Pumps for Biodiesel

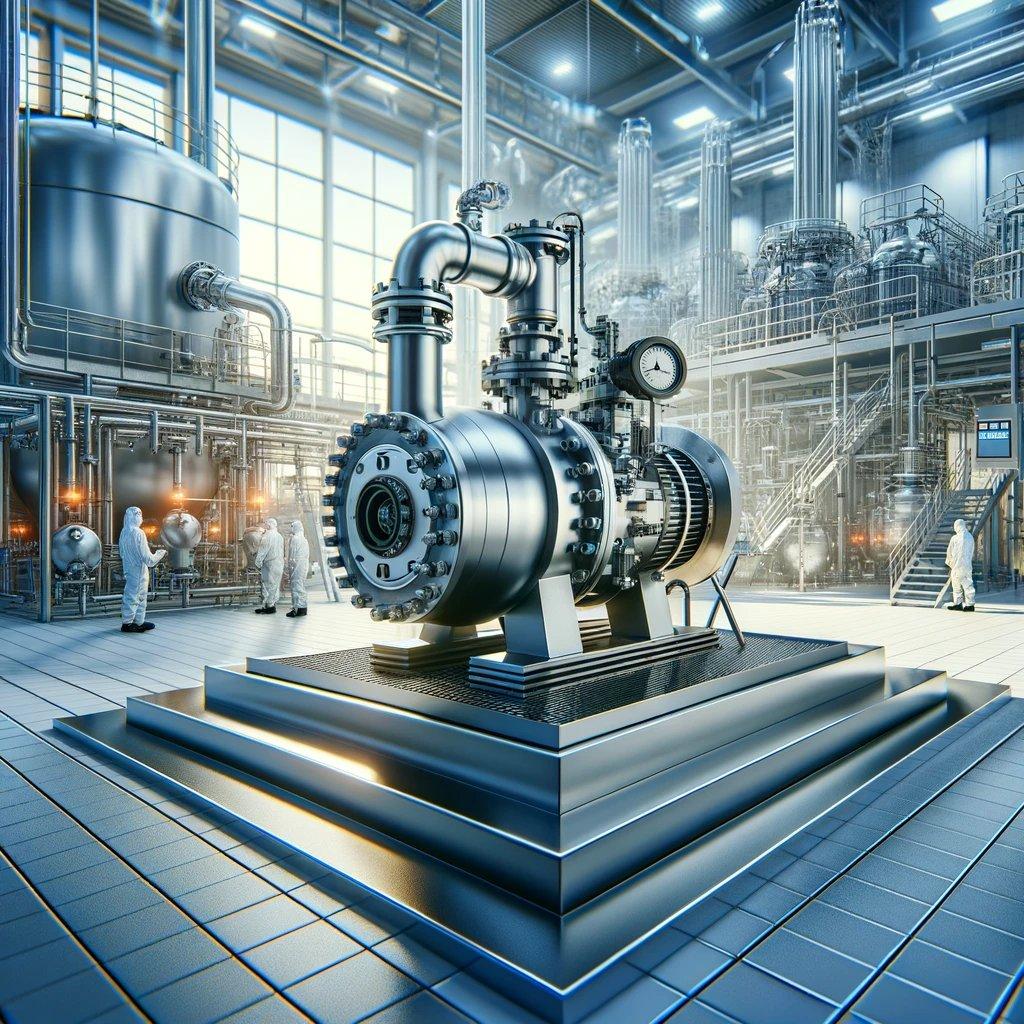

Biodiesel pumps are special devices designed for pumping and handling biodiesel. They play a key role in the production, transportation and distribution of biodiesel products. Industrial biodiesel pumps are highly efficient and reliable, which ensures smooth and safe operation of the entire process. Biodiesel pumps are designed for use in a variety of industries, including biodiesel production, as well as in agriculture, transport and other areas where a biodiesel-based fuel system is required. They are usually made of special materials that are resistant to the aggressive chemical compositions of biodiesel fuel to ensure durability and safe operation. Biodiesel pumps are available in a variety of models and configurations to meet specific needs and application conditions. They play an important role in ensuring the efficient and sustainable use of biodiesel, helping to reduce the environmental impact and providing the prospects for the development of cleaner forms of energy.

TOP-9 Pumps for biodiesel + other products

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

Drum/Barrel Pumps

FINISH THOMPSON is one of the leading manufacturers of barrel pumps and a specialist in centrifugal pumps in general. The range of drum pumps includes plastic and metal models used for emptying containers, barrels, tanks, medium-duty containers and hoppers. The range of centrifugal pumps includes stainless steel pumps, ETFE-coated process pumps, plastic pumps made of polypropylene and PVDF for aggressive, difficult chemicals.

Pumps for Biodiesel

Biodiesel pumps are essential equipment for pumping this alternative video fuel. Biodiesel is an environmentally friendly and renewable source of energy, so the demand for it is constantly growing. This makes biodiesel pumps a key element in the production, transport and storage of this fuel.

Industrial biodiesel pumps

Industrial biodiesel pumps have special characteristics that make them the ideal choice for use in a variety of industrial sectors. They are designed with biodiesel in mind and are designed for high performance, reliability and durability. These pumps are usually made of special materials that provide resistance to aggressive biodiesel formulations and prevent corrosion and wear.

Biodiesel pump

A biodiesel pump is a necessary equipment to ensure the efficient and safe transfer of biodiesel fuel. It ensures stable operation of the entire pumping system, as well as convenience and ease of use. Biodiesel pumps are available in various types and configurations to meet different needs and applications, including stationary and mobile options.

The selection of the right biodiesel pump for your application depends on many factors, including the volume of fuel to be pumped, operating pressure, speed and other parameters. When choosing a biodiesel pump, it is important to pay attention to its technical characteristics, the quality of the materials it is made of, as well as the availability of certifications and compliance with safety standards.

The selection of the right biodiesel pump for your application depends on many factors, including the volume of fuel to be pumped, operating pressure, speed and other parameters. When choosing a biodiesel pump, it is important to pay attention to its technical characteristics, the quality of the materials it is made of, as well as the availability of certifications and compliance with safety standards.

Biodiesel pumps play a key role in ensuring the efficient use of this environmentally friendly fuel, helping to reduce emissions of harmful substances into the atmosphere and improve the overall environmental situation. Therefore, choosing the right biodiesel pump is an important step for those who care about the environment and want to save resources.