Pumps for Greasing

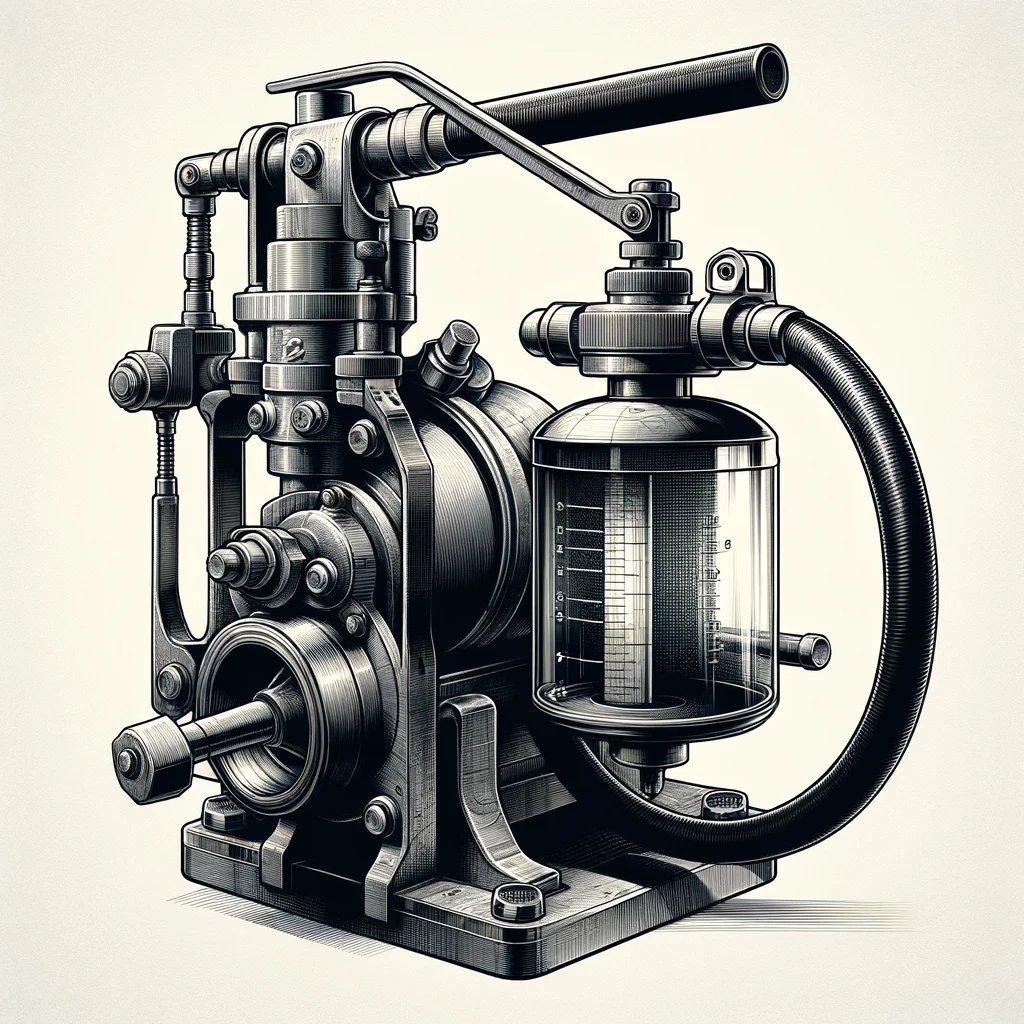

Pumps for greasing are specialised devices designed to pump lubricants, such as oil or grease, into mechanical devices to lubricate their moving parts. These pumps are widely used in industry, automotive, agriculture and other sectors where it is necessary to ensure proper lubrication and protect mechanisms from wear and damage. Lubrication pumps provide an even and precise distribution of lubricants throughout the equipment being processed, which helps to increase efficiency and extend the life of the machinery. They offer a variety of pump types, including gear, gear, centrifugal and plunger pumps, allowing you to choose the most suitable option depending on your specific needs and operating conditions.

TOP-6 Pumps for greasing + other products

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Internal eccentric gear pump

Internal gear pumps of the VD series are positive displacement pumps with a robust and simple design (only two moving parts). This type of design allows for efficient pumping of both liquid and clean media, as well as highly viscous abrasive media with inclusions (e.g. asphalt, chocolate, honey, etc.). The pumps can pump liquids with a viscosity of 100 ~ 1.000.000 cst. The pumps provide a uniform flow and high pressure. The following gear pump designs are available: without axial support, with axial support, in-line design, monoblock design, and high-speed design.

Lubrication Pumps: Overview and Applications

Benefits of Using Lubrication Pumps

Lubrication pumps play a key role in ensuring efficient and reliable lubrication of mechanisms and equipment. They ensure uniform distribution of lubricant throughout the mechanism, which helps prevent wear and damage, increases the service life of equipment and reduces the likelihood of downtime and accidents.

Variety of Types of Lubrication Pumps

There are several types of lubrication pumps, each of which has its own features and advantages. The most common types of pumps include gear pumps, gear pumps, centrifugal pumps, and plunger pumps. Each of these types is suitable for certain operating conditions and production requirements.

Characteristics of industrial lubrication pumps

Industrial lubrication pumps are characterized by high performance, reliability, and durability. They are designed to operate under high loads and high temperatures, making them an ideal choice for use in industrial processes.

Choosing a lubrication pump: what to consider

When choosing a lubrication pump, there are several key factors to consider. It is important to determine the type of lubricant, the required pump performance, operating conditions, and reliability requirements. It is also worth paying attention to the compactness and energy efficiency of the selected model.

Applications of lubrication pumps

Applications of lubrication pumps

Lubrication pumps are widely used in various industries, including mechanical engineering, automotive, mining, agriculture and other industries. They are used to lubricate bearings, transmission mechanisms, agricultural machinery and other equipment where reliable and effective lubrication is required.

Conclusion

Lubrication pumps are an important component of many production processes, ensuring proper lubrication and protecting equipment from wear and damage. When choosing a pump, it is necessary to take into account the specific characteristics of the specific task and operating conditions to ensure optimal performance and durability of the equipment.