Meat pumps

Meat pumps are specialised equipment designed to pump and process meat mass in the food production process. They play a key role in the meat processing industry, ensuring the efficient movement of meat along production lines and its further processing. Meat pumps have specific characteristics that allow them to work with different types of meat and provide high performance while meeting strict hygiene and safety standards. They can be used to transfer meat mass, sauces, marinades and other ingredients in the process of cooking meat products. When choosing meat pumps, it is important to consider performance, hygiene and product compatibility requirements, and to ensure regular maintenance and technical support to keep the equipment running smoothly.

TOP-9 Pumps for meat + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

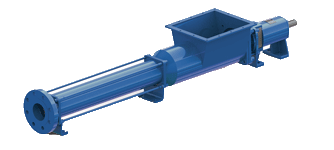

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Pumps for meat: Essential equipment in the food industry

Pumps used in meat processing must handle viscous, solid-laden, and sometimes fragile products like minced meat, blood, fat, and slurries. These pumps ensure hygienic, efficient, and damage-free transfer of meat-based materials in food processing plants.

Characteristics of industrial meat pumps

Industrial meat pumps have special characteristics that make them the ideal choice for the production of meat food products. They are able to work with high viscosity meat masses and provide reliable and accurate pumping even with large volumes of product. In addition, these pumps are easy to clean and disinfect, which is important for maintaining hygiene standards.

Types of Pumps for Meat Processing

Progressive Cavity (Screw) Pumps

- Best for minced meat, emulsions, and viscous meat mixtures.

- Provide gentle handling, preventing product damage.

- Maintain a steady flow, reducing air pockets.

Lobe Pumps

- Ideal for meat slurries, pâtés, and sausage fillings.

- Sanitary design, easy to clean (CIP/SIP compatible).

- Gentle on product while maintaining high efficiency.

Diaphragm Pumps

- Suitable for blood, fats, and semi-solid waste.

- Handle abrasive and sticky substances without clogging.

- Air-operated versions are popular in meat processing plants.

Piston Pumps

- Used for high-pressure transfer of ground meat or sausage stuffing.

- Excellent for portioning applications.

- Maintains texture without excessive grinding.

Centrifugal Pumps

- Best for low-viscosity fluids like broth, stock, and rendered fats.

- High-speed operation but not ideal for solid-rich mixtures.

Key Considerations When Choosing a Meat Processing Pump

- Material: Food-grade stainless steel (AISI 316 preferred for hygiene and corrosion resistance).

- Hygiene Compliance: Must meet FDA, USDA, EHEDG, or 3-A sanitary standards.

- Cleaning Capabilities: Easy disassembly or CIP (Clean-in-Place) compatibility.

- Viscosity & Solid Handling: Ensure the pump can handle meat chunks, bones, or fibrous content if needed.

- Flow Rate & Pressure: Depends on production scale and application (e.g., portioning, transferring, or filling).

Conclusion

Meat pumps are an important link in the production of meat products, providing reliable and efficient pumping of meat mass and other ingredients. The right choice and use of pumping equipment helps producers maintain product quality and comply with safety and hygiene standards.