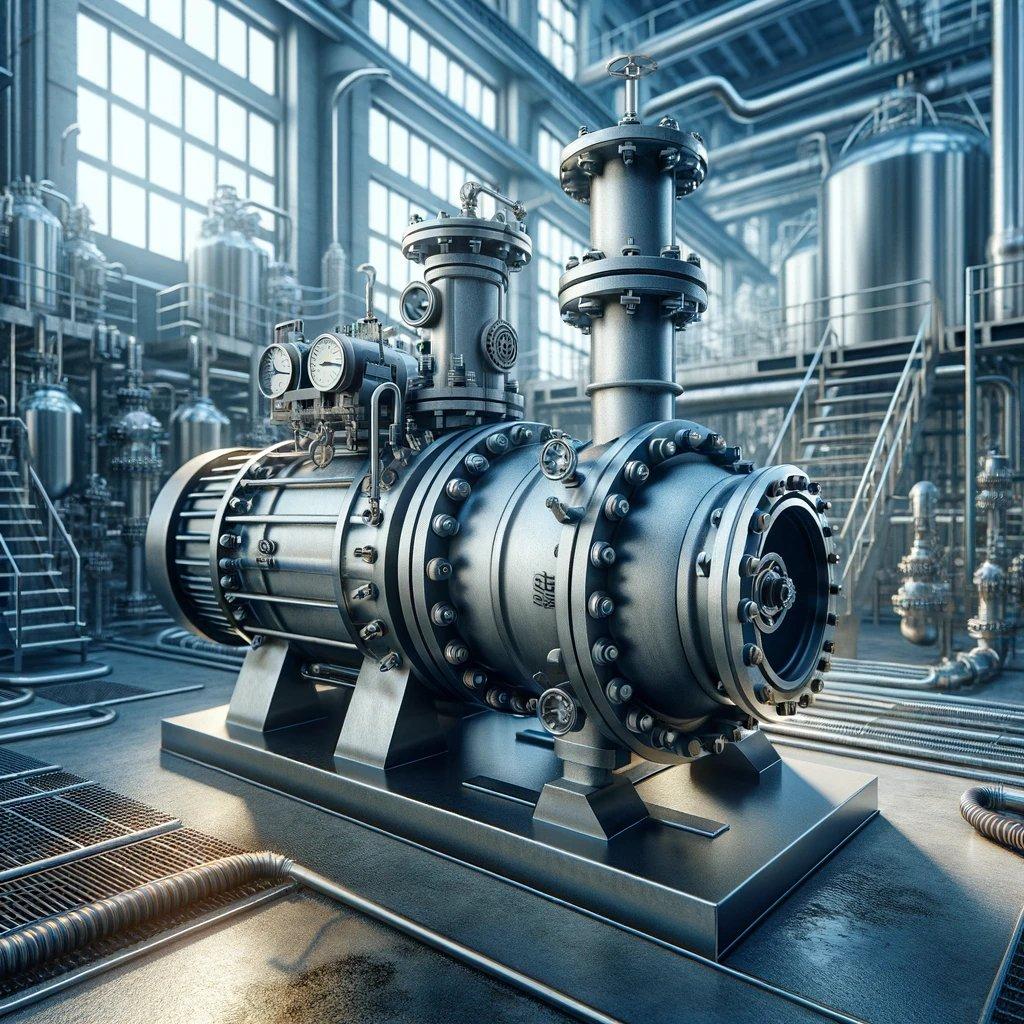

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Sinus Sodial Pumps

SOMA SINUS SODIAL® is a positive displacement pump. The peculiarity of the pumps is that the chambers are a single unit during movement, and their volume does not change during the pumping process; therefore, the pumped medium is not subjected to any significant mechanical stress. Due to the minimal deformation of the liquid, the pump is capable of pumping highly viscous substances.

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

SIP Pumps: Key Features and Benefits

The Role of SIP Pumps in Industry

SIP pumps, or Sterilization-in-Place System Pumps, play a key role in manufacturing processes where high levels of hygiene and sterility are required. These specialized pumps are designed to transfer sterile media with high precision and safety, ensuring safety and quality of production in various industries, including the food, pharmaceutical and biotechnology industries.

Benefits of using SIP pumps

One of the main advantages of SIP pumps is their ability to ensure a high degree of sterility in production processes, which significantly reduces the risk of product contamination by microorganisms or other impurities. Thanks to special design solutions and materials, SIP pumps have high resistance to aggressive chemical environments and high temperatures, which allows them to function successfully in the most extreme production conditions.

Choosing the right pump for a sterilization system

When choosing a pump for a sterilization system, a number of factors must be taken into account, including the production requirements for the level of sterility, the volume of the pumped medium, technical characteristics and requirements for the operating environment. It is important to choose a pump that best suits the specifics of production and ensures the efficiency and safety of sterilization processes.

Applications of SIP pumps in various industries

SIP pumps are widely used in various industries. In the food industry, they are used to pump sterile liquids such as juices, milk and other products. In the pharmaceutical industry, SIP pumps are essential for the production of pharmaceuticals and other pharmaceutical products, where a high level of sterility is critical to ensuring product safety and efficacy.

Maintenance and Support for SIP Pumps

To ensure long-term and trouble-free operation of SIP pumps, regular maintenance and support are required. This includes checking and replacing worn parts, adjusting pump parameters, and training personnel on the correct operation and maintenance of the equipment. It is also important to have access to qualified technical support from the manufacturer or supplier to promptly resolve any problems and ensure continuity of production processes.