Pumps for Concrete

Concrete pumps play a key role in the construction industry, ensuring efficient and accurate delivery of concrete mix to construction sites. These specialised pumps can pump concrete over long distances and heights, ensuring high productivity and quality of construction work. They are typically equipped with powerful pumping mechanisms and hydraulic systems capable of handling the high viscosity of the concrete mix and ensuring its even distribution on the construction site.

TOP-3 Pumps for concrete + other products

Hose pumps VPH series

The VPH series of peristaltic pumps with shoe technology is our updated peristaltic pump designed for high pressure applications up to 15 bar, with 14 sizes available in flow rates up to 150 m3/h. This is a heavy-duty industrial pump series designed for round-the-clock operation. We have combined the best available materials with clever design solutions to maximise uptime and minimise maintenance.

This pump summarises what we want to achieve: the best pumping solutions for our customers. Our design increases the simplicity and reliability of the pump.

Metallic AOOD Pump

Pneumatic diaphragm pump for standard operating conditions are one of the most popular series on the market. They are available in a wide range of sizes (1/4" - 3") and are used to handle general-purpose liquids such as clean water, process water, mildly aggressive liquids, liquids with a moderate content of small inclusions, oil products, etc. They are often used in the ceramic, chemical and paint and varnish industries, as well as in the wastewater and utilities sectors.

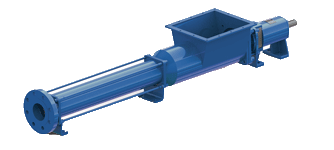

Hopper pumps

The design of the pumps allows them to be used for many different applications. The standard design includes an enlarged rectangular inlet hopper with a screw conveyor that pushes the product to be pumped into the pump's working section. There are versions in which the pump inlet is equipped with a large screw, an integrated cork breaker or both. Most pumps are supplied in a monoblock design (direct connection of the pump to the electric motor) or with a free shaft outlet (without an electric motor).

Pumps for Concrete

Concrete pumps are specialized equipment designed to pump concrete mixtures to construction sites. They play a key role in the construction industry, ensuring efficient and even distribution of concrete on the construction site.

Industrial concrete pumps

Industrial concrete pumps are powerful and reliable equipment specially designed for use in construction site environments. They are equipped with a powerful engine and hydraulic system that ensure high performance and reliability.

Pumps for concrete

A concrete pump is a device that delivers concrete mix from a concrete pump to its destination. It is usually mounted on a truck chassis and has a special mechanism for delivering concrete under pressure.

When choosing a concrete pump, it is important to pay attention to such parameters as capacity, delivery range, pressure, type of drive (hydraulic or mechanical), as well as the availability of additional features such as automatic concrete flow control and overload protection.

The use of concrete pumps can significantly increase the productivity of work on a construction site, reduce the time required to supply and distribute concrete, and improve the quality and durability of building structures.

The use of concrete pumps can significantly increase the productivity of work on a construction site, reduce the time required to supply and distribute concrete, and improve the quality and durability of building structures.