Pumps for aviation

A pump for aviation is a specialised equipment designed for pumping fuel, oils, hydraulic and other liquids in aircraft. Highly reliable and efficient, industrial aviation pumps ensure the smooth functioning of all aircraft systems.

TOP-8 Pumps for aviation + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

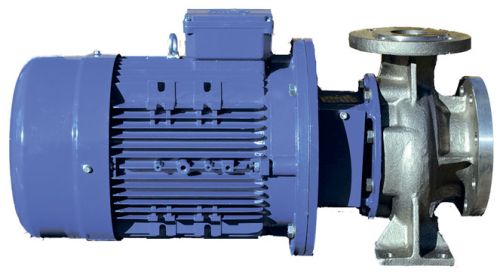

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

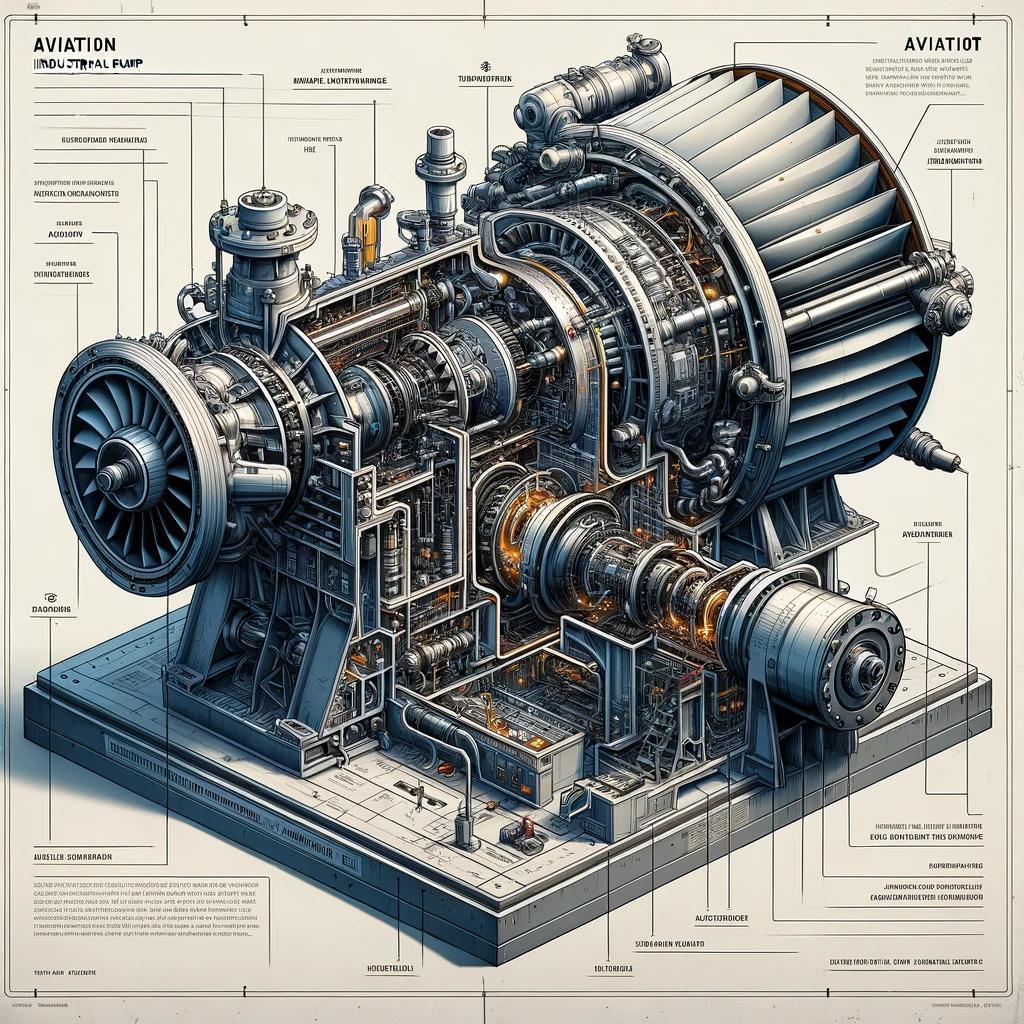

The importance of industrial pumps for aviation

The importance of industrial pumps for aviation

Reliability and safety

The aviation pump plays a key role in ensuring the reliability and safety of flights. It ensures a steady supply of essential fluids to critical aircraft systems, including engines and hydraulic systems.

Operational efficiency

Industrial pumps for aviation help to improve the efficiency of aircraft, reducing operating costs and maximizing productivity.

Key characteristics of a pump for aviation

Types of pumps

- Centrifugal pumps are ideal for transferring fuel due to their ability to generate high pressure with relatively low power consumption.

- Gear pumps are used to transfer oils and hydraulic fluids due to their high reliability and durability.

- Diaphragm pumps provide precise dosing and pumping of chemically active liquids without the risk of leakage.

Execution material

The choice of material for a pump is critical to ensure its durability and compatibility with the fluids being pumped. Pumps are made of high-strength alloys such as stainless steel, titanium and special polymers that are resistant to corrosion and chemical attack.

Performance and efficiency

The efficiency of a pump is determined by its ability to deliver the required volume and pressure of a fluid with minimal energy consumption. Important parameters include pumping speed, power consumption and pump efficiency.

Selection and Purchase of a Pump for Aviation

Defining the requirements

Before selecting a pump, it is important to clearly define the requirements for its operation, including the type of fluid to be pumped, the required pressure and volume.

Study the market offers

It is recommended that you conduct a thorough analysis of offers from different manufacturers, comparing technical specifications, price and feedback from other customers.

Selecting a Manufacturer and Supplier

Selecting a reliable manufacturer and supplier is critical to ensuring the quality and reliability of your aircraft pump. Give preference to companies with a good reputation, a wide range of products, and quality service.

Maintenance and repair

Maintenance and repair

Regular maintenance

To ensure long-term and trouble-free operation of the pump, it is necessary to carry out regular maintenance, which includes checking, cleaning and, if necessary, replacing worn parts.

Professional repair

In the event of a pump breakdown or malfunction, it is important to contact qualified specialists with experience in aircraft pumps for professional repair and restoration.

Conclusion

The pump for aviation is an integral part of the aircraft system, ensuring reliable and efficient operation of all its systems. The right choice, high-quality maintenance and timely repair of aviation pumps guarantee the safety and efficiency of flights. By paying attention to the quality and characteristics of aviation pumps, you contribute to the durability and reliability of aviation equipment.

Remember that choosing an aviation pump should be based on a thorough analysis of your needs and specifications, as well as trust in the manufacturer and supplier. Investing in high-quality equipment today will ensure the safety and efficiency of your aviation operations in the future.