Pumps certified ISO 14001

ISO 14001-certified pump is equipment that complies with the international standard ISO 14001 for environmental management. This certificate confirms that the pumps are manufactured in compliance with high standards of environmental safety and efficient use of resources. These pumps have a minimal impact on the environment, making them an attractive choice for environmentally responsible businesses and organisations.

TOP-6 Pumps certified ISO 14001 + other products

Industrial Progressive Cavity Pump

The pumps are used in various enterprises, industries, in the most difficult operating conditions, ensuring smooth fluid transfer. The pumps are suitable for pumping liquids with low and high viscosity, as well as for pumping abrasive, sticky, crushing and foaming liquids. The pumps are particularly suited for handling products with solid particles. The suction capacity is max. 5m/s. The pumps deliver regular, linear, pulsation-free and measured flow. Quiet operation without vibration.

PTO/PQO/PSO series

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

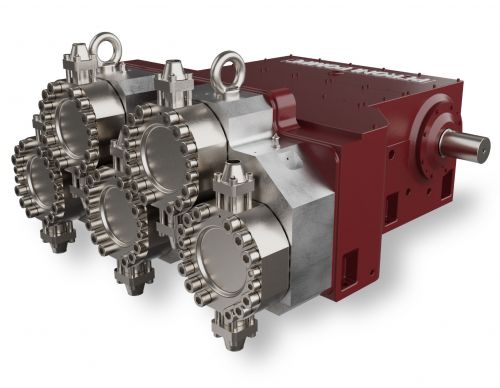

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Process Diaphragm Pumps

Peroni's process diaphragm pumps are specially designed for offshore platform applications, with dimensions reduced by up to 25% compared to pumps from other manufacturers.

ISO 14001 Certified Pumps

ISO 14001 certified pumps are designed with environmental and resource management in mind. They are highly reliable and durable, making them an attractive choice for a variety of industrial and commercial applications.

Benefits of ISO 14001 Certification

ISO 14001 certification of pumps confirms their compliance with international environmental standards. This means that these pumps are designed and manufactured with minimal impact on the environment and in compliance with the principles of sustainable development.

Characteristics of pumps certified according to ISO 14001

Industrial pumps certified according to ISO 14001 have a number of advantages:

- Environmental safety: they operate with minimal emissions of harmful substances, which is important for compliance with environmental standards and regulations.

- Efficient use of resources: ISO 14001 certified pumps ensure optimal use of energy and water, which reduces operating costs.

- Durability and reliability: thanks to the high quality of materials and technologies, these pumps have a long service life and minimal probability of breakdowns.

ISO 14001 certified pump applications

ISO 14001 certified pump applications

ISO 14001 certified pumps are widely used in various industries, including:

- Industrial production: using ISO 14001 certified pumps helps to comply with environmental regulations and reduce environmental impact.

- Water supply and water treatment: these pumps are effectively used for pumping water and treating wastewater, ensuring the purity and safety of water resources.

- Energy and heating: in heating and ventilation systems, ISO 14001 certified pumps help to reduce energy consumption and increase energy efficiency.

Choosing pumps certified to the ISO 14001 standard ensures not only high performance and environmental safety, but also compliance with modern requirements for sustainable development and responsible use of resources.