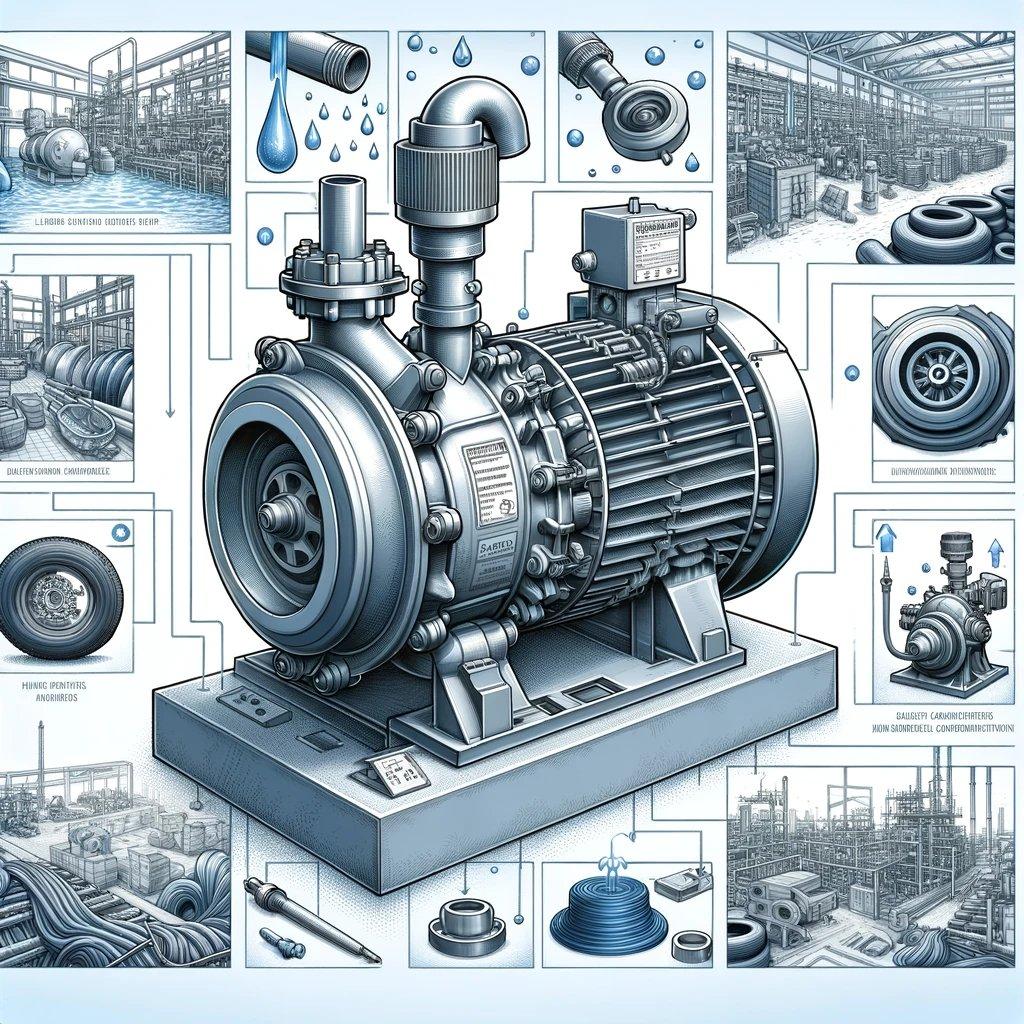

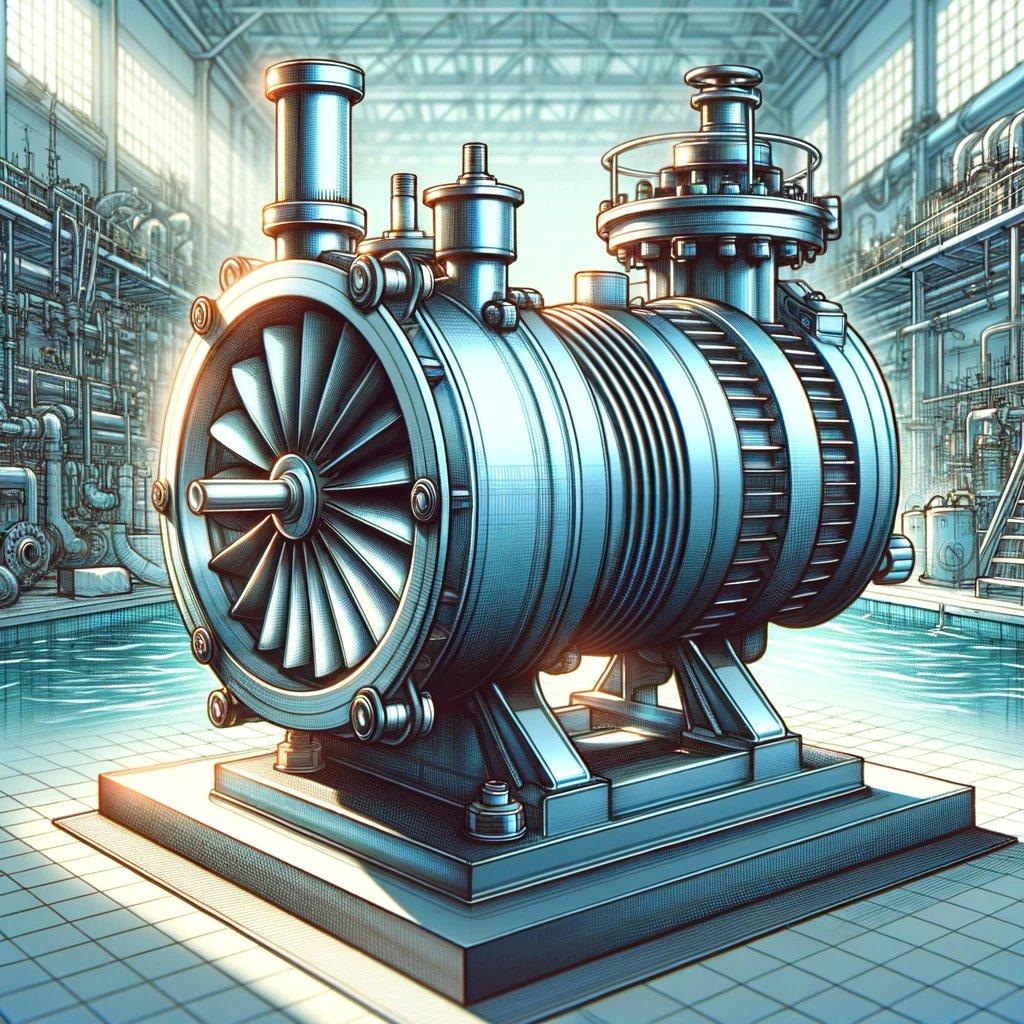

Pumps for Rubber

Rubber pumps are specialized equipment designed for pumping rubber mixtures and rubber-containing liquids in industrial processes. These pumps have a special design and materials resistant to aggressive rubber components, ensuring reliable and efficient operation when processing and pumping rubber materials. They are used in various industries, including rubber plants, tire production, rubber enterprises and other areas where accurate and safe pumping of rubber mixtures is required for the production of various products. Rubber pumps play an important role in ensuring the continuity of production processes and high quality of the final product.

TOP-6 Pumps for rubber + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

High-pressure homogeniser Rannie/Gaulin

The equipment required for a homogeniser includes all components that can grind liquid particles, resulting in a homogeneous and stable product emulsion. Industrial and laboratory high-pressure homogenisers are direct-acting piston pumps equipped with a pressing unit and a homogenising valve, which can be used in various industries and improve product quality and stability.

What should a homogeniser be used for? Homogenisers are widely used in the dairy, food, healthcare, cosmetic, chemical, biotechnology and pharmaceutical industries. They can provide significant added value, improved product quality and competitive advantage. Systems can be designed and configured to offer specific product characteristics, including:

- Significantly improved product palatability

- Particle size control for more homogeneous, finer emulsions

- Reduced amount of emulsifiers and stabilisers required

- Improved binding to water

- Improved colour properties

- Homogeneous emulsions

- Creams and lotions that are easier to apply

Rubber Pumps: Essential Equipment in the Rubber Industry

Advantages of Industrial Rubber Pumps

Rubber pumps are specialized equipment that play a key role in the rubber industry. They have a number of advantages that make them an integral part of production processes:

- High performance: industrial rubber pumps ensure efficient and continuous pumping of rubber mixtures, which increases production productivity.

- Reliability: They have a robust design and high-quality components, which ensures a long service life and minimizes the risk of breakdowns and failures.

- Versatility: Rubber pumps can be used in various branches of the rubber industry, such as tire production, rubber products, conveyor belts and other rubber products.

- Precision and control: They ensure precise and controlled pumping of rubber mixtures, which allows you to maintain high quality of the final product.

Key Features of Rubber Pumps

Industrial rubber pumps have a number of unique features that make them indispensable equipment in the rubber industry:

- Special materials: they are made of materials resistant to aggressive rubber components, which ensures durability and reliability in operation.

- Variety of models: there are many different models of rubber pumps adapted to different types of rubber compounds and conditions of their use.

- Efficiency and cost-effectiveness: they work efficiently and save energy, which allows you to reduce production costs.

Applications of rubber pumps

Rubber pumps are widely used in various branches of the rubber industry:

- Tire production: they are used for pumping and mixing rubber compounds necessary for the production of automobiles, bicycles and other types of tires.

- Rubber product production: pumps of this type are used for the production of rubber parts, seals, gaskets, belts, etc.

- Rubber conveyor belt production: They are used to pump rubber mixtures required for the production of conveyor belts, which are widely used in industry and logistics.

Conclusion

Rubber pumps are an important link in the production chains of the rubber industry. Their high performance, reliability and versatility of application make them indispensable equipment for enterprises engaged in the production of tires, rubber products and other rubber products.