Pumps for low NPSH

Low NPSH pumps are specialised devices designed to operate in environments where the available suction head is insufficient to prevent cavitation, the formation of vapour bubbles in the pump due to a pressure drop below the partial pressure of the liquid. Such pumps typically feature an enlarged inlet size and improved design of the working parts to minimise the risk of cavitation and ensure efficient operation in low NPSH environments. They are widely used in a variety of industries such as oil and gas, chemical, power and water where low NPSH can be a problem due to high suction depths, high temperatures or aggressive chemical environments. When selecting pumps for low NPSH environments, it is important to consider performance, reliability and safety requirements, and to provide regular service and maintenance to ensure the equipment is running smoothly.

TOP-8 Pumps for low npsh + other products

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

Single-stage centrifugal pumps

The product range includes chemical single-stage horizontal centrifugal pumps, horizontal monoblock centrifugal pumps, vertical single-stage centrifugal pumps, single-stage in-line centrifugal pumps and double-suction in-line pumps.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

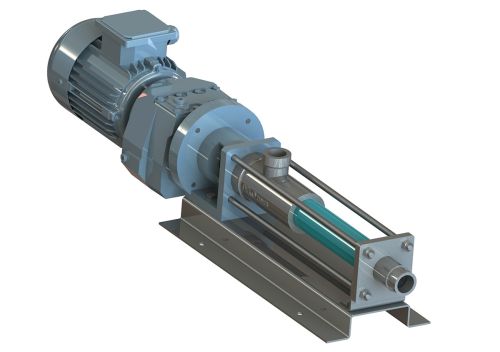

Screw dosing pump

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Pumps for low NPSH conditions: The efficient solution for challenging conditions

The benefits of using low NPSH pumps

Low NPSH pumps are specialized devices that are designed to operate efficiently in conditions where the available suction head is insufficient to prevent cavitation. They provide reliable and safe operation even at low NPSH, minimizing the risk of cavitation and ensuring the stability of pumping processes.

Characteristics of industrial pumps for low NPSH applications

Low NPSH industrial pumps have a number of special features that make them indispensable equipment for demanding environments. They often have an enlarged inlet size, special geometry of working parts and improved cooling systems that allow them to operate efficiently at low pressures and high temperatures.

Applications for low NPSH pumps

Low NPSH pumps are widely used in a variety of industries, including oil and gas, chemical production, power generation and water supply. They are used for pumping aggressive media, working with large suction depths and ensuring stable pumping processes even under difficult operating conditions.

Selecting a pump for low NPSH applications

When selecting a pump for low NPSH applications, it is important to consider the requirements of the specific application, the media, production volumes and operating environment. In addition, regular maintenance and support should be provided to ensure the equipment is running smoothly.

Conclusion

Low NPSH pumps play an important role in ensuring the stability and reliability of pumping processes in demanding environments. The correct selection and operation of pumping equipment helps to minimize the risks of cavitation and ensure efficient operation in a variety of industries.